For a long time passed the times when the surface of the walls intentionally hid behind furniture. The wall in today's trends in the decoration of the premises often acts as a central figure of the interior, which attracts the main attention. Gypsum panels are a universal tool for creating such a wall-decoration.

To understand how such blocks differ from each other, first we will deal with the qualities and properties of the main raw material.

Gypsum – small -dispersed powder substance of calcium sulfate, which forms crystals in contact with water.

The main characteristics of the gypsum

- Grinding grinding. Gypsum of coarse grinding is used in construction, small - for modeling small decor elements.

- The speed of solidification. To create finishing mixtures, a standard gypsum is suitable, which slowly freezes, for the manufacture of gypsum panels - gypsum, freezing faster than usual.

Classification of gypsum

Depending on the ratio of the volume of dry suspension to the volume of water, such types of gypsum with different density are distinguished

- 1.25: 1 - light;

- 1.75: 1 - normal;

- 2.25: 1 - dense.

It is important to know!

- Average gypsum hardening time: from 6 to 10 minutes. Therefore, do not knead the gypsum mixture “with a margin”, since it will not be possible to use it later.

- The final volume of the gypsum mixture is approximately equal to the sum of the volume of water and dry gypsum powder.

- Do not adjust the already finished mixture that began to harden, adding water or dry gypsum to it. In the opposite case, a defective material with low strength and astringent properties (“dead gypsum”) will be obtained.

Hypsum creation at home

- Highlight the capacity for kneading (the old one, which then is not a pity to throw it away).

- Pour the required amount of water into the container.

- Slowly pour gypsum, constantly stirring the mixture until a homogeneous state.

- Give the mixture to stand a little (before thickening).

- Without delay for later, get to work.

Although, it is much easier to create an original interior using ready -made gypsum panels, which in modern construction stores have a huge choice.

Gypsum wall panels

This quite popular material today is a 60x60 cm plaster modules, which are attached to the even surface of the wall. To do this, the partition is pre -sewn with drywall or simply plastered.

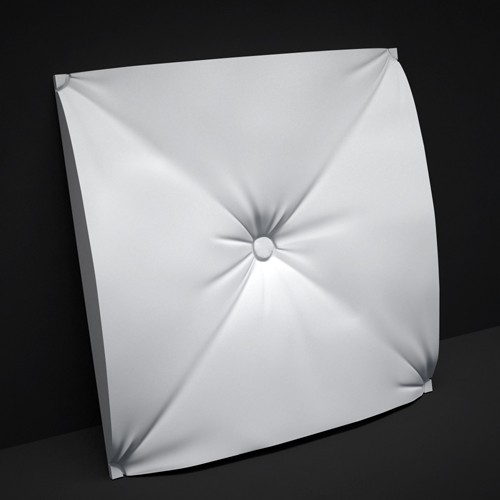

Seamless decorative gypsum panels 3D

The use of volumetric decorative gypsum panels to allow a dull standard wall to make a work of art, a business card and the main art object of the dwelling.

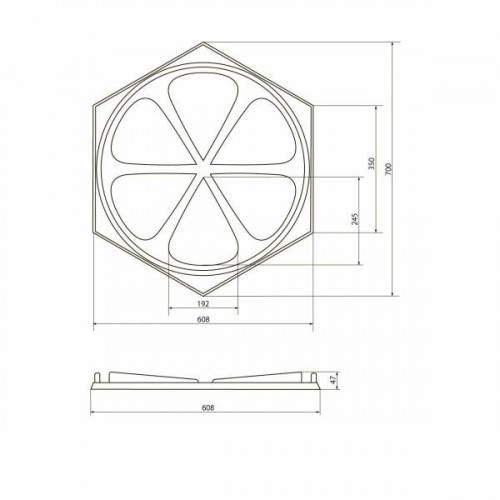

Dimensions of volumetric panels and gypsum

Standard 3D gypsum plates are two sizes:

- 120x80cm;

- 180x60cm.

The thickness can be different in the range from 1.4 cm to 2.5 cm, depending on the relief of the surface. The mass of the design also depends on this: 13-21kg/m 2.

The main quality characteristics of gypsum 3D wall panels

- Environmental friendliness. When heated, toxic substances are not released.

- Long life. These practical panels can be repainted or reduced again.

- Diversity. A wide range of textures, reliefs, sizes - all this contributes to an increase in the number of admirers of gypsum panels among various segments of the population.

- Resistance to temperature differences. Equally well used both in frosty conditions and in hot climate.

- Moisture resistance. The material calmly withstands even prolonged contact with water.

- Heat resistance. They do not burn at all.

- Soundproofing. This property is due to a low density indicator.

- Ease. With a density of about 1000 kg/m3 and dimensions 50x50x2.5 cm, the weight of the gypsum plate does not exceed 5 kg.

- Simplicity of processing. Plates are easily mounted, easily processed with various construction tools and are perfectly combined with any finishing materials.

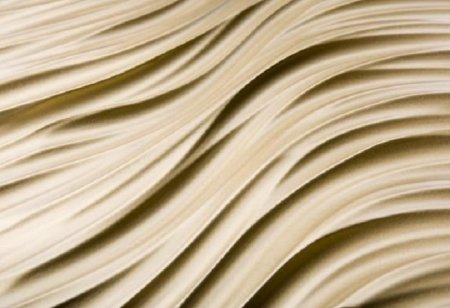

3D panels options

The variety of existing variations of gypsum panels allow you to create a unique modern and elegant interior.

- Large geometric modules with a smooth surface.

- Modules that create a repeated pattern during installation.

- Gypsum panels folding horizontal or vertical ornament.

- Imitation of natural textures (stone, wood, etc.).

- Bas -reliefs.

- Elements that create a voluminous artistic picture during assembly.

- Combined panels (panels with a pattern + single elements).

- Mosaic.

- Custom designs.

In addition, today you can order an exclusive decorative panel from gypsum according to the author's sketch, which will be made on a milling machine with software control or on a 3D printer.

Installation of gypsum panels with your own hands

Necessary materials

- A primer of deep penetration (as for ceramic tiles).

- Level.

- Simple pencil.

- Glue for gypsum (such as Knauf Perlfix).

- Putty for seaming seams (such as Knauf Uniflott).

- Putty for finishing panels (such as Tikkurila Presto).

- Spatula.

- Sandpaper.

- Paint (acrylic, polyurethane or others).

- A brush or a spray for applying paint.

Installation process

- Process the surface of the wall and the working plane of the decorative panel from gypsum with a primer.

- Make vertical and horizontal marking with a pencil using a level.

- Apply glue to the gypsum plate and press it to the wall. Thus, place all the plates.

- Try to make the gaps between the parts of the panel the smallest.

- Switch the seams with putty, removing the excess with a damp sponge.

- Let the joints dry.

- Process the surface of the panels of gypsum with finish putty.

- Let it dry.

- Sub the irregularities with sandpaper.

- Color the wall panel with a brush or spray or process with other finishing material.

The choice of gypsum panels as an element of interior decor is a modern and practical idea that can be realized by yourself. Good luck!