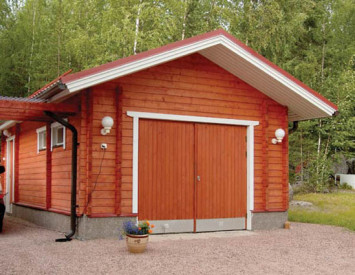

A garage for your car can be built from almost any material. Build your garage from a beam is a reasonable solution. The beam has several advantages that other building materials do not have. By acquiring a cut and strugan beam, select the one that has already been impregnated with fire -protection solutions.

Content

Despite the fact that the garage from the beam has good heat -insulating qualities, its walls and roof are “breathing”. They pass water vapors, exhaust gases and neutralize smells. In addition, a wooden beam is light in processing and is an environmentally friendly material. When planning a garage from a beam, a photo can be found on the Internet, make a project indicating the size.

Stages of building a garage from a bar

View on the Internet and select the optimal for your requests a garage project from a beam. Based on the project, the calculation of materials and calculation are made. The drawings provide for a place for workshop, tools and an observation pit.

- For a garage from the beam, a pile, strip or slab foundation is equipped, depending on the condition and composition of the soil. The foundation must be at least 20 cm above the soil surface. Between the horizontal plane of the foundation and the first row of the beam, waterproofing is laid.

- For walls, a profiled glued beam made of hardwood is selected. You can order a bar prepared for assembly in a log house and treated with appropriate chemical drugs. Septic from decay, antiprene from fire and aquastop for hydraulic protection.

- The roof, depending on the design of the rafters, is made by gable or single -sloping, with a slope back or to the side. For the floor in the garage, a concrete screed is equipped.

- For doors and gate in the garage from the beam, reliable loops, bolts and locks are provided. The doors and gates are made of metal or a cohesive board and strengthened with metal stiffeners.

Types of foundations for garage from a bar

Different soil composition requires a certain type of foundation for the structure. On heavy heaving soils, a slab foundation is used. For a flooded area, it is better to equip a pile foundation. The strip foundation is poured in dry and static areas.

- The strip foundation for a garage from a wooden beam is the most complex and time -consuming. Along the perimeter of the base of the garage, a trench is born at the rate of at least 0.5 meters in depth and 0.5 meters wide. A shield formwork is equipped in a trench, and a metal skeleton is knitted from a reinforcing bond. The formwork is progressively, in layers about 20 cm thick, poured with concrete solution. Having reached the calculated height, the foundation is left for drying. In sunny weather, it is moistened, and in rainy they are covered with a film. Further work continues no earlier than in a month.

- The columnar foundation is the simplest and does not require special costs. Such a foundation is set within one day. In key places in the corners and points of critical loads, pillars are dug up to a depth of at least 1.5 meters and are connected by horizontal randbalks. For supports and beams, reinforced concrete pillars are most often used.

- The slab foundation is a continuous reinforced concrete slab, slightly protruding beyond the perimeter of the garage from a wooden beam. A drainage pillow from compacted sand and crushed stone is made under the plate.

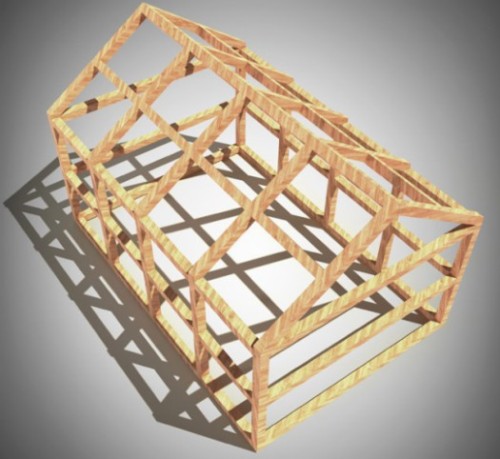

Construction of the frame for a garage from a bar

For the frame base of the garage, a trimmed strogen beam of solid wood is selected. A bar of oak, larch or beech with a cross section of 100x100 mm is used.

- The corner units of the frame L and the figurative are connected at an angle of 90 ° by a carpentry connection to the mustache and spike. The simplest compounds are made in half a term, and the most durable are on a triple spike and fixed with a wedge.

- For rafter paws, an angular handicraft is made under a oblique spike. All corner compounds are additionally fixed with metal bolts, brackets and corners. The assembled frame from the beam is installed on the foundation.

Blood wall walls from a profile beam

Garages from a profiled beam are usually built without a frame. The bars are mounted by a farbic, well or without release - in a paw.

- The horizontal plane of the basement of the foundation is coated around the perimeter by waterproofing mastic or laid by bitumen tape. For waterproofing, a roofing or rubemast is sometimes used sometimes. It is not difficult to build the walls of the garage from the beam with your own hands.

- The lower embedded beams are exhibited. Particular attention is paid to the corners. They are checked by a carpentry corner both from the inside and outside. Diagonal distances are measured and only thoroughly verified beams are attached to the concrete base. Metal crutches are used for fastening the beams. In the embedded beam, the grooves of the lag of the floor are cut under the flooring of the floor. The distance between the lags is from 0.5 to 1 meter.

- The subsequent rows of the beam are laid out from the lower binding. Corner compounds are attached into the paw, in the floor or on the spike. Between themselves, the rows of a wooden beam are connected by dangers. For this, through holes are drilled, and a wedge from solid wood is driven. The wedge is recessed several millimeters into the hole, so that when the beam is vulgar, it does not protrude out. In the process of laying a wooden beam, the verticality of the walls, the correct angles and diagonal dimensions are periodically checked.

Installation of roofing rafters and garage garage floor

- Rafting legs crawl into the upper cornpower row of the beam under the roof. For a gable roof, the rafters in the place of the ridge are connected to the "hollow". For a flat pitched roof, the rafters are attached with a slope of at least 15 °. A crate is stuffed on a rafter beam. For a hard roof, the crate board is stuffed with a step of 50 - 70 cm, and for a soft roof, the crate is equipped with a continuous flooring.

- A waterproofing film is attached to the crate. It is freely rolled on the plane of the roof and grabbed along the edges with upholstery cloves with a wide hat. The heater for the roof is attached from the inside between the rafter boards and is filled with a lining.

- Any roofing material is suitable for the roof of the garage. For hard roof, slate, corrugated board, metal tiles, etc. are used. The roof is attached with special slate nails or roofing screws. Under a soft roof of the type of roller rubber, or roofing material, a base of waterproof OSB or plywood is required with a thickness of 10 - 12 mm. The soft roof is equipped with a hot method - by fusing or glued to bitumen mastics.

- A wooden floor for a garage from a beam is equipped from a dodgy board of at least 5 cm thick. The board on the lags is attached with nails or self -tapping screws. Free cells between the lags are falling asleep by expanded clay and medium fraction. All wood in the garage is covered with an antipyren composition to prevent a fire.

Swing and lifting gates for a garage from a beam

The garage gates are made durable, with reliable locks and strong loops. The lifting section gates are installed by specialists.

- The metal sections of the gate are equipped with a torsion mechanism and are automatically triggered for opening and closing. The gate canvas is made of metal sandwich panels and when the gate is opened, it rises under the ceiling.

- The swing gates can be made independently. The frame frame is made from a 50x50 mm frame, wrapped in a board or a beam, and is strengthened by stiffeners. For reliability, the gates are sheathed around the perimeter with a metal corner and strip. The swing gates are hung on special garage loops.

Reliable locks and internal bolts - a guarantee of the safety of your car.