Wooden windows have time -tested history and reputation. It is no secret that they are much preferable to metal -plastic windows. You can not always find a finished window suitable in size and design. It is not difficult to make a wooden wooden window if you have wood processing skills, and you can handle a woodworking tool.

Content

An important point is to choose the right wood. Oak windows are made for centuries, but the oak is expensive and severe in processing material. In addition, there is no guarantee that it was dried using technology. Choose a fought board from any wood species for the manufacture of wooden windows. This guarantees you that the finished window does not twist the moisture and does not crumble. It is desirable that the structure of the board is homogeneous, there are no knots and dark spots.

Preparatory work and manufacturing of a window box

In the window opening, there should be embedded. Mounted, these are wooden bars, fixed around the perimeter of the window. The box is attached to them with long screws and by twisting and weakening of the screws, adjusted in right angles, horizontal and verticals. The number of mortgages depends on the size of the window, but in any case there should be at least three on each side. Before installing a window block, the windowsill must be fixed in its place.

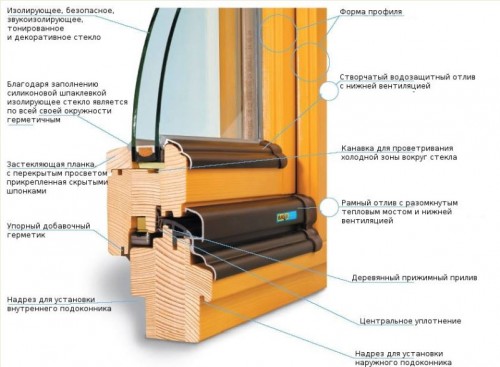

- For the manufacture of a window box, a dry board is suitable, approximately 50x150 mm. In the board, “g” are pulled - figurative grooves on both sides, for the correct adjustment of the frame. In places of fastening of the window loops, a sample is made using a bite or a chisel in size of the ears of the loop.

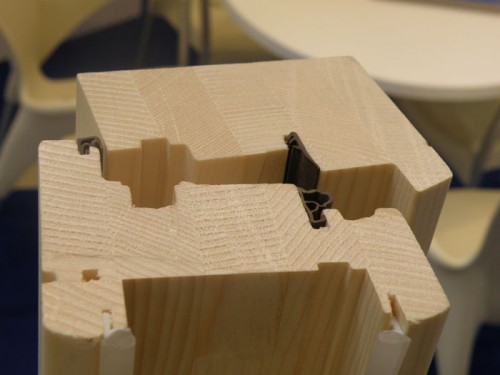

- The connection of the boards of the window box is made on the spike. In horizontal profile boards, a rectangular spike is cut, and in vertical - the size of the spike spike. For rigid fixation of the corners of the box in the end planes, holes are drilled along a cylindrical wooden hairpin, which sits on the carpentry glue. The absolute rigidity of the structure is not worth achieving. A small backlash is eliminated during the installation of a wooden window in a prepared opening.

Making a frame and window bindings made of wood

For a wooden window frame, a well -dried rallied beam of 50x50 mm is quite suitable. The geometry of the profile of the window frame has a complex configuration, and if you do not know what a tear or tide is, then the necessary details can be ordered and protected in the nearest carpentry workshop.

- A simple deaf binding for a frame for three window glasses is the easiest. To do this, you need six bars of the same cross -section. On the bars, markings are made for spikes and eyes. The sample can be made using an electrician, and the profile with an electric rhuban.

- In the middle of the side rails, deaf frames or through eyelets are made. You can make holes with a drill or collar. On the inside, the corner connections of the frame and binding are strengthened by a flat metal corner, and the compounds themselves sit on glue and are fixed with a round wooden hairpin.

- Parts collected in the frame are cleaned by fake or zenzubel. Spikes and eyes should be tightly adjacent to each other. The cracks or cracks formed in the process are covered with putty on wood.

- On vertical bars of the frames and boxes, samples for loop osines are made. To do this, put the frame to the box and make risks at the locations of the loops. The sample is made by a chisel.

- On the lower and medium horizontal rails of the external binding, castings are equipped. Their shape is different, in the form of a square, a rectangular or trapezoid, but there must be a groove under it - a tear. This is a longitudinal sample, at a distance of 1 - 1.5 cm from the extreme edge, 5x5 mm, semicircular or rectangular shape.

- For attaching tide in the bars, a groove is made, and a comb on the frame. Before installing, the ebb is washed down from the side of the near 60 °, and in the wings under 45 °. They plant castings on the carpentry glue and additionally fix with nails.

Arrangement of window binding with a window

It is difficult to overestimate the useful functions of the window. If you are not afraid of the process of making a wooden window with your own hands, then by putting a little effort you can build a window in it.

- In the classic “T”- figurative binding, a vertical profile rail is added. For the window opening inside the room, overhead bars are attached to the previously selected folds, nails or self -tapping screws.

- For the window designed for the outward opening, deeper facks of fastening of the overhead bars are selected. The bait is made either smooth or with surfacing. Safe, strict and sewed after the manufacture of the window. It can be arranged from the side of the narthex, this will prevent the penetration of drafts.

- Most often, the windows are made on single studs, but it is possible on double. The corners are strengthened by flat metal corners. The window can be equipped in any binding, regardless of the profile configuration of the beam. They can be built into a finished and installed window. About how to make a wooden window on its own, the video at the end of the article will show clearly.

Installation of a window block in a prepared opening

Installing wooden windows with your own hands is perhaps the easiest process. The window block with a box is made 3-5 cm less than a window opening. This is done so that it is possible to properly set and adjust the finished window.

- Piss the finished window block with hot natural olifa, two or three times and cover with an antiseptic. On the outer perimeter of the box, secure the band of the rubles or roofing material. You can smash a waterproof sealant.

- For glazing, smear the frame shelves with a transparent waterproof silicone. Grind small cloves with pliers on both sides, in which case such a hairpin will not split the stacking staff. Make the studs on the glazing tapic, also smeared with a thin layer of transparent silicone and carefully beat with light tappings of a small hammer.

- The glazed window block is set in the window opening. With long screws, the block is fixed into wooden embedded and regulated. With the help of a waterpasis and a carpentry corner, a box is exhibited, on all planes. Alternately twisting and releasing the screws, it achieves the perfect state of the box and adjoining the frame.

The space in the opening between the box and the wall is filled with mounting foam. After a couple of hours, the excess foam can be removed, the areas are plastered and decorated with platbands. Then the window can be painted or opened with varnish.