In modern dwellings, various heating systems are often found. Recently, the owners are increasingly embedding equipment intended for heating the floor. This allows residents and guests at home to feel comfort and move around the room without shoes.

Content

Such systems are customary to use in large houses, where the owners have all the necessary opportunities for installing equipment. The bad news is that all this is very expensive. Do not forget that, for example, when using infrared warm floor, considerable money for electricity will go. Accordingly, savings are not shining here.

In this material, we will consider the main features of the arrangement of infrared warm floor with our own hands.

Choice in favor of infrared warm floor

Many people have a logical question associated with the feasibility of using this particular type of warm floor. Practice shows that the infrared system is in the best way for laminate or linoleum. We are talking about the power of equipment, as well as the uniform distribution of heat.

It is most important to remember that the power of infrared warm floor should be no more than 150 watts per 1 square. meter. If there is an excess, then the following consequences are possible:

- changes in the color of the coating;

- the lag of the material;

- softening and deformation;

- selection of harmful substances.

Accordingly, if it is already decided to establish an infrared warm floor, specialists should be involved who will conduct calculations related to the power of the system and a specific room.

The warm floor device and the features of the infrared film

The infrared system of the warm floor itself is relatively simple, and often consists of the following layers:

- laminating film;

- copper tire;

- the glue is high -temperature;

- silver tire;

- carbon fiber;

- the main film.

At first glance, it may seem that the infrared film is quite fragile, and it is easy to damage. Partly this information is true, but at the same time it is worth knowing that with mechanical damage a specific area stops working. This suggests that when installing the film, the most important thing is to be careful.

Manufacturers produce infrared film using laminated and polymer coatings, which exclude the likelihood of a fire situation. Some companies indicate that when the production of such products, they take into account the probability of moisture, so even some changes are completely safe for the system. It cannot be ruled out that there is a lot of infrared film on sale, which has a number of disadvantages. Safety in such products is the most important thing, therefore it makes sense to pay and purchase a film from a trusted manufacturer.

If we talk about analogues - other systems associated with the heating floor, then today there are a huge number. The good news is that each owner can choose the most optimal heating system for himself, but the infrared film is the most practical, given its miniature dimensions and ease of installation. However, at the same time it is worth paying attention to other factors. For example, the water heating in some situations is more secure and durability.

Types of linoleum for warm infrared floor

Practice shows that linoleum varieties can play a colossal role, especially when it comes to using warm floor systems. Therefore, you need to pay attention to the following details of the type of material:

- Alcidal. This is a material produced on the basis of fabric. The peculiarity associated with excellent thermal insulation properties is positive. But the bad news consists in the deformations of the material that can occur very quickly.

- Natural. This is most likely the best option. The material is characterized by safety, as well as durability and resistance to external factors.

- Rubber. This linoleum is based on rubber, bitumen and other synthetic components, due to which the material does not tolerate heating, so rubber material for a warm floor is completely unsuitable.

- Nitro -cellulose. This material has a small thickness, as well as moisture resistance. Everything spoils the fact that this linoleum is quickly subjected to fire.

Materials for the installation of infrared warm floor

- The thermal soldier is infrared (this product is measured in square meters, so you need to pre -measure the space).

- Temperature sensors.

- Thermostats.

- Insulation and contact clamps.

- Heat -refracting material.

- Bilateral tape.

- Wiring.

- DVP.

The main stages of work on the installation of infrared warm floor

- First of all, you need to remove the flooring, under which the film will be laid. The surface must be cleaned, as the location of the thermal muffle should be perfect. In advance, you need to determine where the main heating part of the floor will be located, as well as thermal controllers. You may need to align the floor.

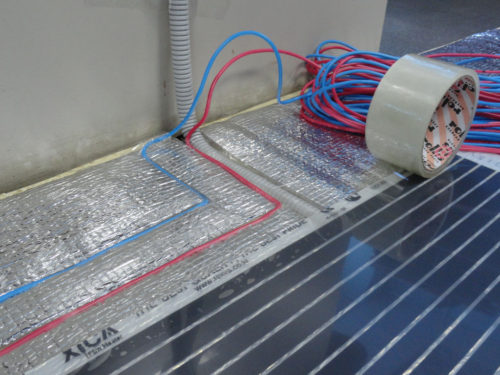

- On the entire surface of the floor, it is necessary to lay the reflective material. Perhaps a good solution would be to use this resource throughout the room so that the heat that is released by floor and other systems does not leave the space. The reflective material is available in the form of paintings, which it is advisable to fasten with tape.

- Next, a thermal clutch occurs. We need several lanes. It is most important to pay attention to the lines along which it is possible to make cutting, otherwise when an error, you can simply bring the system unusable. It is necessary to use stripes as long as possible, which will greatly simplify the process in the future.

- The thermal male is laying on top of the heat -reflecting material with a copper strip down. Contact should be present between the film and the reflector, and any gaps and other disadvantages are unacceptable. For the uniformity of warming up the floor, you need to place the film as tightly as possible.

- The contact clamp is located on a copper strip. The clamp occurs using pliers.

- Places of cuts of a copper tire must be isolated with bitumen. Like a reflective material, the thermal male should be fixed with tape.

- A thermostat is installed on the wall, which should be in an accessible place. Sometimes it makes sense to think about this point, as the role and safety plays here.

- The connecting wires of the installation should be located along the skirting boards along one of the sides of the room. If in some places the wires pass along the wall, they need to be hidden with a special box.

- The bare ends of the wires that go from the floor must be reliably brought to the thermostat. All this needs to be fixed with pliers.

- All connections must be isolated, since security should always be above all.

- Together with the purchased installation, there should be an instruction that should be guided when connecting the wires and the first launch. It is necessary to check the reliability of the mounts, as well as the absence of unreliable connections.

- Near the wall, under the heating film, you need to install a thermostat, which is connected directly to the thermostat. The thermostat itself needs to be connected to the network. Experts recommend this to trust professionals.

- After everything is installed and connected, you need to test the system. This will allow you to understand whether the installation has any critical disadvantages. In addition, there may be errors associated with the connection. All this must be taken into account before using heating fully. If something works wrong, you need to immediately contact specialists, or directly to the equipment manufacturer.

- Immediately after testing, if everything is in order, you can install fiberboard or other floor material. Linoleum is later laid on top of it. In the case of laminate, you can skip a step with the fiberboard.

- Under normal conditions, the system should operate at 27 degrees Celsius, so this temperature is installed on the thermostat, after which the installation is launched. If the installation of the system has passed correctly, then at 27 degrees a comfortable situation will be felt.

Infrared warm floor and safety

Many people do not have much confidence in warm floors, since in this case we are talking about using electricity or other energy resources that can create many problems. Again, this is the fire of floor materials, and the further spread of fire, and excessive heating, which entails burns on the feet. Therefore, you need to remember the following points:

- Install any components of the equipment with the voltage disconnected. Even a slight tension can kill a person and such security must be paid maximum attention.

- Temperature restriction is also available. Experts note that if you set a value above 30 degrees on the thermostat, then there are no problems. First of all, this concerns the possibility of obtaining foot burns. Freation of floor materials cannot be excluded. The acquired linoleum can be persistent to such things, however, when moving over the set frames, the situation may change.

- Testing. Checking the system’s performance should occur only after the integer of the main works. The most important thing is to check the reliability of insulation.

- If you place the thermal ships in 2 layers, then this will create tremendous problems. Overheating, which will begin immediately, will lead to a breakdown of the system.