Plastic plinths have long been replaced by wooden and almost completely crowded them from the market. These are convenient and functional products that can not only create a neat transition from the floor to the walls or ceiling, but also hide the omnipresent wires and communications. In this article, we will tell in all details how to install plastic plinths and how to choose the best option for your home.

Content

Characteristics of plastic plinth

Plastic plinths are made of polyvinyl chloride mass by extrusion by passing through high pressure molds. The result is a solid and high-strength product with a clear geometry. On many models of the edges are covered with rubber material so that the plinth can fit tightly to the floor and wall. However, in any case, the benefits of using profiles are obvious - you do not need to engage in finishing corners, you get a flat and smooth surface of the desired color and textures, carefully hiding wires and communications.

There are two main types of plastic plinths: for carpet and linoleum. There are also universal options suitable for any kinds of coatings, be it tile, laminate or even parquet. The main difference of carpet plinth is in a special M-shaped form. This is necessary in order to simultaneously press the coating and placing the edge of the carpet. As a result, it seems that the plinth is made of the same material as the floor itself.

There is also a classification of plinths depending on the components in the composition and method of manufacturing, which is a total affects the rigidity:

- Hard - classic solid strips that are installed by the floor or under the ceiling. Have a decorative profile for a typical wooden milling pattern. Such plinths are made of pure polyvinyl chloride, so they have all the qualities inherent in this material: durability, wear resistance, relative flexibility and a wide selection of colors. Hard plinths are most popular, because they are easy to mount and can be hiding wires.

- Soft - similar plinths are a flexible tape made of PVC profile. It is laid out around the perimeter of the room with a one-piece segment, which is much better much better than working with pieces, since the finish is obtained without seams. However, due to low aesthetic indicators, soft plinths are not very popular. Basically, they can be found in administrative and office buildings. Of the advantages you can select a low price, health care, the ability to use indoors with uneven walls. For installation of plastic plinth, polyurethane glue either finish putty.

Since most often for repair in apartments and homes, tough plinths use, we will describe the installation technology for them. But before this it is worth noting that despite the fact that the market shows the widest range of models of various colors and textures, it is recommended to choose products from one batch. Otherwise, minor color differences can be observed. You should also know how material was painted: in mass, with a printed pattern or acrylic lamination. These data will help you choose a plinth for any interior. Laminated film profiles are most popular, since they are very plausible to imitate the texture of the tree, but at the same time they are stronger and more durable.

Advantages of PVC products:

- The plausible imitation of natural wood products.

- High strength and wear resistance.

- The acceptable cost of plastic plinths.

- The infertility of rotting and mold.

- Moisture resistance.

- Color is preserved throughout the service life.

- The material is not deformed.

- The ability to carefully hide communication (models with cable channels).

- Simple installation.

- No need to guess how to cut the plastic plinth to dock the corners - there is special fittings for this.

- A variety of textures and colors of plastic plinths allow you to choose an option for any interior.

Technical features

One of the most useful qualities of plastic plinths is to carefully disguise wires and communications, thereby increasing the aesthetics of the interior and protecting the cable from premature wear. Depending on the design features, conventional plinths and profiles with cable channels are distinguished. The latter consist of two main parts: a plastic mounting plank with a cavity, where the wires and a decorative damper are placed, which hides the communications.

The capacity of the plinths with cable channels can be different - from one to a dozen wires. For cases when you need to hide several wires, experts recommend buying a plinth with several channels inside - one on each cable. So you can observe order and additionally protect each wire (if you have a closure and melts insulation on one of them, it will not harm the adjacent wires).

Products without cable channels are presented as one-piece profiles, which cannot be configured any communication. How to attach plastic plinth such a plan will be told a little later.

On the market you can find the so-called averaged model - the product with an assembly plank, in which there is one chute over the entire length. There you can follow the telephone wire or television cable. Such models are usually used in apartments where there are not too many techniques.

Regardless of the design for all rigid PVC profiles, special connecting fittings are provided, designed to facilitate installation and maintenance. Decorative plugs and connecting parts are also capable of masking defects and protesters allowed during operation. All external and internal angles, plugs and connectors should be chosen according to the size of a plastic plinth and its colors.

Review manufacturers

Before proceeding with the description of the installation, I would like to say a few words about how to choose a plastic plinth, or rather, what manufacturer to give preference. The range offered by the market is so diverse that the injecting person remains only to trust sellers consultants.

A brief overview of the most popular PVC manufacturers of plinths presented in the Russian market:

- Cezar is one of the largest manufacturers with more than half a century. In the early 200th, the company received a certificate of conformity of ISO 9001, which once again confirmed the high quality of products. In addition to plastic plinths, CEZAR produces laminate, profiles for tiles, siding and wall panels, profiles for stairs, thresholds, etc. Plastic plinth Caesar is durable wear-resistant finishing materials made with a sense of style and offered at an adequate price.

- Korner is one of the largest manufacturers of polyvinyl chloride finishing materials in Europe. Plastic korner plinths are popular for more than 15 years, and every year an interest increases interest - models with new colors and textures appear. Plastic plinths are in great demand due to noble dark color and plausible imitation of exotic wood.

- Arbiton - a brand brand of the decor manufacturer, which supplies the market with a wide range of products for interior decoration. In addition to plastic plinths, Arbiton releases sex profiles, outdoor isolation and various accessories.

- T.PLAST is the largest Russian manufacturer of finishing materials and electrical products. In addition to plastic plinths, T Plast can be allocated PVC window sills, accessories, finishing corners.

- Dollken Weimar is a large German manufacturer of all kinds of fittings and docking elements for connecting floors and walls. Plastic Dollken plinths are in great demand, despite the high cost.

So, among the enormous variety of manufacturers from all over the world, we allocated several companies that earned a good reputation. When the choice is made, you can talk about how plastic plinths are attached.

Methods of fastening

The installation technology of plastic plinth is mostly depends on the configuration of the selected model, but the nature of the floor cover also plays a significant role. So, if laminate or parquet laminate was laid on the floor, in no case can be attached to the profile - it is necessary to fix it to the wall. Accordingly, the evenness of the walls also has weight in this situation, since the rigid direct plinth gently attach to the surface curve will not be released. Below we consider the methods for fastening the plastic plinth, the choice of which depends on the specific situation.

Clips for fastening

Clipped fasteners are used to install conventional decorative plinths without cable channels. They allow you to gently fix the bar without disturbing its decorative surface with self-draws, nails or other outer fasteners. The clips themselves and the rear side of the plinth are designed so that after mounting the mounting to the wall you can just fix the whip on the clips. If the profile is installed in this way, you can easily disassemble at any time. However, in the secondary installation of the panel, it is rarely possible to avoid defects, since the attachments and groovers of the planks are very unreliable and quickly come into disrepair. So, since the fixing elements are loosened, the clip is recommended to be applied only if the floor and walls in the room are perfectly smooth.

How to fix plastic plinth on clips:

- Make marking throughout the perimeter of the room, applying a profile to the wall.

- Recover, at what distance from the floor surface clips will be recorded.

- The starting mounting hole must be located at least 10 cm from the corner, the remaining holes must go with a step at 20-50 cm.

- The depth of drilling should be at least 3 cm.

- Clean the surface from dust and insert plastic dowels into the holes.

- Secure the clips with the help of self-tapping screws, then start to wear a plinth on them, ranging from the corner.

Liquid nails for fastening

The adhesive method of attaching plastic plinths is the easiest, because it does not require the use of special equipment. Anyone will cope with such work, but before you decide, you should know about one drawback - it will be very difficult to dismantle the glued plinth, and it will not work again. It goes without saying that this method is not suitable for products with cable channels, since the service of communications is further becoming difficult.

So, to fix the plinth, it is necessary to try it on the place, trim in accordance with the geometry of the room, apply liquid nails to the back side and gently press the place. How and what to cut plastic plinths you will learn in the next chapter.

Classic fastening of screws

The last method is the most reliable, but at the same time the most time consuming compared to those described above. It is suitable for the most sought-after models with cable channels and removable decorative plugs.

How to mount a plastic plinth:

- Attach the profile to the wall and a simple pencil note the drilling points of the holes under the fasteners. They must be located no less than 50 cm from each other. The installation step depends on the width of the plinth and the material from which the walls are made. For wood, foam blocks and drywall, the installation step must be 20-30 cm, for bricks and concrete it can be increased to 40-50 cm.

- Drill holes for plastic dowels and drive them with a hammer.

- Remove dust and attach the score bar to the installation site. Marker or pencil mark on it the installation points of fasteners. This method may seem long, but you will be sure that the holes on the bar coincide with the dowels in the wall.

- Start setting the bar from the corner. On the end, put on the corner element, attach a whip and secure it with self-draws.

- Put on the docking element on another end.

- Measure the following bar, disconnect when necessary and put in place.

- After processing the entire perimeter, put decorative plugs to ends on both sides of the doorway.

- If you work in a spacious room, lay the cable inside the plinth gradually, along the installation of the planks. If the room is small, you can first fully set the profile, and then stretch the cable in it.

- After laying the communications, the upper decorative bar.

Useful advice: In order for the plinth easily to get into place and did not rest in the partition of the auxiliary parts, during measurements, subtract 2-3 mm of length on each side.

Below on video shows how to properly install plastic plinths with cable channels:

How to cut plastic plinth

The installation of PVC plinths is inevitably associated with their sharp to form neat angles or linear connections on long walls. Since the polyvinyl chloride panels are distinguished by the hollow and flexible structure, the traditional way of cutting to them is not applicable - an uneven edge and chipped for wood for wood. From how correctly the plinth is cut, the final result of your work depends. Some errors and defects will help disguise the plugs and connecting accessories, but the instructions are not necessary to neglect the instructions.

A decisive role plays a choice of tool - how to cut a plastic plinth? From this depends the accuracy of the edge of the saw. The optimal option, according to experts, is the metal hacksaw, since, unlike a saw saw, it is equipped with small teeth and a divorce allowable width. But at the same time, its use is limited to the stiffness of the panels - it cannot be used for thin-walled products, as they are too sensitive and can be torn under the teeth of the saw.

Handmade jigsik is the most gentle tool, and if you doubt what to cut the plastic plinth of a small thickness, it is better to use it. It leaves the perfectly smooth slice and is suitable not only for outdoor, but also for ceiling products. The only minus - the small cannol will not work quickly, and the stub is appropriate not always.

Important: For cutting plastic plinths, use the canvas for manual jigsaw with teeth, but not round caps with an abrasive coating.

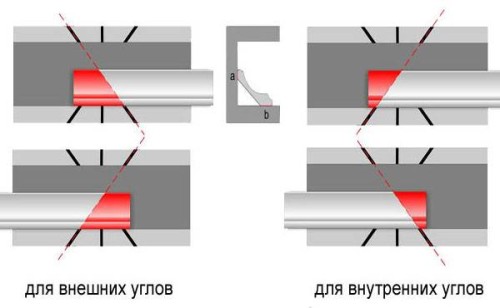

If you work with very thin plinths, try cutting them with an ordinary stationery or construction modification with an enhanced blade. True, to get a smooth cut, it is better to practice on unnecessary segments. The main rule of correct trimming is the observance of clear geometry. Otherwise, you will not achieve a neat connective seam between two panels. It is almost impossible to make a similar procedure "on the eye", the more newcomer, so it is better to immediately leave this idea. It was for this that the stuslo was invented - a special tool that allows you to cut the profiles at an angles of 45 ° and 90 °.

How to crop the angle of plastic plinth with a stouch:

- Place the plinth in the tray located in the center of Stusla.

- Attach the panel to the black surface tool so that in the process of the cutting does not damage the decorative face.

- When choosing the necessary angle of the cut, make sure that the edge of the profile played the edge of the guide diagonal slot of the stouch is quite a bit. So the panel will be securely fixed, and you will get the perfect cut across the entire width.

- If the width of the plinth is less than the depth of the stub, evenly press the panel to one of the sides of the groove, then make the cut. In no case do not place the profile in the tray at different angles, otherwise, in the end, you will get inadential shapes.

- Insert the lobby cloth or other cutting tool into diagonal slots and evenly saw the panel. Do not press on the saw, otherwise the elastic structure of the PVC profile can crack. Also, it is not necessary too hurry - the rapid movements will warm up the metal blade, which will lead to the deformation of the edge of the heap.

- After cutting one hand, proceed to the formation of the second, acting on the same scenario, as before, only with the mirror opposite of the angle. To "fill" the corner of the cut, place the profile in the stouch on the other side.

- How to cut plastic plinth directly? To obtain a straight cut, use perpendicular guides. During the cutting process, constantly monitor the panel to be in the tray uniformly.

Will summarize the above-mentioned video information how to cut plastic plinth and how to handle stupid: