Creating man-made rocks, very similar to natural, is an exciting creative process, used for many years and is economically justified. For the formation of an incredibly realistic scenery with stone boulders, methods of artificial construction of rocks from affordable materials are used. In this way, without special financial investments, while maintaining the cost of materials low, you can create different rocky compositions.

Content

Application of artificial rocks

When creating rocky compositions, artificial boulders often use. These elements of landscape design naturally fit into the surrounding landscape and help to equip the corners of the site to their own taste.

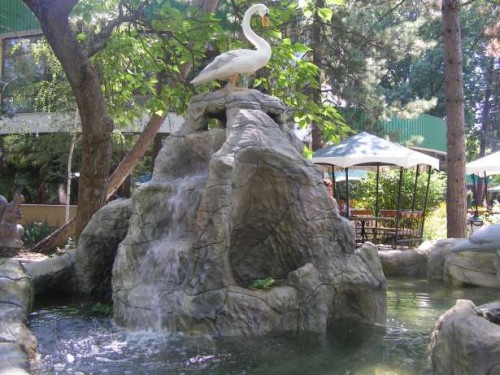

Various types of rocks are traditionally used to create grots, artificial reservoirs, fountains and waterfalls. The cliffs of the shape of the form are used, including for decorating in natural stump-style, wells, as well as for masking located on a plot of pumping and other equipment, hatches, caissons, etc. With the help of artificial, you can diversify vegetation in the garden, flower beds and flower beds.

Advantages of artificial rocks

The advantages of cliffs from artificial stone can be attributed:

- resistance to various atmospheric influences;

- environmental friendliness;

- the ability to create artificial cliffs of any shapes and sizes;

- variety of textures and shades;

- the ability to compile a significant number of landscape compositions.

Compared to a natural stone, artificial rocks differ significantly less costs, as well as a low weight, so that they are easy to move around the site. At the same time, they differ sufficient strength. Artificial cliffs are often very difficult to distinguish from natural limestone, sandstone, slate, dolomite, etc. Such similarities can be achieved thanks to the use of special technologies and the use of various pigments and dyes.

Secrets of creating cliffs from artificial stone

When creating man-made cliffs, it is recommended to take into account some features:

- for a plot of a small area, a large-scale construction of artificial rocks is unlikely to suit - measure the scale, as well as relate the planned man-made design with an existing site landscape design concept. It is recommended to choose a place in advance to accommodate the future design;

- plan also, where you will make the rock with your own hands. For the complete pouring of the concrete, it may be necessary for several days, and then you can place it where you need. For the manufacture of durable design, air temperature will be required at least 16 ° C;

- if you do not have the practice of doing such work, it is recommended to start with the manufacture of a small stone - after some training you can make boulders of arbitrary shape and large size.

To create a cliff from an artificial stone, you will not need special construction skills. It is only required to pre-examine the technology how to make cliffs. In the presence of desire and free time, artificial stone is not very difficult. In addition, such decoration of the site is a fascinating and creative occupation.

Artificial rocks are made without bottom. Having cut a small deepening in the ground and place the construction grid there, place the frame in it and fix it according to it.

How to make an artificial cliff

For the manufacture of artificial cliffs, the following materials and tools may be needed:

- cement;

- sand - It is possible to use it any species - river, career, as well as construction (preferably the use of fine sand);

- construction grid with cells 50x50 or 60x60;

- protective gloves;

- wide scotch or adhesive tape;

- metal trowel;

- nippers or scissors for metal;

- capacity for the preparation of the solution;

- pigment dye for concrete, resistant to ultraviolet rays - in order to avoid quickly burning the color of the rock;

- paint for concrete or polymer stone;

- brush.

In order to make it yourself an artificial rock for the site, you first need to make a frame that will serve as a basis for the manufactured structure.

Sequence of work

As a basis for an artificial cliff, you can use affordable workflows - prepare them in advance. The construction trash, tin cans, pieces of natural stones, as well as pipes, wooden bars and shot down asphalt.

Next, you can proceed directly to the manufacture of rocks from an artificial stone:

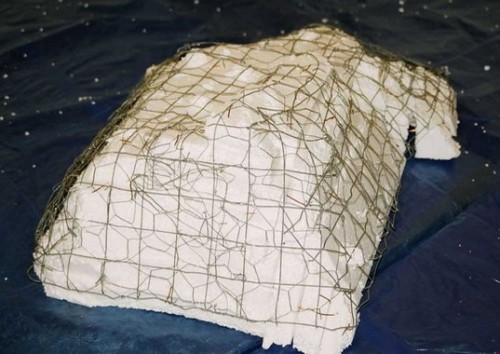

- First you need to form the base from the harvested material, according to the form and size corresponding to the parameters of the future cliff. For a reliable clutch of materials, it is recommended to wrap the frame of the construction grid and fix it with screeds. The base for a large artificial stone can be made of layers from the mounting foam.

- Next, it is necessary to prepare a solution - for this you need to mix 3 parts of the sand and 1 part of high-quality cement, add natural fillers (in their capacity there may be broken glass, stone crumb, broken brick, fiberglass, wood glue, ash, quartz sand). The mixture is diluted with water to the consistency of thick dough, add a pigment dye, if necessary. To simulate a lichen, warm shades of green, dark tones look quite natural.

- The frame is fixed by concrete solution - with the help of a spatula, it is applied to the frame, gradually giving it plastic lines inherent in natural rocks. As a sample, consider how natural stones look like. To give the design of the natural type of stone, it will take some time.

- While the solution is not frozen, you need to give a stone texture. To do this, sand, leaves and small slag can be used to the surface of the artificial cliff. To obtain the effect of a porous structure, use a sponge pressed to the wet concrete. The artisticity of the product will help the grooves, scratches, scratching and erosion applied to its surface.

Finishing artificial rock

The manufactured design is placed in a well-ventilated and shaded place, periodically splashing with water from the spray to avoid drying and cracking its surface.

In addition, it is necessary to perform the final trim of the rock. For this, approximately 3 days after the construction of the structure using fine grained grinding stone, borrowers and unnecessary irregularities should be lost. The surface of the product is wrapped with a painting brush to remove dust, and then need to be washed and dry the cliff.

Next, you can proceed to staining with a brush, filling fine cracks on the surface. Light stone is suitable for decorating dark paint, and vice versa.

In addition, for staining the stone it is convenient to use the sponge - dipping it in the paint, prints are applied to the surface in the form of inclusions. With the same purpose, you can also use the solid roller.

For full frost and further shrinkage, concrete will need some time - on average for about a month. After giving the product of the final species, it is possible to move it to a permanent placement.