While working with an industrial tool that requires high pressure, you can not do without the use of hydraulic oil station. We will talk about the device, advantages and features of the manufacture of oil station with our own hands.

Content

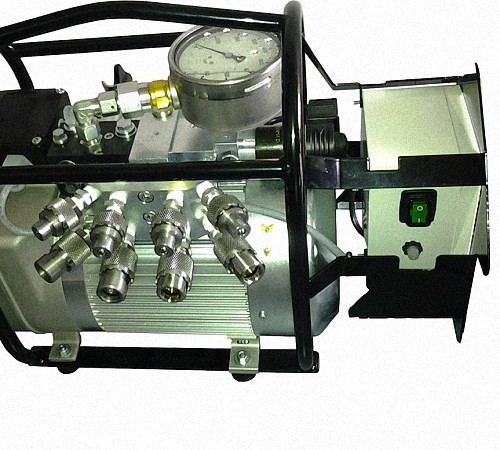

Hydraulic oil station device

The oil station is used to convert various types of energy into mechanical type fluid energy. The hydraulic oil station pumps a hydraulic fluid and creates pressure in the working area of \u200b\u200bthe actuators.

Hydraulic oil station is characterized by the presence:

- Hydraulic tank - it is made of black steel or stainless steel. The inner surface of the tank passes sandblasting and double coverage by polymer. If prolonged operation of the oil station is supposed, then partitions are placed inside the tank, which contribute to mixing and cooling of the liquid. The main functions of the hydraulic tank are:

- fulfillment of the role of the tank in which the oil is located;

- cooling of the working fluid;

- the function of a rough filter in which pollution is defended;

- separation from the liquid of water and oxygen;

- delivery of working fluid for pumping equipment.

- Pump. Pumps come in different types and differ in technical features. The speed of fluid supply by the pump is from 3 to 300 liters per minute. Here are varieties of pumps that are used in hydraulic oil stations:

- gear type;

- plate type;

- radial-plowed type;

- axial piston type.

- Primary engine - in this case, hydraulic. Its main function is the transformation of mechanical energy due to rotation or kinetic energy.

- Pipeline, which is a system of channels consisting of high pressure sleeves. The pipeline also includes metal pipes, which are characterized by a modular or butt installation. Their main function is to combine hydraulic equipment with regulators, energy distributors. Is responsible for the transfer of the working fluid and its timely return.

- Drain filter - it is responsible for cleaning the working fluid returning to the hydraulic tank device.

- The suction filter, which ensures the prevention of the hollow parts of the mechanical impurity into the pumping line. This filter is installed directly at the pipe section under the working fluid. Since the pump has limited suction capabilities, the resistance of filters on the way to the working fluid should be minimal. These filters produce gross liquid cleaning and consist of several structural parts. Some filters have a check valve or a magnetic capture.

- The flood neck in which the air filter is located - this element performs the function of preventing dirt from getting into the working fluid while opening the tank.

- Measuring elements: manometer, indicator of the amount of oil.

- Distributors that are:

- electro -hydraulic;

- manual, with one or more sections.

The principle of operation of hydraulic oil station

A hydraulic oil station is also called a hydraulic drive, hydraulic unit or a hydraulic pumping station. It appears in the form of a system that converts energy through control of hydraulic fluid.

The type of transforming energy directly depends on the design features of the primary engine, which is the main element of the oil station.

The principle of operation of the hydraulic oil station is to transmit the rotating moment from the primary source of the mechanical energy (electric motor or internal combustion engine) to the water pump shaft. Using a suction filter, the working fluid is absorbed, in this case, oil, using a hydraulic pump. Then RSH is transmitted through the pipeline system to hydraulic equipment, which distributes it and determines its pressure on the path to the hydraulic cylinder or hydraulic engine performing the work.

Strived working fluid through the pipes system, passing drain filters, returns to a hydraulic tank.

Advantages and scope of use of hydraulic -type oil station

If we compare the hydraulic oil station with a standard compressor, then it stands out with the following advantages:

- reduction of expenses that go to the transportation of equipment, as well as for installation, maintenance and connection of oil station;

- compact dimensions facilitate the transportation and operation of the device;

- low fuel consumption;

- high performance and efficiency of the device;

- the oil station has a lower noise production than the compressor;

- the device is characterized by a wide scope of use, it is possible to connect the oil station to the units and equipment of various capacities and purpose;

- the simplicity and ease of work on equipment does not require hiring and training of specialists.

The scope of use of hydraulic oil stations is mainly aimed at ensuring the performance of hydraulic devices and tools. With the help of hydraulic oil station, it is possible to launch almost any mechanism. Therefore, they have a fairly wide area of \u200b\u200bapplication.

Hydraulic oil station is capable of working:

- with static hydraulic tools;

- with electrical equipment;

- with a dynamic hydraulic type;

- with construction or railway equipment;

- with sludge pumps;

- with drilling equipment;

- with thermoplastavtomats;

- with presses;

- with systems that are engaged in the rise and movement of large and overall structural objects;

- with test stands;

- with technological equipment.

Hydraulic oil stations are used for pumping and purification of oil. They are able to supply oil in certain parts of machine equipment, make lubrication and cooling its elements. Using hydraulic oil station, hydraulic cylinders, machines, equipment and pipeline systems are tested.

The main areas of the use of hydraulic oil stations:

- industrial;

- metallurgical;

- construction;

- energy;

- agricultural;

- transport.

The main types of hydraulic oil stations

Hydraulic oil stations are divided into several parameters. Depending on the type of movement, they are:

- mobile type;

- stationary type;

- self -propelled type.

The first type is characterized by compact dimensions and is easily transported. Mobile oil stations have low power and are used in the private sphere.

Stationary devices are used in industry. Such oil stations have large dimensions and operate at high power.

Self -propelled hydraulic oil stations connect the advantages of the previous two species. They have both high power and means for transportation, and in particular the wheels.

Depending on the primary engine, the oil station happens:

- hydraulic;

- electric;

- pneumatic;

- gasoline;

- diesel.

The greatest compactness is different oil stations based on a gasoline engine. For the operation of the pneumatic oil station, the mandatory presence of a compressor is required, the minimum working pressure of which is from 0.5 MPa. Hydraulic oil stations based on a pneumatic drive are used in enterprises that make strict requirements for work, and in particular, at factories of the petrochemical or mining direction. Such oil stations have a longer service life and use devices that ensure the lubrication of the system by spraying the working fluid.

Depending on the type of distributors, hydraulic oil stations are:

- With the presence of manual unloading tap - they pump and drop the pressure into the device of the hydraulic cylinder. They are used when working with equipment that has a spring return, such as pipe -beams or nuts.

- The oil station with two -position distributors is pumped up with a pressure that is capable of not only supplies oil for work, but also ensure its return back to the system. Used for equipment that has a two -position effect.

- Devices with the presence of a three -position distributor are the most popular. They allow you to work in the position of the work move - retention and return. They are used for the work of presses.

In accordance with pressure, oil stations are:

- weak pressure - up to 16 MPa;

- average pressure - up to 45 MPa;

- high pressure oil station - up to 155 MPa;

- super -power pressure - more than 155 MPa.

Hydraulic oil stations are distinguished by the control way and happen:

- manual type;

- electromagnetic type;

- automatic type.

In the first form, oil stations are controlled using a handle. The electromagnetic method of control involves pressing the button post, which is located on the oil station, or using the remote control on the buttons.

The third type of management is a combination of the two previous methods. Management is possible with both a remote control and a handle.

Depending on the type of hydraulic drive, oil stations are:

- single -stage;

- two -stage.

Single -stage have a single -flow pump. Such stations allow you to adjust the speed and mode of operation of the hydraulic cylinder. Oil stations of this type are used in cases where it is necessary to make the same efforts to compress the pressed body. For example, in the manufacture of briquettes from waste or garbage. They are also used in the production of dry ice, gluing a wood timber, an extinguishing or pressing.

Two -stage oil stations consist of a two -stage cycle. They differ in the presence of a dual pump and an overcoming hydro -panel. Such stations significantly save electricity.

Recommendations for choosing hydraulic oil station

To buy a hydraulic oil station, you should contact specialized companies or directly to manufacturers.

The price of the oil station depends on the following factors:

- type of primary engine;

- pressure;

- power;

- type of distributor;

- possibility of moving;

- manufacturer.

When choosing an oil station, pay attention to the operating pressure of the drive, the working volume of the piston site, the speed and size of the working course, the type of drive and settings of the hydropower plant.

The main characteristics include:

- value of performance or rated power;

- the size of the tank for the fuel and the value of the pressure of the working fluid.

The determination of the type of oil station in accordance with the management method directly depends on the technical features of the enterprise or the direct functions of the oil station.

Keep in mind that the value of the useful volume of the fuel tank should be a quarter larger than the total working volume of hydraulic equipment, which will be used together with the oil station. At the same time, another function of oil tank is lubrication and cooling, so if it is not more than the required volume, these functions will not be performed.

In order to be able to simultaneously operate several tools, you should purchase a multi -flow crane, port or multidopting pump.

When choosing a hydraulic -type oil station, pay attention to its technical features and first read the operating instructions to determine the recommended supply of the working fluid and compare it with the tool. If the supply is less, then the risk of slow operation of the equipment is possible, in the case of a greater supply, the equipment will fail.

DIY hydraulic oil station

The manufacture of hydraulic oil station is a very complex process. Therefore, in the absence of skills in working with this equipment, it is recommended to entrust this business to professionals.

To make a hydraulic oil station with your own hands, the availability is required:

- primary engine;

- hydraulic tank;

- filters: drain, absorbing;

- pump;

- pipe systems;

- safety valve;

- distributors;

- manometer;

- oil level meter.

Pay special attention to the choice of a hydraulic tank. Its size depends on the type of device that connects to the oil station. It should also be noted that the oil, moving through the system, heats up and returns to the tank heated, and therefore in an increased volume, and requires a place to disperse heat.

Hydraulic fluid absorption zones should have partitions that will improve oil station performance.

Do not use too high viscosity oil if this action could not be avoided - add special additives.

The installation of filters is mandatory - they will extend the operational characteristics of the oil station and prevent its premature breakdown.

There are several ways to attach a hydraulic tank to the design of the oil station:

- horizontal fastening, when hydraulic equipment is attached from above and the engine is located on top of the lid, the hydraulic tank should be hard to prevent engine vibration;

- the lower location of the hydraulic tank - such a design is quite bulky and expensive, improper distribution of pressure requires additional energy to increase cavitation;

- the best option will be the location of the hydraulic tank vertically in relation to the entire station, such equipment is compact and low noise production.

The size of the tank depends on the amount of oil that is required to ensure the performance of the equipment connected to the oil station. Depending on the shape, tanks are cylindrical or rectangular.