If you are planning to make repairs on the balcony or loggia, then, perhaps, the issue of interior decoration has become one of the most relevant for you. I want the materials to be inexpensive, the skin is practical and beautiful, and the installation work is free? If so, then you suitable The option of lining the balcony with wooden lining (or plastic). Wooden panels will perform the function of additional insulation, of which various chemicals will not evaporate for years, as from synthetic materials of dubious quality, and a fungus will not appear under them. Generally all just, environmentally friendly and as aesthetic as possible.

Content

- What is a lining

- Types and classes of wooden lining

- Log: breeds of wood

- What is a plastic lining

- Necessary materials and tools

- Preparing a balcony or loggia for lining

- Installation of the crate

- Laginon upholstery by lining

- The finish processing of the lining

- Mounting Europe: Video

- Balcony trim with lining: photo

What is a lining

Log - everyone well -known finishing material made of natural wood, which implies grand-grown a method of fastening, which work with which maybe Each homeowner without involving specialists of the construction profile.

Name own The material received due to the fact that this type of board was originally used for the interior decoration of passenger cars.

There are a lot of advantages:

- it does not block the microcirculation of air, because as you know, The tree "breathes";

- creates additional insulation;

- absorbs excess moisture, if air raw and evaporates her — if air overdry;

- the room is filled with a natural smell of wood;

- the material is resistant to decay during proper processing;

- processing amenable easily;

- well tolerates temperature changes;

- provides reliable noise insulation;

- under the lining can be hidden the wires necessary for communications;

- and v the end, she just looks great .

Types and classes of wooden lining

Manufacturers divide the material into classes depending on the quality of wood. At the same time, there is no difference in the processing or production of the lining of different classes.

- Extraclass. Such wood has no defects in the form of knots or natural cracks. Color her uniform and homogeneous, often light. Thanks to processing, such a lining does not crack, does not deform over time, has a minimum level of shrinkage and at the same time maximum density. It is logical to assume that the cost of the material extra-class It will be quite high.

- Class A (first variety). It may have inclusions in the form of living light knots.

- Class IN (second variety). Often has inclusions in the form of inanimate dark Brachkov.

- Class WITH (Third variety). Such wood can have fallen knots, through cracks.

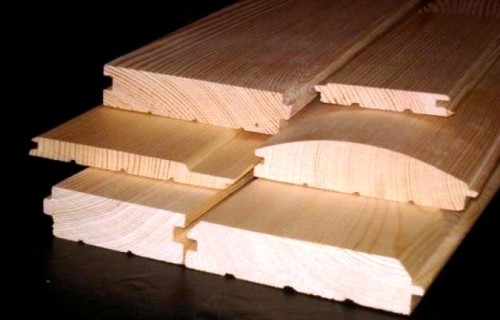

Except classes that note the quality of wood, the material will be divided into ordinary and euro -car - the differences between which are mainly noted by the size of the board:

- normal facing lining: width 15 cm, length - to 6 m, thickness - up to 2.5 cm;

- eVERENTS: Width 8 —12 cm; length from 50 cm to 6 m, thickness - from 1.3 to 1.9 mm .

As you can see, the Eurolanka is more convenient for the interior decoration of the premises thanks to its size, and the usual — Great suitable for lining the building outside.

In addition to a wide variety of sizes, the so -called The material of the material has channels for ventilation on the back and a convenient system for connecting the boards during installation.

Log: breeds of wood

The lining is made from both coniferous and deciduous wood.

Pine. This is the most affordable option and the most common. However, such wood does not differ with moisture resistance, so apply her For finishing the balcony or loggia, you can only with a special composition.

Larch. Great varia nt dli am finishing any surfaces. Both indoors and outside. Such a lining is not afraid of dampness, insect attacks, decay, so you will serve mmnogo years.

Ash and oak. Such wood looks respectable, but the price also has the appropriate price. It is better to use such wood for decoration indoors with moderate humidity.

Linden. It tolerates well tall temperatures and high humidity - her No need to additionally treat with chemical solutions. In addition, wood spreads a very pleasant smell in the room.

What is a plastic lining

As it becomes clear from the name, such a lining is made not of natural wood, but from PVC. However, do not confuse her With conventional plastic panels: a significant difference in the profile, size and installation method. The cladding of plastic lining is no different in technology from working with natural wood material.

A plastic lining can have different colors, in that number And the texture, and the color of wood. Advantages her in durability, as well as in the fact that plastic does not need additional processing varnishes and impregnations.

Necessary materials and tools

You must decide in advance what the lining will be: horizontal or vertical.

- vertical cladding will visually make the ceiling higher, however By volume Your balcony will be visually smaller;

- horizontal cladding visually expands the space, however And the ceiling seems lower .

The lining is attached to the frame ( crate), for the manufacture of which the guides are needed. It can be, for example, long rails with a rectangular cross section. First of all, take measurements and draw a diagram. Guides are attached to the wall at a distance of 50 —70 cm from each other perpendicular to the direction of installation of the lining.

You need to calculate the necessary footage of the rail:

- Calculate Perim tR St.o her balcony.

- Multiply it by the required number of guides.

- Add the perimeters of all windows and doors to the resulting number (if calculation conducted for walls).

- The resulting figure is the meter of the guides you need.

Next It's time decide With the number of dowels (they are attached to the balcony guide to the wall). There should be at least 80 cm between the mounts.

For burning The required number of lining you need to know the total quadrature of the balcony. Do not forget that the material needs to be purchased 10% more - with taking into account waste and marriage.

When the material is purchased, do not unpack it until the day of installation: let it lie horizontally in the room with constant temperature. Make installation only in dry weather.

For the installation of the lining of the lining with your own hands, you will definitely need:

- drill;

- scurgery;

- lobby;

- knife -haired woman;

- roulette;

- construction level;

- hammer;

- self -tapping screws, d suble and nails .

Preparing a balcony or a loggia for the skin lining

It is necessary to correctly prepare not only the walls, but without fail both the floor and the ceiling.

So, your main task is to prepare the balcony so that subsequently under a wooden lining is not it began development of fungus, which soon finishing material will lead as worthless. Many experts say that impregnations do not always solve the problem of combating a mold, and also the impregnations themselves can give harmful For health man evaporation. More reliable Apply the so -called triple barrier method so that the loggia is not only beautiful, but also safe for households.

Insulation and sealing

In principle, this stage does not differ from preparation for the decoration with other materials: it is necessary to cover cracks, seal the seams, apply waterproofing and lay the insulation coating.

Triple barrier: Stages

- When the work on insulation and sealing is completed, we remove all skirting boards and window sills. The resulting "box" is carefully plastering over the entire surface (to apply putty On the foam-heater, glue the mounting mesh to it with silicone glue). And when the plaster dries, apply px spaklevka PVC. It will provide a durable moisture -proof barrier for walls. Experienced builders claim that wooden decoration even on an open balcony thanks to impregnation putty PVC retains its original appearance up to 5 years. The impregnation itself is very similar to liquid glue PVA. Buy her You can in any construction store for little money. You will need about 20 liters of the composition for a standard size balcony.

- Make a frame, stuffing wooden rails at a distance of 50 —70 cm. Use mounting nails for work. Before installation, process all the rails putty PVC (pay special attention to the ends) and be sure to align about each other - chatter should create a flat surface.

- If you live in a region where it is not very damp, then at the second stage you can stop and proceed directly to the installation of the lining. If the humidity is high - do not neglect the third barrier - MDF (6 mm). In addition, the plates will serve as an additional insulation, which definitely does not place in the northern regions or corner apartments. So, the "box" is simply sheathed with MDF slabs and soaked again putty PVC.

Many masters make a mistake by paving film between layers. Do not forget that polyethylene is not gives breathe wood and development of fungus and mold in such an environment will happen It is more likely.

Installation crate

Installation The frame for the lining is simple. Start with the upper guide if the lining is attached vertically.

- dip the rail of the desired length;

- make it on her marks at a distance of 60 —70 cm - holes for dowels;

- drill holes in the rail (use a wood drill with diameter 6 mm);

- attach the bar to the wall (the upper bar is 10 cm from the ceiling) and put the tags with a pencil on the wall through the holes;

- using a drill, make holes in the wall 5 —6 cm (diameter 6 mm);

- mount the guide using plastic chopiki (dowels are not completely driven with a hammer, more 7 —10 mm is better to wrap screwdriver);

- check the evenness of the guide using the cord;

- do the same procedure with the rest of the rails .

Laginon upholstery by lining

There are only a few simple rules for the execution of the skin.

Horizontal casing:

- you need to start installation from the ceiling;

- the lining is installed with a spike up (this will prevent the grooves and moisture from entering the grooves and how investigation, damage to wood);

- from time to time, the horizontal cladding must be checked using the level;

- the last (lower) bar must be adjusted in size so that it i did not get it to the floor of 10 mm (this gap is subsequently closed with a baseboard);

- the lower bar is attached using nails .

Vertical casing:

- the installation process begins from the corner (choose the angle, which is less convenient to work in order to final — a more complex phase - it was convenient for you);

- the first bar is attached using nails (and groove and crest) moreover, not close to the edge, to Avoid denying wood, but also not far away, to The next rail hid the nail hat;

- the rest of the installation is similar to horizontal casing;

- approaching the opposite corner, we proceed to the insert of the final rail: measure the distance from the groove of the penultimate bar to the opposite wall, by these standards, cut the lining; insert a cut bar into a groove; A gap that will close with a skirting board will remain near the wall .

Installation of the lining occurs equally, regardless of whether the wall or ceiling is facing. Only when everything is ready, you can go to work on the slopes.

The finish processing of the lining

Of course, installation of the lining of the balcony repair more It will not end: wood needs to be covered with protective compositions so that it does not lose its decorative and functional properties for a long time.

More before installation The wood should be treated on the back antiseptic - A transparent primer will interfere with the occurrence of mold and the development of the fungus.

On the front side of the coating lining is applied after the completion of the wall sheathing process. First, clean the coating of dust and dirt - otherwise not a single coating reliable will not stay.

You can process the lining with the following means:

- Water -based varnish. This is a safe composition that will not give toxic fumes or smells and dry quickly. Suitable Such a varnish for glazed Balcon or loggia - where the direct effect of aggressive factors on wood is excluded. Degree of protection such a drug gives low.

- Acrylic varnish. It protects the surface of the tree from moisture and UV rays well. The drug itself is harmless to humans - volatile chemical components in him absent. You can use the coating for both external and internal work. As practice shows, to cover the lining on the balcony, home masters choose this particular means.

- Alciden varnish. The drug is good for use in those regions where the humidity is constantly high. Moreover The drug itself is invisible - external vi d drezesins will not change after processing. Of the shortcomings, it is worth noting a very strong and persistent smell of the drug, and a long period of drying.

- Polyurethane varnish. Designed for external work. Means morozo— And moisture resistant shockproof, however Selects toxic substances that in the room can greatly harm human health.

- Oil paint. This composition impregnates the wood well, however It dries for a very long time. It has a high level of protection.

- Alloken resin -based paint. It is used for external work. Very well protects the tree from low temperatures.

- Morilka. This impregnation is the most common And cheap The method of protecting wood, with which you can also give the coating the desired tone. The stain will protect against the formation of fungus, mold, stop the processes of decay.

- Wax impregnation. Great for regions with increased humidity. Substance creates A strong moisture -repellent layer on the surface of the tree.