If you want to change the boring environment in the kitchen, it is not necessary to buy new furniture. It is enough to change the facades and your "study" will be transformed. Kitchen facades can be ordered in a specialized workshop, but it’s more interesting and cheaper to do everything with your own hands. Read our article and transform the space around you in accordance with your taste and without large investments.

Content

Materials for kitchen facades

When choosing a material for the implementation of the conceived project, one should focus not only on its external beauty, but also on qualitative characteristics. In a different way, because the kitchen furniture is operated in more stringent conditions than, for example, indoor.

Requirements for kitchen facades

In order for the facades of kitchen furniture to retain a decent look for as long as possible, the material from which they are made must have the following qualities:

- moisture resistance;

- high temperatures resistance;

- ease of care;

- strength;

- resistance to damage to a mechanical nature.

Materials for kitchen facades

There are many materials for the manufacture of kitchen facades. All of them have their own characteristics and properties:

- Ground wood-bruise. Received by applying a layer of glue and paper film on the usual chipboard. Unfortunately, this beautiful and inexpensive material is short-lived due to low wear resistance.

- Plastic. The chipboard is also based on, but the coating is more expensive, therefore it is more reliable, well opposes mechanical damage, has a large spectrum of colors, moisture resistant, but cannot be restored after damage.

- Tree. These facades are solid and noble. They are performed in various styles, are subject to restoration, and repeatedly, environmentally friendly. They are made of birch, oak, nut, ash, cherries, pears, exotic rocks. As a finish, patting, varnishing, aging, coloring is used.

- Glass. The facade is completely glass or decorated with glass inserts, decorated with patterns or painted, tinted, with a photo imbalance. Sometimes for security from the inside, a reinforcing film is glued, some manufacturers use an open organic glass.

- Stone. Apply as inserts. Such facades in combination with a stone countertop look amazing. The main disadvantage is that they are very heavy, an increased mount is required to install them.

- MDF. The service life of this material is at least 6 years. The structure, as well as some characteristics, it resembles natural wood, but much cheaper. In addition, it does not lend itself to deformation, environmentally friendly, it makes fasteners well.

When choosing the material, take into account the overall style of the kitchen. For futuristic high-tech, the most suitable option is that the facades from MDF are both glossy and film. In a classic kitchen, painted aluminum profiles, wood, stained glasses look organically. In a small room, deaf dark facades are inappropriate, it is better to choose the doors with glasses - transparent or white matte.

Wooden kitchen facades

Wooden kitchen facades emitting special warmth and comfort are the most popular. They belong to the category of elite.

The category includes 2 types of facades:

- Openced are plates from fiberboard and Lee MDF lined with veneer, i.e. expensive wood plates. They are cheaper than facades from an array, but they look attractive, they are easy to process.

- Massive - made of natural wood pre -processed using special technology. Sometimes a thread is applied to the facades, artificially aged, using a patina, turning kitchen furniture into works of art.

The cheapest among facades for the kitchen from array are those made of pine. Dear, elite facades are made of red wood, wenge, cedar.

A selection of photos of the facades for the kitchen made of wood

Aluminum facades

Aluminum facades for the kitchen look stylish, modern, interesting, perfectly combined with other materials. They have many advantages:

- do not burn out in the sun;

- resistant to temperature differences and moisture;

- durable;

- lungs;

- ecologically safe.

In addition, kitchen aluminum doors can be made not only swinging, but also sliding.

There are also disadvantages:

- high cost than facades from MDF, plastic and other artificial materials;

- fades over time;

- damage to contact with acute objects and from the use of abrasive cleaning agents.

Types of aluminum facades

There are two types of facades from this material:

- Continuous or slab. They are made of a whole sheet of grinded aluminum. It goes well with household appliances that has chrome surfaces.

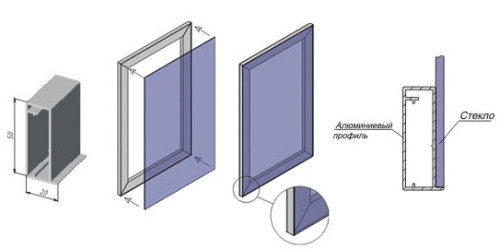

- Framework is a design consisting of:

- from the frame;

- filler;

- fasteners;

- fittings.

As a filling material, inserts of glass, wood, plastic, PVC, MDF, chipboard or their combinations are used.

Good to know: Another advantage of the facade from the aluminum profile is that the frame is versed, so its filling can be changed.

Facades for the kitchen from MDF

This group of facades is the largest. There are several types of such facades:

- Openced - visually the surface is difficult to distinguish from natural wood.

- Colorful - the surface is glossy, looks perfect in any interior. The product is first primed, then covered with enamel in several layers. The surface of enameled facades from MDF is matte, glossy, silky, mother -of -pearl, flickering. They do not absorb moisture, but under the influence of ultraviolet rays, the painted surface burns out.

- Laminated - an analogue of the version of chipboard, covered with a film of PVC, simulating marble, plastic, wood, metal and other materials. They are relatively inexpensive, but have one unpleasant quality - under the influence of moisture and heated air, the film lags behind the base.

- Plastic - durable, are not afraid of hot air, but the surface is extremely smooth - other options are impossible.

Acrylic facades for the kitchen

The basis of these facades is the MDF plate or chipboard covered with polymethylacrylate, which is plastic obtained using special technology. The surface is perfectly glossy. The thickness of the acrylic coating is about 0.2 cm, the entire plate is 1.6-1.8 cm. Acrylic facades are performed in two versions:

- one -sided when the plate is covered with acrylic only outside;

- double -sided - acrylic coating is present on 2 sides.

These facades are in demand due to a number of positive qualities:

- the surface is perfectly flat, glossy;

- resistance to all kinds of deformations is high;

- the colors are deep, saturated, resistant to changes under the influence of the environment;

- heavy metals, carcinogens in the composition are absent.

How to make facades for the kitchen with your own hands

Maybe with your own hands in some ways is inferior to the one that is sold in furniture salons, but it is exclusive and not so expensive. Most often, they independently make facades for a kitchen made of array, phylene, from chipboard.

Making facades for a kitchen made of wood

In order to make a wooden facade, you need a wooden shield 2-3 cm thick or a boiled pine boat 20 cm wide, fittings, stain, varnish, screws, as well as the following tool:

- kiyanka (1);

- set of saw - ray frame (2), groove (31), spiked (32), locksmith hacksaw (33);

- clamp (3);

- transverse clamp (4);

- metal line (5);

- fugan (6);

- locksmith hammer (7);

- malka (8);

- flight (9);

- square (10);

- file (11);

- current cutter (12);

- strong (13);

- partsovy rubbish (14);

- roulette (15);

- circuls - dividing and simple (16, 17);

- pencil (18);

- knives - big, small (19, 20);

- fORTER drill, spiral (21, 23);

- cross screwdriver (22);

- a cutter used to drill plugs (24);

- zenkovka (25);

- end keys (26), divorce (28);

- roundbones (27);

- electric sales (29);

- a chisel with a faceted blade (30).

Attention: The wood should be dry, a maximum of 10% humidity is allowed. Boards with large knots, resin pockets, cracks, insect damage are not suitable.

We begin everything with measurements and the preparation of the project. In order for the cabinet doors to open normally to accurately calculate the width of the facade. It is equal to the size of the opening plus 1 mm. Next, we carry out work on the following technology:

- We lay out the boards on a wide even table, fix and transfer the measurements from the project, marking the cut lines.

- Cut all the elements.

- Grind the blanks.

- We clean the ends using sandpaper.

- We perform holes for fasteners.

- We apply an antiseptic.

- We connect the parts, for which we apply glue to the ends of the blanks, level the corners, clamp everything in the clamp, until it dries.

- We process the facade with a stain.

- We cover with varnish 2-3 times, each time removing irregularities with fine sandpaper.

- We fasten loops, accessories for what:

- we determine where the loops will be placed on the walls of the cabinet;

- we mark the installation sites of the fasteners on the facade;

- we fasten the loops to the facade;

- we insert the door into place and fasten it to the case so that there are no gaps and distortions when closing.

Production of Philineral facades

To update your kitchen using Philnah facades, you will have to purchase a board about 20 mm thick for a frame and a plywood with a thickness of 6 mm for Philoi. The sequence is this:

- we make a frame, for which we cut out 2 vertical and 2 horizontal parts;

- we make in the elements of the framing from the inside of the groove to a depth of 10 mm and a width of 0.6 cm;

- we cut a phylenka from plywood - the inner panel;

- we perform on the horizontal elements of the frame of the spike a width of 0.6 cm and a length of 10 mm;

- grind all the elements, including spikes and grooves;

- we put on a framing on the phylenka, adjust the landing;

- apply glue in the grooves, on the spikes, the ends of the phylenka;

- we collect the facade, inserting the phicen into the frames of the frame, additionally fix the joints with self -tapping screws;

- leave to dry;

- grind the joints;

- apply the antiseptic composition;

- we perform the finish;

- we fasten the loops, install in place, mount the fittings.

Keep in mind: plywood can be replaced by glass, MDF, forged parts, polycarbonate, plastic.

Facades for the kitchen in an aluminum frame with your own hands

The facade of aluminum profile combines 2 material - an aluminum frame and a phicen. Such a tandem prevents deformation, increases durability.

To make such a facade with our own hands, we act according to this algorithm:

- We cut out a phicen from any material you like, and make it 2 centimeters more than both length and width. If it is chipboard or MDF, then glue the plastic on top, load evenly on top and let dry.

- Choose an aluminum profile of the corresponding section.

- We perform pruning, given the thickness of the profile. We measure the profile, while when it is planned to decorate the corners using decorative corners, the length of the profile is equal to the corresponding size of the edge of the phylenka. For the manufacture of a frame without corners, we cut the blanks longer than the edge of the insert into two thicknesses of the profile. Suppose that the length of the insert is 500 mm, the thickness of the aluminum frame is 4 mm, then the length of the workpiece is 500 + 8 \u003d 508 mm. This is necessary to join the bar at an angle.

- We fasten the profile to the panel using a stapler or small nails.

- We cut off the plastic insert along the length of the profile, insert it with one end into the groove and push it, thus closing the mount.

- In the established part of the frame we insert a decorative corner, cut off the end profile and join these two parts.

- In this way, we make a complete framing, but we mount the last 2 details at the same time so that you can arrange the joint with a corner. If there are no corners, then we do this:

- cut a piece of material designed for inserting at an angle of 45 degrees;

- we dress the profile on the cut, cut off with a saw.

Details and some nuances in this video:

All materials for the manufacture of kitchen facades have their pros and cons. Some are cheap, but short -lived, others will last for many years, but they will cost expensive, but you can save significantly by performing facades from expensive quality materials with your own hands. Experienced furniturers provide training video for this: