Everyone who wants to build their own housing sooner or later faces the choice of roof, while it is durable and does not “hit the wallet”. This can be done by carrying out all the styling work with your own hand. Taking advantage of the correct, and most importantly, technological methods for installing the roof with flexible tiles, there is a high probability of performing work efficiently. When the question arises of choosing one or another type of flexible tile for the roof, it is worth noting that any (even the most expensive and high -quality) gunt will not be able to fully fulfill its function if you do not observe the technology, which will allow it to serve us the most possible time . So what is a roof of flexible tiles, and what difficulties can arise when laying it, we will try to figure it out and not miss a single important point.

Content

Characteristics of the material

The technical component of the roof roof with flexible tiles implies many features and in order to better understand them, we should learn more about this material.

Distinctive features include:

- long service life (up to 40 years);

- cheapness (in comparison with ceramic);

- convenience in transportation (gont is referred to as light roofing materials, weight from 8 to 11 m2).

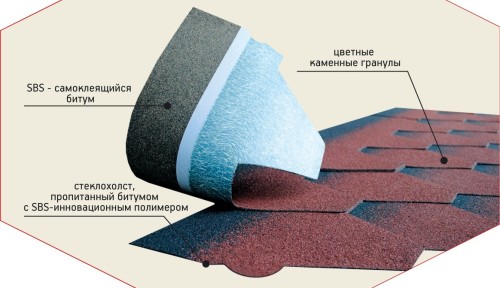

Today, the production process involving flexible tiles occurs in compliance with the latest technologies on modern machines. The composition of the soft tile is based on glasshold, with modified bitumen applied to it on both sides. To protect against weather factors destructive for ultraviolet bitumen, as well as an increase in the life of operation, mineral crumbs in various color variations are applied on the front side of the gunt. More often on the bottom of the plate there is a small layer of self -adhesive bitumen, which is protected by a thin silicone film.

Also, soft tiles are distinguished by several more types of coating (copper and zinc titanium), but the traditional leader still remains a roof of bitumen tiles, which, due to its elasticity, facilitates the design and installation of more rounded roofing projects.

The main components of bitumen tiles or gont:

- The upper (facial) layer is a stone crumb (due to the fact that it is made of a stone specialist, does not crack, has excellent moisture -proof properties, as well as a staining stand at relatively high temperatures, without changing color for a long time).

- The middle layer is a synthetic component (glasshold that gives the plate excellent properties “to bend” and “to break”).

- The lower layer is a modified (or oxidized) bitumen (allows the hound to change in size due to seasonal and climatic differences in temperatures and provides high fire resistance).

Since Gont is attributed to a piece product, this allows him to abandon increased elasticity in favor of roller materials, since he does not form a fully continuous coating of the working surface during the installation. When one or more sheets are deformed, the probability of damage to the whole surface coating is significantly reduced.

Advantages and disadvantages of flexible tiles

Every year, the soft roof is becoming more popular. What is it connected with and what main positive features can be distinguished? What determines the constantly growing popularity of bitumen tiles? Below we will try to figure out all the pros and cons of this roofing material.

The advantages of a bitumen soft tile:

- Protection against the influence of adverse weather conditions (soft bitumen roof has increased resistance to deformations and faults associated with a change in temperature and other weather factors).

- Environmental friendliness - all the main components of the gont contain materials from natural origin, in turn, not affecting the ecology.

- Fire resistance - a sheet of flexible tiles has in its composition the materials resistant to fire, which allows you to protect your roof from fire as much as possible.

- Low weight - allows you to experiment with forms and sizes due to the ease of material, without excessive workload on the rafters.

- Resistance to external damage - when the roof is ready, you can calmly move along it without afraid to be pushed or tore the sheets of bitumen tiles.

- Sound insulation - you will feel comfortable, living under a roof of soft tiles. Due to its excellent noise -absorbing properties, neither rain nor hail to you.

In the market of finishing materials, the bitumen tile has a huge selection of forms and variations of color solutions that can give the home her picturesqueness and originality.

If you still decide to perform the installation of the roof with a flexible tile with your own hands, then our instruction will help you do everything as correctly as possible. But it is worth noting that any, even the highest quality and expensive soft roof, will not last the time allotted for it if the main rules, norms and conditions are not observed. Having understood all the subtleties, we attributed the complexity of installation to its main disadvantages.

Flexible tile installation technology

The correct installation of the roof of flexible tiles is the key to subsequent long -term operation, otherwise sooner or later mistakes will make themselves felt.

The main stages when laying flexible tiles are considered:

- Arrangement of the base for the roof.

- Installation of a layer of lining.

- Assembly and installation of yendov, ends and cornice.

- Laying tiles.

- Installation of junctions.

- Installation of tiles on the building of the building.

Preparation of the base and ventilation

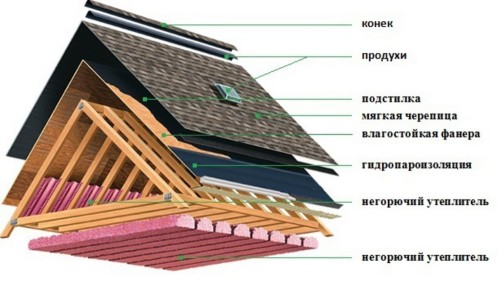

In order to efficiently perform roofing work, you need to approach the preparation of the base with responsibility. It is worth starting with the arrangement of the crate, moreover, it will be a lattice or continuous, you decide. Often for the crate, as well as for the rafter system, wood is used. To do this, usually take strugar boards with a thickness of 2-2.5 cm.

Immediately, we note that for a longer service life of the crate, you should first treat the entire wood with fire protection. This will increase its refractory properties and for many years will repulse any wood insect. For flooring, the crate is usually taken as a moisture -resistant plywood, chipboard, diluted or trimming boards. To compensate for the expansion of wood during the academic, several millimeters should be left between the materials. If the wood was prone to technical drying in advance, then such gaps can be excluded.

When installing a rafter system, it is worth considering that the calculation of the step of the crate, as well as the thickness of the board, must be calculated in advance. For example, for a step of 60 cm, take a board of 20 mm, and with a step of 90 cm - 23 mm, etc.

For ventilation of the roof from flexible tiles, the horse is used, by laying it on a ribbed profile. But often this does not give the necessary results and you have to resort to the installation of additional ventilation elements on the roof.

After the tiles are laid on the slopes, ventilation elements are nailed to it, which are a plastic profile with ribs. They have them every 20-25 cm.

Calculation of flexible tiles

To calculate the number of foures for ventilation, it is worth taking into account the size of the angle of tilt of the roof from flexible tiles. If this is 15-400, then with such parameters the result will be equal to the private area of \u200b\u200bthe roof and 300. For the size of the angle of inclination of 41-850, the area is calculated, dividing the roof area by 600. Suppose, the area of \u200b\u200bthe entire roof is 100 m², the angle of inclination of the roof 380 , and the cross -sectional area of \u200b\u200bthe ventilation element 310 cm².

Thus, the total area of \u200b\u200ball necessary ventilation elements can be calculated as 100/300 \u003d 0.333 m² or 3333 cm².

Therefore, dividing 3333/310 \u003d 11 pcs.

In turn, in order to calculate the number of holes for the ridge, it is enough to divide the amount of their number on the slopes by two, that is, 11/2 \u003d 5 pcs. In the case of the edge of the roof, the calculation is carried out in the same way.

If you have already calculated the quadrature you need and are ready to go directly to the purchase of the material, you should definitely take into account the trimming and waste that will certainly appear during the installation. To do this, it is enough to add the extra 10-15%to the result.

When calculating the material for the gable roof, we need the following parameters:

- length 8 m;

- height 6 m;

- the angle of inclination of the slope is 30 °.

Based on this, the total area of \u200b\u200bthe gable roof will be 8x6x2 \u003d 96 m².

Typically, one Gont Park contains an average of 3 m² (the value can vary depending on the manufacturer; each of them indicates the quadrature), therefore, to calculate the number of packages, it is enough to calculate: 96/3 \u003d 32 packaging.

Lining layer

If you want to protect your home from moisture and flow as much as possible, then the lining layer will serve you as an excellent assistant in this solution. All modern standards when arranging the roof say that for the angle of inclination of the roof of 18 ° or more (ratio of 1/3), the location of the waterproofing layer should be strictly in parallels to the end and cornice edge of the roof. Since the probability of leaks in these places is very high.

When installing this layer, it is worth noting that the technology allows laying at least 40 cm from the edge of the roof. If it is brought to the facade, then this will be the best solution. The ridge also requires waterproofing, which assumes the installation of a lining layer on both sides of the ridge by at least 25 cm, which gives additional ventilation in the roof.

When the angle of the roof of 12-18 ° is tilted, the process of flooring the lining layer changes slightly. In this case, it is worth moving from below-up, laying over the entire surface of the roof with a overlap of layers. For a faster connection of the waterproofing layer, they mainly use galvanized pneumatic grooves with an enlarged hat, driving them every 20 cm.

Cornice and end parts

After installation of the lining layer, the overhang should be enhanced using planks from painted or galvanized metal. They are attached on top of the waterproofing layer on cornices and ends. To do this, use special nails for the roof, driving them with an interval of 12 cm.

Next, a self -adhesive tile is laid, having previously removed a special protection film from it. They glue it flush along the cornice to each other. The tiles are finally fixed with nails.

If your roof has an Endov, then it is worth laying the carpet in it, fixing it on each of its sides. If, after installation, smear the carpet around the perimeter with a mastic of bitumen, this will give the structure additional waterproofing.

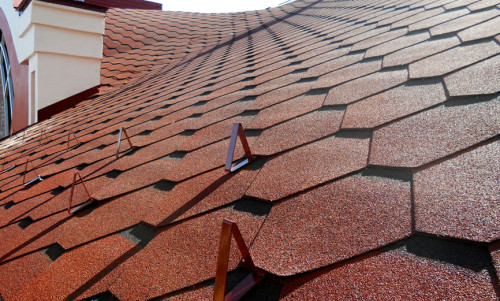

Laying flexible tiles

Starting with a flexible tile with a flexible tile with your own hands, they very often make the same mistake. When the roof is partially already covered with bitumen tiles, the difference in shades begins to catch the eye on the general plan of the executed site. This happens when you buy, for example 20 packs of tiles, moreover, 7 of them belong to an earlier batch. As a result, on the roof, the tiles look applied by "spots". This can be avoided using sheets of gont from different packs and mixed. Then the color will be uniform, although a little different.

In order to make a roof from flexible tiles with your own hands as accurately as possible and in compliance with all the rules, you need to follow several rules. Gont begins to lay from the lower part in the center of the cornice with vertical rows. At the same time, the first row is placed with a gap of about 20-30 mm between the lower edge of the gunt and the cornice tile. In order for the drawing to be formed beautifully, the edges of Gont in the second row are cut in the center, thereby closing the fastener of the first row. This is usually done along the edge of the cornice of the pediment and then processed with a glue strip of bitumen with a width of about 10 cm.

Also, the sheet is also nailed with nails (4-5 pcs per sheet). And since the tile is laid in layers, then driving a nail into the first row, you strengthen the second at the same time.

Adjacent to flexible tiles

If your house has a stove pipe or other items adjacent to the roof, and there are definitely such, this method of installation of adjoins will be relevant for you. For example, we will analyze the chimney. There is always a small clearance between the pipe and the roof, into which water often enters, thereby getting to the roof.

In order to avoid this problem, come as follows:

- a rail is nailed to the corner between the roof and the pipe (better than a triangular shape);

- the tile is made on this rail and a pipe;

- the carpet is laid, starting from the pipe (with a protrusion of 30 cm);

- the pipe is placed in an apron (covered in a circle with sheets of galvanized or painted tin);

- the pipe is installed in the light (to do it stands close to the pipe to protect the roof from the accumulation of precipitation).

If some communications need to be brought to the roof, special passing elements intended for tiles are used. They are nailed to the base of the roof with nails, thereby protecting it from leaks.

And finally, a special tile (ridge) is laid on top of the ridge. It consists of three perforated parts. They are laid on each other with an interval of 50-60 mm, while a short part of the ridge tile is located parallel to the slope line. It is also attached with nails.

Finally, we offer to get acquainted with an informative video about the roof of flexible tiles with your own hands: