In the process of finishing the room, drywall is a rather popular material, which without special costs will allow you to level the surface and construct any shape of the ceiling or wall. Installation of drywall involves the installation of the profile and its fixing on it. How to fix the profile for drywall we consider further.

Content

Options for installing drywall

There are three methods for attaching drywall to the wall. The first and most common is the fastening of drywall to the profile. The second is the gluing of the drywall leaf directly onto the wall. And the third is the installation of drywall on a wooden structure.

The option of gluing the drywall sheet is the easiest, but requires the presence of a perfectly leveled wall. The adhesive solution is applied to the surface of the drywall and on the wall. The sheet is applied to the wall and is aligned using the building level. This glue has the property of quick drying, so the work is carried out very quickly.

Installation of drywall on a wooden structure is a little more complicated and requires the installation of horizontal and vertical guides made of wood. They are fixed on the wall with self -tapping screws. There is an option to install only vertical bars, but, in most cases, horizontal jumpers are mounted every 60 cm.

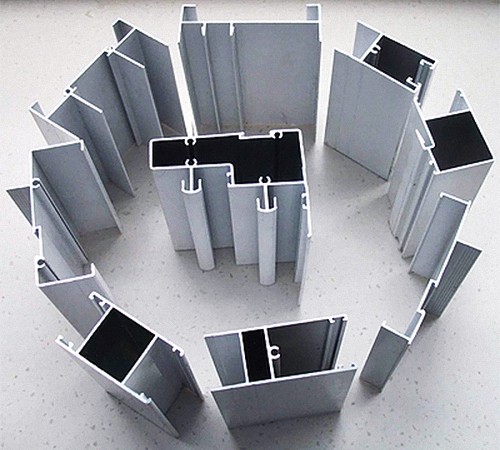

Features and varieties of profile for drywall

To fix drywall, a galvanized profile is used. Its main function is the fixation of drywall on the surface of the wall or ceiling. The profile allows you to build structures of any shape and size.

When performing these work, you will need the use of profiles of various types and purpose, as well as a large number of connecting elements.

Advantages of using the profile when installing drywall:

- the possibility of creating curly structures;

- all communications are laid under drywall, such as wiring, ventilation system, water supply, etc.;

- there is the possibility of forming a heat and soundproof layer between drywall and a wall.

We offer to consider the main types of profiles used in the process of installing plasterboard structures. In accordance with the purpose, the profiles are divided into:

- specialized, with which certain planes are sheathed;

- profiles for the construction of partitions.

The first option is used in the process of skin or ceiling. To create structures of this type, use three types of profiles:

- UD profile;

- CD profile;

- arched profiles.

All profiles have a standard size, the main difference between them is in the size of the metal and its length.

To decide what profile for drywall is needed, we propose to consider the main types of profiles in more detail:

- The profile for fixing the drywall UD is used in the process of building flat surfaces. For example, if it is necessary to form a frame of drywall, then this type of profile will be installed along its perimeter. The dimensions of this profile: width - 2.5 cm, length - 300 cm. The UD profile is characterized by a high level of reliability due to the thickness of the metal that is used in its manufacture. It is the durability of the structure that is built depends on the thickness of the metal. This profile can be of different thicknesses: the thinner is used in the construction of the walls, and the thicker - when lining the ceiling structures.

- The CD profile is also called the bearing, since its use is associated with the formation of metal frames and the effect of the main load on the drywall structure. Gypsum cardboard is fixed on this profile, and it depends on how tough and strong this design will be. CD profiles are of various thicknesses. Profiles with a minimum thickness are less reliable, therefore, in the process of installation, they require a large number of fasteners. The width of this profile is 6 cm, the thickness is 2.5 cm, and the length is 3 or 4 m.

- The arched type profile is also a guide or supporting profile, which is characterized by a large number of incisions that weaken its structure. If necessary, such a profile is easily bent and takes any shape.

The second group of profiles is partition. They are used for lining of flat surfaces. Such profiles differ in large size and other functional purpose. They are produced in various sizes. In accordance with the width, the profiles are: 5 cm, 7.5 cm, 10 cm, 12.5 cm, 15 cm. The width of the profile depends on the technical features of the partition on which it is installed: sound insulation, thermal insulation, communication work.

- UW guide profiles are used to build a flat surface and direction of the partition. Their installation is carried out throughout the area of \u200b\u200bthe partition.

- The rack CW profiles enhance the frame and give it greater strength. Strengthening occurs after 40 cm, so that the sheets of drywall are attached on both sides.

Fasteners and fixators for the frame from the profile for drywall

To fix the profiles, different fasteners are used, which also interconnect various types of profiles.

Consider the most popular fasteners used in the construction of drywall structures:

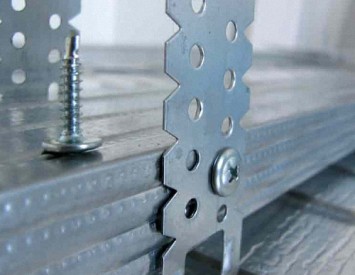

- P-shaped brackets-this fastener is a perforated steel plate that can bend into the form of the letter “P”. Its main function is the connection of the wall or ceiling with a steel profile frame. The middle part of the bracket is fixed on the sheathed area, and the final areas are attached to the supporting profile using self -tapping screws.

- Quickly suspension-are an alternative replacement for the P-shaped bracket. In the case when the length of the P-shaped bracket is too small, the fast-suspension is used. Its main components are: knitting needles, at the end of which there are ears and a suspension directly, which is fixed in the CD profile. The connection of the knitting needle and suspension occurs using a special spring mechanism. The advantage of this mechanism is the ability to adjust the horizontal position of the profile. The deficiency of the spring consists in its gradual weakening, which leads to sagging the ceiling structure. The use of fast suspension applies only to ceiling structures, because, as a rule, the length of the P-shaped bracket is enough to fix the profile on the surface of the wall.

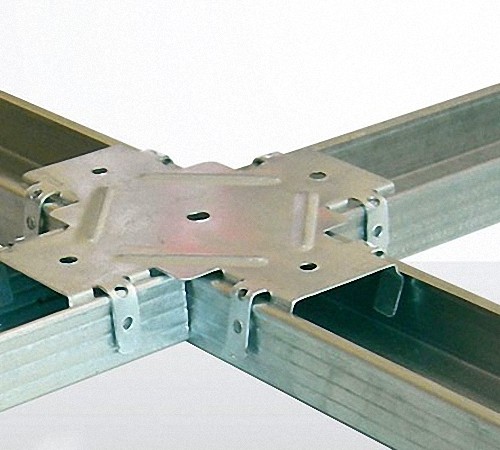

- CDs CDs are used during the installation of jumpers that connect the main profiles of the supporting type. The connection occurs crosswise. The CD-type CD-type CD is mounted on a profile surface and snap on it, and then attached by self-tapping screws or special antennae. The installation of a jumper also occurs: first it needs to be clung to crab connectors, which are located on a supporting profile located in the neighborhood, and then fixed with a self -tapping screw. To install such a product, the presence of eight screws is necessary.

- CD connectors perform the extension function of the supporting profile. One part is installed at the end of one profile, and the second is put on the profile. Then they are fixed on both sides with four self -tapping screws.

- Two-level CD-type CDs are very rarely used in working with profiles. They are used in the installation of a frame structure, which is attached to a wooden floor. The frame that is assembled using the data of the connectors is double. First, the first level is formed from the CD profile, which is fixed on the surface of the wall and build a movable structure from it. Then the second level is mounted, which is connected to the first using a CD-connector. This design helps to improve the strength of the drywall structure in a wooden house, and repels a change in the size of the tree during its operation.

Profile fastening methods for drywall

Materials necessary for work:

- plumb line - 2 pcs.;

- nails;

- chalk;

- level;

- hammer;

- rope.

Attach plumb line to the upper part of the wall, which is located under the ceiling. Instead of a rope, it is better to use a fishing line, three parts of which are pulled along the plumb line to get a perfectly even surface. The highest point between the plumb line and the wall is the guide on which the profile will be attached.

Using a chalk and an additionally stretched fishing line, make a breakdown according to a pre -designed design. Using the rule and chalk, draw the perimeter.

Before proceeding with the direct fastening of the profile, it is necessary to carry out work on its preliminary strengthening. This will require the presence:

- punch with a drill nozzle;

- hammer;

- dowel-grooves;

- pliers;

- scissors for metal.

- Start working from the bottom - it will be more convenient to fix the profile. Attach the profile on a pre -drawn surface, retreat from the lower edge of 300 mm, and drill a hole for its fixation.

- Make two more holes in the middle and lower part. Check the correct attraction of the profile and its compliance with the drawings, then clog the nails.

- Measure the distance that remains to the height, and add two centimeters to it, install the overlap guides. Using the scissors for metal, make a segment of the side parts, bend the profile out and cut the middle. Slobes will help in aligning the edges.

- Now install the guide profiles for drywall, in the docking areas, fix it using a dowel-clamp. Having done these operations around the perimeter, you will receive a profile frame.

- In accordance with the strength of the wall, secure the structure with screws on metal, taking a step from 20 to 40 cm.

To install a vertical profile, the presence of:

- screwdriver;

- metal screws;

- fishing lines;

- rules;

- suspensions;

- perfodrel;

- dowels-gearboxes;

- hammer;

- chalk;

- pencil;

- plakhobs.

Instructions for installing a vertical profile:

- Measure from the wall the width of the drywall sheet and put the mark in this place. It will correspond to the transverse middle part of the profile.

- In this way, it should be noted all the vertical parts that fall for the joints of the sheets.

- Divide the width of the drywall sheet into several parts, the maximum width of which should be half a meter. Put the mark on the floor.

- Now, using a plumb line installed on the ceiling, transfer this mark to the surface of the ceiling.

- On the middle part of the wall, the distance between the ceiling and the floor should be measured. Move measurements to the surface of the profile and reduce one centimeter. Cut the side parts of the profile, bend out and cut the middle part. Using pliers, you need to level the cut and bend the edges - this will facilitate the installation of a vertical profile.

- Install the workpiece on the wall surface and outline it on both sides. Divide the wall into three parts and mark.

- Attach the suspensions using a dowel-gvo. They will help to fix the profile and set it in level.

- Install the second suspension and fix the vertical profiles for metal screws.

- On vertical guides you need to attach screws at the level where the suspensions are located.

- The side parts of the suspension need to be bent and set vertical profiles in accordance with the fishing line.

- If errors are found at this stage, it is still possible to fix them. Therefore, carefully check the evenness of the structure.

Installation of horizontal profile for drywall

Horizontal areas are jumpers between vertical parts of the structure from the profile. Their main function is to strengthen the overall structure and increase its rigidity. These parts are not attached to the wall.

For these work, the availability of:

- screwdriver;

- metal screws;

- pliers;

- scissors for metal;

- crab connectors;

- pencil or marker.

At the intersection of a vertical profile with horizontal, crab connectors are used.

Otherwise, you need to perform a number of actions:

- take measurements between two vertical profiles;

- cut the workpiece and try on it;

- using a marker, put the tags so that the profile is placed in the hole between the verticals;

- with the help of scissors for metal, make incisions on the side parts of the profile;

- plafers align them outward;

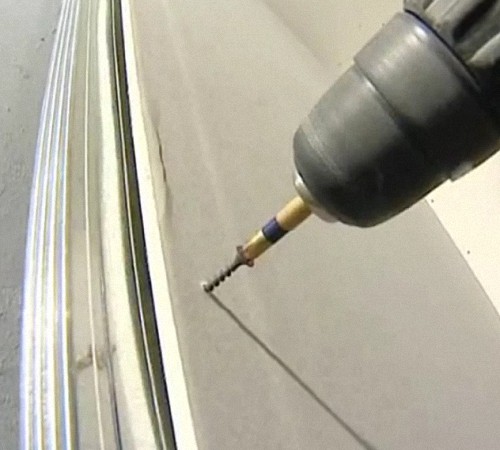

- install the profile and secure it using self -tapping screws;

- check the evenness of the structure.

How to fix drywall to profile

To carry out work, you will need:

- screwdriver;

- self -tapping screws;

- pencil;

- rules;

- stationery knife;

- rubank;

- roulette.

The standard wall requires more than one plasterboard sheet, so consider this installation option.

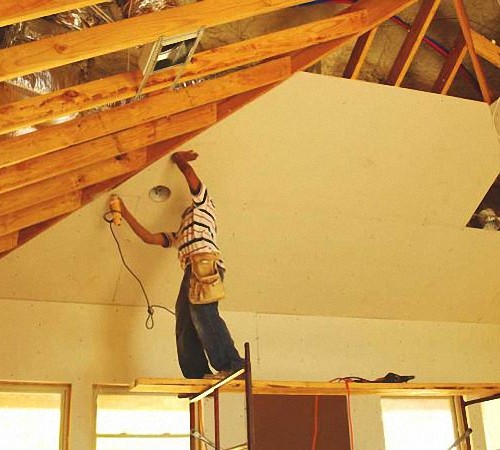

First of all, entire sheets are installed. To do this work, you need at least two people. One of them presses the sheet to the profile frame, and the second fixes it with self -tapping screws. The first sheet is installed from below, and the second on top. This design is more rigid. Then it is required to fill the remaining space.

Using a roulette, make two horizontal and vertical measurements. Transfer them to the drywall surface and mark. Set the rule on the line along which the drywall section will be made. Using a clerical knife, cut a drywall to the middle. Install it in such a way that one part hangs it, and break it on the cut. Then, using a knife, cut the paper from the other side. Using a rubbank, the cutting of the cut. Do the same with the second side. Install cut elements and fix them with self -tapping screws. When all sheets are installed, additionally fix them with self-tapping screws, taking a step of 20-30 cm.