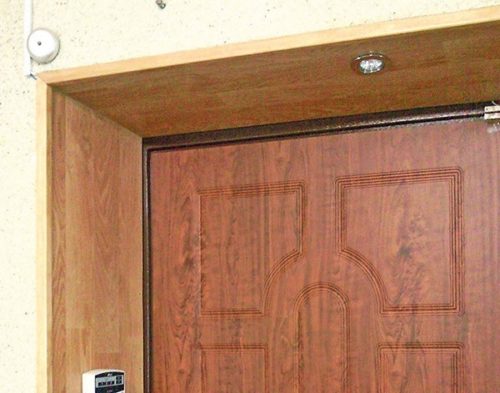

After the replacement of interroom or entrance doors, quite often, before the owners of the apartment, there is a problem of restoring jambs or slopes. It is especially acute for the owners of old housing, where, together with the dismantling of the old door, a decent piece of plaster falls. Restoration of slopes is not a difficult matter, and it can be done with your own hands. Due to the wide range of finishing materials, this problem is quite simple. For the decoration finishing after repair, they do not need special knowledge and great experience. Attentiveness and accuracy will become the key to the success of the operation. About how to separate the shoals of the interroom do it yourself - hereinafter.

Content

How to separate the shoals of drywall doors

The appearance of drywall in the construction materials market significantly changed the repair of the premises. Now it is not necessary to spend a large number of materials and time on the leveling of the walls and the construction of interconnect partitions. Easy in processing and installation, not too high cost - made a plasterboard sheet with one of the most popular finishing materials.

Restoration of slopes with the help of drywall for a novice builder in comparison with work with other materials has a number of advantages:

- Speed \u200b\u200bof work. Even in the absence of experience, such work is done in a couple of hours. At the same time, the slope is quite smooth and looks beautiful.

- Cost of work. The drywall finish costs cheaper finishers with plaster or other materials.

The process of restoring the jacket after replacing the door is performed in the following order:

- Preparation of the surface. The process of surface preparation is starting only when the mounting foam is finally dry. Its remnants are cut with a sharp knife. Also, the remains of the old plaster, insulation and other materials are removed from the surface of the jamb. After that, the entire surface of the discovery is ground to the primer of deep penetration.

- Preparation of plasterboard. To restore the slope using drywall, it is necessary to cut 3 segments of the material: 2 side and 1 top. The height of the side segments should be equal to the height of the slope minus the thickness of the drywall, and the width is the width of the slope. The upper part of the side segments is cut under a small angle, so that the upper segment of its back overlap the corner of the door frame.

- Gypsum gypsum. Plasterboard is glued to a special solution. It is sold in the form of a dry mix and divorced with water. When cooking glue, it is necessary to remember that it dries very quickly. The consistency of the finished solution should be similar to the thickened sour cream. If you do too liquid, you have to keep the panel for a long time until it sticks. The thick solution is too thickly grabbing even before applying to the surface. The glue is applied to the surface of the wall and plasterboard with a spatula. After that, the panel is applied to the surface of the slope and presses. While the solution does not freeze, the position of the panel can be adjusted. Therefore, it is very important to check its correct location by level. Adjustment is made with light tapping hand over the surface of the panel. You need to do it carefully, so as not to leave dents on the plasterboard. First, the side panels are installed, then the upper one. The latter must be maintained so that it does not want to under their weight.

- Surface putty. Since the plasterboard panels do not have too large irregularities, they simply apply a thin layer of finishing putty. Before starting the putty, plasterboard must be projected and let it dry. The putty is carried out with a solution of weak density with a wide spatula. After drying it, all irregularities are wiping with a trowel with a grid with small cells. After the end of the grout, it is necessary to check the surface for the presence of small chosen and not covered places. If any, these sites need to be removed. The fact is that the paint will be shedding badly, leaving dark spots on the surface.

- Sealing ends. External slope angles must be embedded in order to compare it with the wall. This is a simple putty. If the angle turned out uneven, you can use a perforated corner.

- Painting. When the putty process is complete, the surface of the drywall is repaired and painted. For painting it is better to use water-emulsion paint. It is applied using a roller with a long pile. For a good result, it is better to apply the paint with several layers, each of them must be perpendicular to the previous one.

- The last step must close the gaps between the door and panels. It is better to do it with the help of acrylic sealant.

Slopes for doors do it yourself from plaster

This method is quite time-consuming, but at the same time gives excellent results. At the same time, the cost of finishing comes far less due to cheaper materials.

The decoration of slopes of plaster - the process is dirty, therefore, to protect the canvas and the door box, it is better to stick a protective film.

Start work with the installation of beacon profiles. They are needed that the plaster lay on the surface as soon as possible. Installation of profiles is produced on a gypsum solution. It dries quickly, which allows during the time to go to other operations. When placing beacons, it is necessary to check their position in terms of the level and the solution has not yet frozen.

After the beacons are installed, you can start plaster. You can work with the help of a ready-made mixture (will be more expensive) or make a solution yourself. It is prepared from cement and sand in the ratio of 1: 4. Before using sand, it is necessary to sift so that there are no large particles. The solution is thoroughly mixed with a mixer with the addition of water. As a result, a homogeneous mass with a consistency of thick sour cream should be obtained. For better adhesion, the plaster surface can be mixed with water, pre-trunking.

The solution is applied using cells and a trowel. A large number of plaster is applied to the slope, which is stretched by lighthouses. To dry the plaster will be about a day (time depends on the season and humidity). After that, the finish putty is applied to it. Next, the recovery process is practically no different from trimming by plasterboard. The putty rubs, it is ground and painted.

For the same technology, they are finished by the MDF Kosyak panel.

Finishing of slopes for entrance doors with laminate

Laminate is a very beautiful material. Due to the wide range of textures and various colors, the laminate can be selected according to the pattern of doors, making the slope with a part of a single composition. Among the advantages of this finishing material, it can be noted its excellent performance. It does not scratch (of course, the laminate can be scratched, if it is purposeful), it does not require much care, it turns out attractive. During the finishing of slopes, the laminate does not apply dry building mixes, which makes the installation process much cleaner.

However, there are some drawbacks. So, the laminate does not like moisture. Therefore, if the input door is separated, it is necessary to ensure waterproofing. In this case, the life of the laminate will be much larger.

Procedure for work:

- Laminate is mounted on a special frame, which is made of metal profile or wooden plates. After the mounting foam is dry, which constructed the gap between the doorway and the box, is removed using a sharp knife. Then the doorway is cleaned from the remains of plaster and dust. After that, it should be projected. Even if adhesive mixtures will not be used, the primer will definitely prevent. It will prevent further destruction and swollen walls.

- After the primer is dry, you can begin the framework of the frame. Reiki are put perpendicular to the direction of laying laminate. For the slope of the width to 0.5 meters, there are enough two rails for each side. One is installed at the outer corner of the jamb, the second - internal. The mounting of the rails is made on the anchor. Each of them is installed in terms of level. If after that the gap is formed between the rail and the wall, it is filled with mounting foam. After drying the latter, its residues are cleaned with a knife.

- The next step of the laminate is cut into uniform segments and stacked. The laying operation is carried out towards the bottom-up direction. The first segment is attached from below at the level of the future plinth and at the lock level. Fasten laminate with small nails or screws so that they do not interfere with insert the next bar in the lock.

- After fixing the first panel, the second is inserted into the castle first, and is attached to nails. Thus, the entire slope is done. You need to do everything carefully. If the first bar is attached incorrectly, then on the third or fourth deviation will be noticeable.

- At the end of work with the installation of laminated panels, decorative plinths and platbands are mounted. The latter will close the gap between the corner bar. Plugs are attached using small screws or liquid nails.

How to separate the jamb doors plastic

Usually this technique is used after installing plastic window or interroom doors. Then the whole block looks one whole. The process of finishing plastic is practically no different from the installation of the laminate. The only difference is the fastening step of plastic panels. Since the strength plastic is inferior to laminate, it needs to be attached to a smaller step.

Plastic panels, like slopes from MDF for entrance doors, are the most practical finish option. They are not afraid of moisture, it is easy to wash, do not change their freight look. Yes, and their price in comparison with other materials is competitive.

If the surface of the shoals is quite smooth, then the jamb can be separated by self-adhesive wallpaper or decorative film.