Anchor bolts are one of the main fasteners, without which it is difficult to imagine the construction and repair process. Without these indispensable assistants, the installation of almost all structures is impossible, at the base of which is concrete or brickwork. From the German language, the word “anchor” is translated as “anchor”, and this is not in vain. The very principle of operation of the anchor bolts is built on the fact that, thanks to its design, it, as it were, holds a hinged structure in concrete.

Content

Anchor bolts. Areas of application

The history of the anchor bolt began quite recently. Previously, wooden traffic jams were used as this fastener. From a piece of wood, a cork was cut out with a large diameter than the dimensions of the screw. Then, in concrete, a hole was drilled, with a slightly smaller diameter and clogged a cork into it, into which, in turn, a screw was screwed. Under his action, the cork expanded and did not fall out of the hole, holding the entire structure.

True, such an “anchor” had a lot of shortcomings. Firstly, wood has not quite suitable characteristics for these purposes. Such traffic jams were very often destroyed under the influence of moisture in concrete. In addition, they could not be used to install such heavy structures as a suspended ceiling. Secondly, these traffic jams had to be made manually, which took a lot of time. Imagine more than a hundred pieces of such fasteners to make repairs in one room.

To solve these problems, engineers developed plastic anchors. They were able to remove part of the difficulties that builders faced earlier. Such elements have become more accurate in size, they are easier to mount, and they are less susceptible to the pernicious influence of the external environment. However, they did not become a panacea. The fact is that plastic cannot withstand large loads under which it usually deforms, which leads to the destruction of the structure.

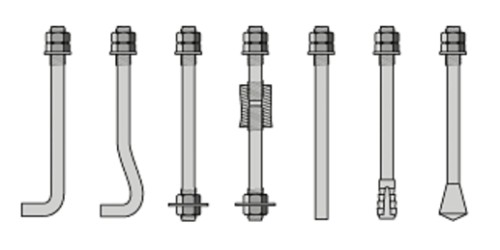

Almost all problems were solved using metal anchor bolts. Thanks to them, it became possible to install rather heavy structures on the walls, such as the brackets of air conditioners, satellite antennas, attach massive metal doors, cable garters, for which an anchor bolt with a hook is used. An anchor bolt with a ring can be perfect for the same purpose. Thanks to various configurations of metal anchors, they are multifunctional and suitable for solving various problems.

In industry, anchor bolts have been used for a long time. If you look at the power line, you can see that its supports are on the concrete foundation, screwed with just such bots. They are exhibited according to drawing data and poured with concrete. Then a metal structure is attached to the anchors. Almost all heavy equipment at large industrial facilities is installed on anchors. The calculation of anchor bolts for such structures is one of the important tasks at the design stage of the object.

Classification of metal anchors

Speaking about the classification of these fasteners, several categories can be distinguished.

Anchor bolts are distinguished by the method of action in two groups:

- Chemical anchors. The method of action of this type of fastener is based on a substance that is enclosed in the capsule inside the dowel. When the employee sets the anchor and begins to tighten it, the capsule with the adhesive is broken, and fills the entire hole. Such anchors are indispensable when there are voids in the walls or in the floor slabs on which they are installed. However, these fasteners have its drawbacks. When installing them, before fixing the structure to them, you need to wait a little time.

- Mechanical questionnaires. They are more common and popular than chemical. The principle of operation of such an anchor is based on the wedging of the metal sleeve, due to the spacer sleeve, which moves along the inner surface of the sleeve along the threads of the hairpin or bolt.

Depending on the design of the anchor bolts, they are divided into several main groups that are different according to the principle of action.

- Wedge. This type of anchor works thanks to the wedge at the end of its sleeve. When it is clogged into the hole, the wedge moves along the inner surface of the sleeve and thereby bursts it, due to which the anchor bolt is strengthened in the hole. In some models of fasteners, the linening of the sleeve occurs due to the installation of a special rod inside, which is subsequently removed, and a special hairpin is placed in its place.

- Clogged. The fasteners of such anchors are due to specially produced edges of the sleeve. These parts of the fasteners are usually made of soft metal and, when clogging, the anchor simply blazes, fixing it in the hole. This simple design of the anchor requires a clear observance of the size of the hole both in length and in diameter. This type of fasteners is used mainly in monolith-concrete or stone.

- Expanding anchor or butterfly. Such fasteners are used mainly in thin -walled materials. This is a through anchor with a special structure of the sleeve, which has slots in the middle. When the anchor screw is twisted, its back moves along the thread, thereby deforming the sleeve. It is revealed, the image of the so -called petals that press the anchor to the inner surface of the plate. These fasteners are used to attach structures to drywall, plastic or fiberboard. The low weight of this type of anchor bolts is perfect for solving very complex problems.

- Expanded Anchor. This type of fasteners is the most popular and popular. Such popularity is based on the fact that they do not require the exact size of the opening depth to install the exact size. The principle of its work is the canovic method of expanding the sleeve due to the movement of a cone -shaped sleeve along it. Such anchors are used in full -length brick or concrete.

The material for the manufacture of anchor bolts are highly alloyed stainless steel, which are additionally covered with an anti -corrosion coating. The internal bolt or stud is made with a metric thread with a diameter of 6 mm to 30 mm. Qualitative indicators for anchors are the standard for a tender force and a slice.

How to install an anchor bolt

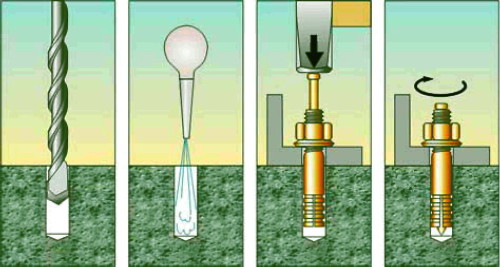

This operation does not require special knowledge or skills, and everyone can correctly establish such fasteners. On the Internet it is possible to find a lot of videos on how to fix an anchor bolt. The algorithm for installing an anchor bolt with a nut is as follows:

- We evaluate the condition of the wall. Quite often, in the houses of the old building, a layer of plaster was applied to the walls, which could not hold the anchor. Therefore, the estimated length of the fastener element must be increased by the thickness of the plaster. That is, if an anchor of 50 mm long is required for the installation of the bracket, and the plaster layer is 20 mm, then the minimum length of the anchor bolts should be 70 mm.

- We select a drill with a diameter of 0.5 mm less or equal to the size of the anchor bolt. It is not recommended to drill too much hole. The fastener sleeve should go into a drilled hole with a slight effort.

- We mark the surface. This must be done as accurately as possible, otherwise after fixing the anchor, it will already be impossible to pull it out.

- The drilling of holes in concrete is performed with a perforator or shock drill with a special carbide tower. It is better to drill a brick without blows so as not to damage its structure.

- The drilled hole must be cleaned of dust with a brush, vacuum cleaner or spray can with compressed air.

- Next, with the light blows of the hammer, we install the anchor sleeve. If this cannot be done, do not hit it hard with a hammer on it, you can ruin everything. Go a drill one time, grunting a drill slightly to destroy the hole.

- Then we screw the spiral of the anchor into the sleeve, and then wrap the nut on it. When the nut reaches the sleeve, clamp it with the key.

Anchor bolts fastening with the "butterflies" of the cornice to the suspended ceiling

If you have a suspended ceiling in your house, then it is better to install a cornice on a special anchor, the so -called “butterfly”. To do this, take the cornice and drill holes in it, with a diameter equal to the dimensions of the dowel screw. Then, along the drilled holes, we make marks on the surface of the ceiling. After that, in the ceiling, pour holes, with a diameter equal to the dimensions of the sleeve.

Install the sleeve in the hole and fix it. One of the structural features of such anchors is hooks at the end of the sleeve, thanks to which it clings to the surface and does not scroll. Then we take the cornice and fix it on the screws. When we scroll through the screws, the sleeve is deformed and revealed, holding the cornice.

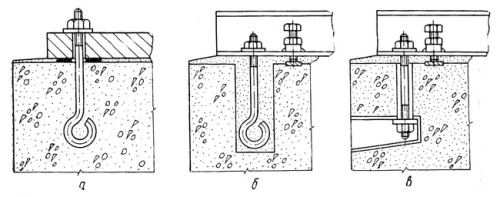

Installation of anchor bolts on the foundation

If you need to install a metal structure on a concrete foundation, then after the basis hardens, drill a hole with a diameter, a little more than the dimensions of the bolt. Then we fill the hole with a special solution and lower the bolt there. After drying the solution, we install the metal structure.