The quality and durability of the wallpaper glued during the capital or cosmetic repair of wallpaper largely depends on the correct approach to preparing the base. If earlier, before gluing the room with the wallpaper, preliminary pasting of the walls with newspapers was required or wetting with diluted wallpaper glue, today it is enough to make only a priming walls in front of the wallpaper.

Content

The purpose of the primer

The primer is a composition made on the basis of natural or synthetic film -forming elements with the addition of a small number of pigments and fillers.

Compared to newspapers and wallpaper glue, which in the recent past contributed only to an improvement in adhesion between the glued materials, the priming of the walls before gluing the wallpaper performs a number of additional functions:

- strong adhesion of the upper layer of the base, which prevents the cracking and subsequent sowing of the plaster, as a result of which the black wall coating becomes a denser structure;

- alignment of minor hollows, which reduces the risk of the formation of air pockets;

- a decrease in the absorption capacity of the processed surface, as a result of which the wallpaper glue is applied with a uniform layer, thereby contributing to the economy of the adhesive composition;

- the semi -water film excludes the translucent of a concrete or other dark base through thin wallpapers;

- protects the wallpaper from the formation of the fungus, mold, since the film formed after the primer dries prevents the access of condensate directly to the wallpaper;

- cleans the surface of building dust that worsens the quality of gluing materials.

Thus, a primer for walls for wallpaper is a rather significant point in preparing the surface for subsequent finishing work. However, the quality and duration of the trouble -free operation of the wallpaper largely depends on the correspondence of the primer and the processed surface.

The choice of primer

The characteristics of a huge number of soils presented in the modern market are largely determined by the compositions used in the manufacturing process of compositions and elements that affect concrete, metal, a plunged surface, wood coating, etc.

Depending on the degree of influence on the processed surface, the entire variety of primer compositions is divided into:

- strengthening ones - act only a surface layer of the wall without penetration into the structure of the material. When the primer is drying, a film is formed with a thickness of 1-2 mm. Landing of a fortifying nature are ideal for processing wooden, metal surfaces;

- deep penetration - affect not only the surface of the base, but also on the structure of the processed material. Deep penetration primers contain binders 10 times smaller than strengthening compounds, allowing the mixtures to penetrate into deeper layers of the processed material, reaching thickness of 1 cm. Most often used in the priming of faded surfaces, concrete and other materials prone to destroying and crumbling .

Based on the main component, the primers are divided into alkyd, mineral, acrylic, perchlorvinyl, glyftal and many others. However, when carrying out finishing work, indoors are more suitable:

1. Acrylic compositions are used for priming any coatings. The exception is only metal surfaces, since rust over time still seeps through the protective film, since acrylic primer rarely contain anti-corrosion additives. The predominant features of acrylic primers are:

- lack of specific smell;

- ease of cleansing the tools used in the priming under a stream of warm water;

- the speed of drying of one layer takes 1-4 hours.

However, the water-dispersion base of acrylic primers reduces the resistance of the film coating to the negative effects of the environment, therefore suitable for work at a temperature above + 10 ° C.

2. Alkyd compounds are made on an organic basis and contain anti -corrosion elements, therefore, they are used for processing metal and wooden coatings. Strengthening primers on an alkyd basis are highly resistant to various kinds of pollution, as well as good indicators of atmosphere resistance, which allows them to be used when priming the walls of the veranda, summer kitchen. However, the presence of a specific smell is necessary to ventilate the premises during the work period until the composition is completely dry. Unlike acrylic, alkyd primers dry for a day. In addition, the tools after the end will have to be thrown away, since it is unlikely that they can be washed completely.

Thus, when choosing a primer, it is worth considering the level of humidity in the room, as well as the material on which the primer is applied. In most cases, the best option for wallpaper is the acrylic composition of a deep penetration.

Surface preparation

Before applying a primer to the walls, it is necessary to prepare the surface as follows:

- get rid of the remains of glue, wallpaper on the wall by means of a spatula and water;

- remove mold from the walls if it is available by applying a chlorine solution, followed by washing the treated area with warm water;

- peel the wall from peeling pieces of putty with a spatula, clean the rust on metal with sandpaper paper, remove burrs and roughness from wooden coatings;

- a brush moistened in the acquired primer, moisturize defective places and packed;

- check the degree of drying of the plowed places by means of a piece of cellophane in size 15x15 cm on the wall. For this, in the evening, cellophane is glued to the wall with tape from all sides. If in the morning there is no condensate under polyethylene, then the putty has completely dried up and you can proceed to the primer of the walls (watch the video at the end of the article).

The process of applying the primer

Before proceeding with the direct priming of the walls, it is advisable to protect any open areas of the skin, since the elements included in the primer can cause an allergic reaction.

The primer of the walls before gluing should start at least in a day so that each layer, and there should be at least 2 of them, manage to dry well.

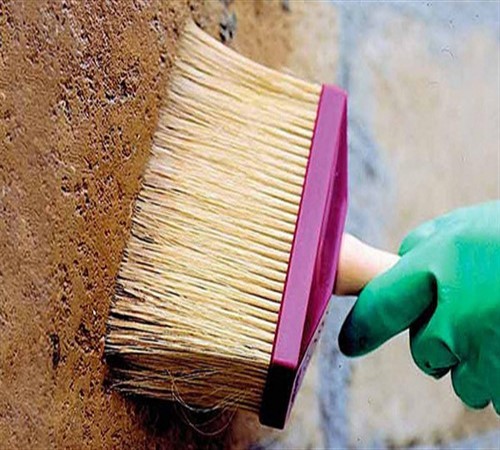

The primer is applied to the prepared surface using a foam roller or spray, and in hard -to -reach places - through a wide brush.

The work is carried out in the following order:

- moisten the places of eliminated shortcomings;

- after drying, the primer is applied with an uniform layer on the entire surface, not forgetting to process all the corners;

- the next layer of primer is applied similarly to the first after 3-4 hours.

After completely drying out all layers of the applied primer, you can breed glue and proceed to the finish walls of the walls with wallpaper.

Thus, if the primer composition is correctly selected and the primer of the walls is carried out correctly - the wallpaper is unlikely to peel off.