Mansard rooms allow the most rational to use living space, therefore, more and more often houses are equipped with rooms in the attic. Like any other dwelling, the attic needs a sufficient stream of light, which will not provide only electric lighting. Therefore, they are equipped with windows that have a certain specificity in the design, due to the distinctive features of the structure of the attic itself.

Content

- Varieties of attic windows

- Handicraft windows design elements

- Attic windows installation scheme, selection of installation location

- Preparation of a place to install attic windows

- Installation and adjustment of the attic window

- Installation of waterproofing around the frame of the attic window

- Installation of the salary of an attic window

Varieties of attic windows

The most popular manufacturers of windows for the attic are Velux, Roto and FAKRO attic windows. The dimensions and design of the windows are selected individually, based on the layout and needs of the attic. Windows are available in various modifications, according to the type of installation, they are divided into:

- Vertical windows are the simplest modification that is practically no different from windows in other rooms. They are mounted in the front of the attic, where the wall is located at a right angle or in a slope. Installation of fax or veluk in a slope at a right angle is installed using an extension of a small additional structure in the form of a house similar to the birdhouse. Such windows allow additionally slightly increasing the area of \u200b\u200bthe room, but at the same time pass a small amount of light.

- Tilted windows. Mounted from one angle with a slope of the roof. This design misses more light and has a variety of opening methods. Not only the classic opening of the horizontal and vertical sash, but also the waist of the wings at 180o and much more.

The next classification shares the attico windows Fakro and Velux according to the features in their design, which also affect the installation process:

- Standard -shaped windows - a square or rectangle. They are the most common, in their design they have a frame and a deaf or opening sash. The most popular are designs with an opening sash, the mansard windows of the veluk or fakro without the function of opening the sash must be ordered separately.

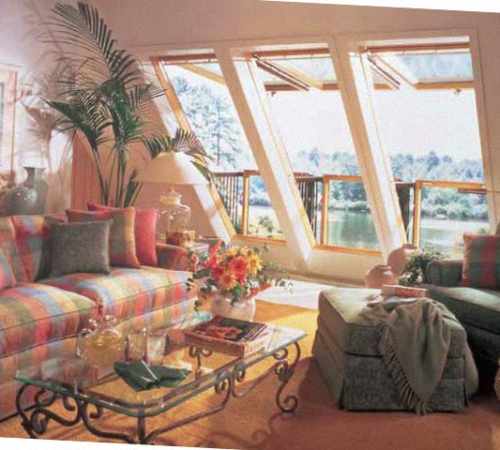

- Windows transforming into the balcony. This design consists of an inclined frame installed in the slope, the second frame is installed on the side or below. One sash opens up, and the second to the side or down, forming a small loggia.

- Additional element at the bottom of the window. The opening sash is equipped with a small dense element from below. Such an addition is used when the size of the slope is not large enough to install two openings, and lighting from one window is not enough for the entire attic.

- Steases in the upper part of the frame. They are made round or triangular. Such a survey decorates the window, makes it like a medieval loophole.

- Cadet window. It is mounted in rooms with a tall outflow, in which the review is limited through an inclined frame. The inclined structure is supplemented by an opening vertical sash.

- Light tunnel. This design is not very common, it is very specific. It is installed in those places where the slope does not have direct contact with the room. The design is a window through which there is a tunnel or pipe with a hole in the place that must be lit. At the end of the tunnel, the plafon dispersing light is installed.

The attic windows take on a much greater effect than ordinary openings in the walls. They are made from special materials that are suitable for operation in these conditions. It has its differences and installation of attic windows. The price of these products also differs from the cost of ordinary double -glazed windows, this is due to their increased strength and design features. For example, a design with a turning sash has a great price than a window with a conventional sash movement. According to the possibilities in the movement of the wings, the windows are divided into:

- With a rotation axis located in the center, which is scrolled at 180 °.

- With a rising turn of rotation, which is revealed 2/3 from the lower edge of the frame.

- With a combined opening axis, which allows you to turn or raise the sash.

- With an axis located on the side, which functions standardly.

- With the axis located below, which moves forward.

- Windows on remote control. It is necessary if they are located in the zone of difficult reach.

Handicraft windows design elements

The attic window systems are a complex structure that withstands significant loads. This design consists of a frame, a sash and accessories, which makes the sash and its fixation. The price of the fakro and attic windows of Veluks is due to these factors, as well as the presence of additional installation elements.

The mansard windows of the veluk and fakro are installed with a complement to the design of a apron of moisture and steam protection, a groove for the removal of water that does not pass the temperature with material, protective salary and internal slopes. These elements complement the installation kit at the request of the ordering person. In general, the windows of the Velux and the FAKRO attic windows differ the price of the installation, depending on the number of installed basic and additional elements. Independent installation of windows significantly smarts the estimate of all work.

Attic windows installation scheme, selection of installation location

Installing attic windows with your own hands begins with the choice of installation location. It is selected according to the following rules:

- The dimensions of the window are selected, starting from the size of the attic and the gap between the rafters. In the manufacture of the opening, it is not recommended to violate the integrity of the rafters, the opening is pierced between them.

- The optimal window area is 10% of the total area of \u200b\u200bthe room. The side edges of the frame are mounted at a distance of 4-6 cm from the rafters. If the gap between the beams does not allow you to install a window of sufficient size, an additional opening is made.

- The height of the installation selects the rolling of the roof. At large corners, the openings are made below, on gentle in the upper part. The arrangement of the handle is also taken into account, if it is attached at the top, the window is installed at a height of 100-110 cm, the lower position of the handle involves the installation of a window at a height of 120-130 cm.

- There is a dependence of the installation of the window on the material of the roof coating, in the ceramic tiles there are no cuts, the window is located above the side of the coatings. In sheet material, the openings are cut at any convenient height.

- Moving methods are selected based on personal preferences and desires.

After determining the installation site and dimensions of the structure, selected areas are marked on the inner wall. To install the FAKRO, Velux or other manufacturer, it is recommended to choose all components from one model line.

Preparation of a place to install attic windows

Consider the installation of the Fakro or Velux attic windows on an already built roof in a room with non -finished walls. In this situation, a waterproofing film is already placed on the inner surface of the wall, a site for installation is marked on it. The left gap from the frame to the rafters is 2-3 cm, the installation is carried out on the lower mounting beam. When marking the lower line, 9 cm are left for roofing materials from the profile, for flat, 4-6 cm are left. 9-15 cm up are left along the upper line of the window. Then they act like this:

- A cut in the waterproofing layer is made on the marks, retreating 20 cm on each side. The abandoned areas are wrapped inside the room, the roof material is removed.

- Retreating from the rafters 2 cm, cut off the grill.

- On the lower line, the mounting beam is fixed, it is selected from 50 mm in thickness. The beam is fixed with an indentation of 8-10 cm from the crate. Check the horizontal of the beam by the construction level.

- The lower edge of the waterproofing material is attached to the beam with a stapler. The upper edges are attached to the upper crate, the side is pulled out.

Installation and adjustment of the attic window

During the installation of the frame, it is necessary to follow the instructions for installing the attic windows of the manufacturer whose products were purchased. The windows of different brands have constructive differences. Some firms make rectangular fixers that are fixed on the rafters, others offer products with coal brackets attached to rafters and a crate. In all brands, the frame of the frame is carried out to the window in various positions. For example, the instructions describes two grooves with the notes V and N to the attic windows, which determine the depth of the frame of the frame. This indicator changes with different types of roofs and salaries. In general, the installation looks like this:

- The sash is removed before the installation, this process is described in detail in the instructions for the window. The salary is also removed, at the initial stage only one frame is mounted.

- The brackets are mounted in the place allotted for this on the frame. Thermal insulation is fastened along the upper part of the window and fixed with a stapler.

- The heat -insulating material is laid out on the mounting beam, crushed it with a frame and fix it.

- The brackets in the lower part are fixed tightly, and the upper ones are not completely, since the frame has yet to be leveled. Mount the sash and check the evenness of its stroke. If there are distortions, adjust the level of the upper mount. The completely fixed window should correspond to the level, the gaps on the sash should not vary. If you do not adjust the window at this stage, then it will be impossible to further correct the skew.

- The installation of attic windows at this stage ends with the puff of all fasteners to the stop. Side fasteners are also installed to the rafters. Side isolation is attached to the window, a heater is laid on the sides.

Installation of waterproofing around the frame of the attic window

The waterproofing apron is attached to the windows of almost all brands, this applies to FARKO and Velux attic windows. Installation of waterproofing material begins after installing the base of the window. If this material was not included in the kit, then it is purchased and made independently. The cost of attic windows in this case will increase a little. The installation process of waterproofing material looks like this:

- A section of the crate is cut along the upper line of the opening, its width is measured in size of the drainage gutter.

- According to the opening, cut a waterproofing film. They put a drainage groove under the film, install it in the lumen between the crate. In this design, the water will drain not on the window, but in the gutter.

- The apron is unpacked, laid out and the location is laid out so that the window and the roof are protected from moisture penetration. The apron is attached with a stapler, the fasteners - the frame, the mounting beam, the rafters, the upper crate. The apron is tucked under the crate, along the upper line it is made under the drainage groove.

- After the fasteners of the apron, the roof at the bottom of the opening is again mounted.

Installation of the salary of an attic window

After laying the apron, the installation technology of attic windows provides for salary fasteners. The process starts in the lower part and then moves up, the algorithm looks like this:

- At the first stage, the lower corrugated apron is laid, then the parts on the sides and top are laid, the latest overlays are installed on the windows.

- In these works, it is necessary to clearly follow the information in the instructions, since each manufacturer has its own distinguishing moments. This also applies to fakro and velux products, the attic windows in some cases are provided using the sealant. For example, the roto windows are equipped with a seal under which you need to start a salary and fix it there. Factro windows have no such addition, the salary is fixed on the frame, it is covered with special elements on top, masking joints and connections.

- The salary is joined and reliably fixed on the frame and crate.

- The lower apron is fixed at the top on the roof.

- Upon completion of the work, a special element is attached to the salary that creates a dense gasket between the window and the roof.

The manufacture of a window opening in the attic is completed, followed by finishing work and equipment of the window with sunscreen. On what materials will be selected for this, it also depends on how much it costs to install a turnkey attic window. When sealing joints, they do not use mounting foam, but purchased specialized sealants. The slopes for the attic window also have their own distinctive features, the lower part of the slope is always installed vertically, and the upper horizontally. This design will provide the optimal movement of the heat flow from heating devices. As a result, condensation will not form on the glass.

Installation of an attic window, video lesson: