Penoblock is a material in the form of a rectangular parallelepiped size of 30 by 40 cm. Blocks of foamed concrete are made, which is mixed with cement, water and sand. The material is characterized by a gray color and the ability not to sink in water, even having a fairly large weight. The foam block in some characteristics is similar to aerated concrete and often confused it with this material. But for foam blocks for the foundation, the price is much lower than the cost of aerated concrete, because this material in construction is used more often.

Content

Advantages of using foam blocks

Foam blocks differ in a low cost in comparison with other similar materials, while the buildings from it have the same indicators as from brick or wood. In addition to this factor, there are other significant advantages:

- In the manufacture of foam blocks, no harmful impurities are used, this material is environmentally friendly and does not harm human health and the environment. According to sanitary standards, foam block is suitable even for the construction of various children's institutions.

- The walls of foam block do not let sound and do not require additional soundproofing.

- The surface of the bricks made of foamed concrete is easily processed, constructions of any shape are created from it.

- The porous structure of the material provides good air exchange between the room and the street. This indicator is at the same level as the wooden walls. At the same time, they do not conduct heat, holding it indoors.

- The foundation of foam blocks will not be damp due to the same porous structure of the material. The installation of additional structures is not required to combat high humidity in the basement.

- When laying foam block, all work is performed quickly and easily, since all bricks have a small size and correct shape.

- The maximum distance between the bricks is 3 mm, so not only cement, but also special glue is used for laying.

- When finishing buildings, the laying of a large amount of plaster is not required, since the walls of foam block have an even surface.

- This material is highly resistant to heating.

With all the advantages of foam blocks, they have one drawback - the strength is not very high, this should be taken into account when calculating the load on the foundation.

Types of foundations from foam blocks

In order to determine exactly what the foundation for foam blocks is needed, it is necessary to study all possible options, as well as the characteristics of the area on which construction is planned. The most common grounds for buildings from this material are divided into 4 types:

- The strip foundation - this design is constructed by buried or finely chased.

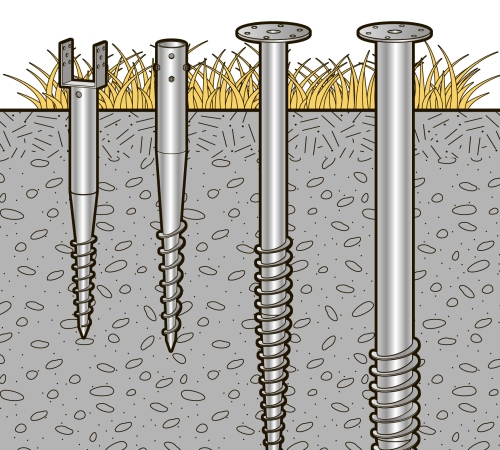

- A columnar foundation - the structure includes reinforced concrete, pillars in the form of a square or a circle with a grillage or beam that has a reinforcing belt from the reinforcement.

- Pile foundation-during the construction, piles of screw or hanging, pile-strokes with a grillage made of reinforced concrete are used. The fundamental difference between this type of foundation is only in the presence of strengthening pile elements. Otherwise, the design is built as a strip or columnar. Piles are optimal for unstable grounds that need additional support.

- A monolithic foundation - according to the principle of construction, does not differ from such structures from other types of material. The design of foam blocks has a slight weight, and therefore the thickness of the base is less made, but this factor depends on the project of the house, its number of storeys and area.

Pentiles type selection parameters

When choosing the best option for the foundation for a home from foam blocks with your own hands, take into account the features of the area on which construction is carried out. The foundation should be reliable, as it is the basis of the house, but at the same time the calculation is carried out in such a way as to maximize the costs. In more detail, all the factors that take into account when choosing the type of foundation are described below:

1. Features of the soil at the site of construction. To determine the type of soil, geological studies are carried out, which are carried out by specially trained people. But this work is easily carried out independently. To do this, with a drill, one or more wells with a depth of not more than 2.5 m are made. Earth samples are taken from these wells to determine the components of the components. In groups, soil types are divided into:

- non -bonus, contain gravel sand with large or medium size of grains of sand;

- low -bundled, contain grain grains of small size or sand dust;

- floody, contain impurities of clay, loam and sandy loam.

2. Further from the analysis, the optimally suitable type of foundation is determined. For the third group of soils, you should not choose a strip foundation. The best solution will be piles.

3. If soils from the first group are present at a depth of more than 2 m, and freezing passes at a fairly large depth, then it is advisable to build a column or pile foundation structure. When calculating, the pillars or piles are placed so that the distance between them corresponds to the total mass of the structure. The depth of freezing of the soil is determined on the basis of observations of several years, on average this indicator is from 0.5 to 2 m.

4. The next factor is the level of groundwater and its impact on construction. Highly standing waters exclude the construction of a strip foundation, this indicator is 0.5-1 m. With this height, it is necessary to supplement the foundation with drainage, which will increase the cost of work. In this case, the best option is a monolithic foundation. However, if it is planned to build a house with a basement, then the construction of a strip foundation and drainage for it is inevitable.

5. The last factor is the necessary terms of work and their cost. For quick construction, the foundation is the foundation of pile or columnar, since these work requires the smallest time. The most expensive foundation for a home from foam blocks is monolithic and strip.

Penoblok tape foundation

The tape ruined base of foam blocks is optimal to build on soil made of clay or soils from a group of heaving type. The laying depth is calculated based on data on the freezing of the soil. The width of the foundation for the foam block is calculated so that it is more than the thickness of the wall at least 100 mm. The height of the basement is not less than 40 cm, the upper part is reinforced with a 10-16 mm reinforcement in two rows in two layers.

The low -pound foundation has a laying depth of not more than 60 cm. This type of base is optimally suitable for non -poured soils with a strong base. Ribbon foundations allow you to equip a house with a basement. The algorithm of the construction of the structure looks like this:

- The process begins with a pillow laying, for the manufacture of which sand or a mixture of crushed stone and sand is used. They prepare a trench for the base of the house, sand is covered in it, trim, and then crushed stone or gravel is laid on top. The thickness of each layer is 15-20 cm.

- Next, a cement mortar with a thickness of 5-10 cm is poured onto the finished pillow. This part is called the “vitality”. The solution is left for 5-7 days, but not until completely dry, but only to half.

- When the "vypotton" dried up half, the foundation is reinforced. The reinforcing rods are tied into the belts with a knitting wire. It is not recommended to fasten the rods with welding, since the places of exposure are more prone to corrosion. The reinforcement for the foundation should be selected from products that have an anti -corrosion coating. If necessary, the foundation is reinforced using a more complex frame, which is additionally poured with concrete. This measure is necessary with high severity of the future structure.

- After reinforcement, the formwork is performed. To do this, use wood, slate, plywood or metal material. A concrete solution is poured into the finished structure.

- To prepare a concrete solution, all components are taken in this ratio - 3 parts of sand per 5 parts of crushed stone and 1 part of cement. The ratio of water to cement is 0.5. When performing work in cold weather, various substances are added to the solution that accelerate hardening.

- Ready concrete is poured into the formwork and compacted. The best option for a good seal is a vibration farm, which is also not difficult to do with your own hands. Or seal the solution with a wooden hammer, having previously made several holes in concrete for air.

- The formwork is removed after the solution is completely hardened, it usually takes about 3 days. Next, the masonry of foam blocks begins on the finished base.

Some features of the terrain significantly affect the construction of the basics under the house. If the area has a slope, then the foundation is poured with ledges, begin work on the lowest surfaces and move on. In this case, the height and length of the ledge are calculated in the ratio of 1: 2, its height should not exceed 50 cm. With the same calculation, the deeper laying goes into small. When erecting the foundation on dry soils, the thickness of the sand pillow is increased, while reducing the masonry size.

The construction of a columnar foundation from foam blocks

The columnar foundation for the house made of foam blocks is simply perfect, since this type of structures is reliable for buildings with a slight weight, and just such a feature is inherent in foam block buildings. The construction is based on the construction of the pillars on which the entire building will be built. Pillars for pillars are calculated so that they propagate each corner and places of intersection of the walls, also with pillars enhance all points of concentration of the load - heavy or load -bearing walls, beams, runs, etc. In calculations, it is also taken into account that there should not be more than 2-2.5 m between the pillars.

The columnar foundation is built using various materials, including stone, brick, button, wood and others. The depth of the laying divides the buildings into ruined and shallow. The structural features divide the foundations from the pillars into monolithic and collapsible. If, when erecting the foundation, beams are laid on top of it, then this is a building with a grillage, but it is possible to build without it. The most reliable design, leading experts recognize the reinforced concrete columnar foundation for the home. The algorithm of its construction looks like this:

- In each place marked under the post, a hole is dug. A pillow of sand, gravel and crushed stone is laid in ready -made recesses. On top of the pillow, the material that does not let moisture is laid so that when pouring the pillars with concrete, the moisture does not go into the base.

- The shields are installed in the pits and they are bursting so that the design does not fall inside. This measure is necessary in order to prevent the sowing of the Earth into the pit. The same shields are used as formwork if their width corresponds to the necessary.

- Next, reinforcement is carried out, the thickness of the rods for this is required about 12 mm. Reinforcing material is inserted into the pit vertically, at a distance of 5-10 cm from each other. All rods are fastened with knitting wire.

- Before pouring the solution, the formwork is reliably fastened. For the preparation of the solution, 1 part of the cement to 3 parts of sand is used. The solution is poured gradually, in small portions. Every 20-30 cm cement is thoroughly tamped.

- Filled pillars are left 10-14 days until it dries completely. Next, remove the formwork and mount the overlap. Use concrete filling or monolithic concrete blocks for this.

- The floor of concrete fill is made according to the same principle as the pillars themselves. It is strengthened by nets from reinforcement.

The construction of a monolithic foundation from foam blocks

This foundation for foam blocks is optimally suitable for abyss soil. It fills the entire space under the house, while the species described above propagate only individual elements.

The minus of the structure is the inability to equip the basement. The algorithm for the construction of the structure looks like this:

- The found for the required dimensions with a depth of not more than 60 cm is equipped.

- A pillow with a thickness of 40 cm is laid on the bottom of the pit as during the construction of a tape or column base. The thickness of the sand layer is not more than 25 cm, a layer of crushed stone is not more than 15 cm. On the upper gravel layer of the pillow put waterproofing material and two strengthening layers of reinforcement. The strengthening layer consists of a reinforcement with a 10-12 mm dimeter and the size of cells of 20 by 20 cm.

- The formwork is installed over the entire area of \u200b\u200bthe monolith. A concrete solution is poured.

- After the solution is completely dried, the formwork is removed, the waterproofing material is placed.