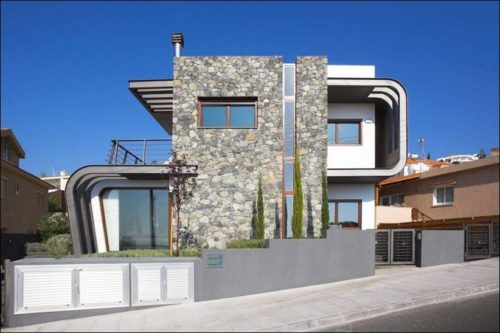

To give the house a nice appearance, at different times resorted to different techniques using various materials. To distinguish your own structure among the common mass, you must try to try to preach. After all, the building should not only look good, but also to cope with its main function - the preservation of heat inside the room. To enjoy the facade of the dwelling, the decorative plasters of various species are increasingly used. Work on the application of facade decorative mixtures is rather difficult. Having learned all the subtleties and nuances of such a finish, you can fulfill everything yourself without spending unnecessary tools.

Content

Selection of facade decorative plaster

To determine the choice of one or another type of decorative facade plaster, it is necessary to carefully understand its properties and distinctive features. It has many criteria that will help to stop their choice, preferring one way or another.

Distinctive features of facade plasters

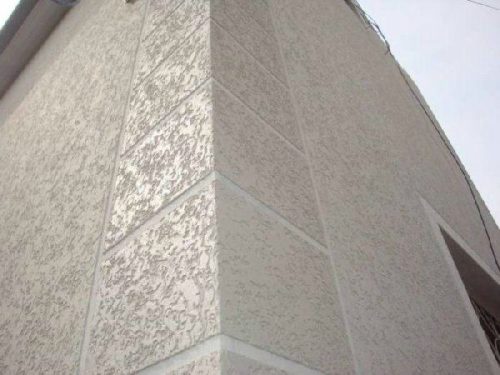

The main function of such a coating is definitely - protection against external factors capable of destroying the main structure. In addition to protective functions, the facade coatings also perform a decorative role. Having gave the facade of his own home a unique texture, you will get a great result that will enlighten the neighbors. Decorative facade plaster, in contrast to other finishing mixtures, has special properties, since all the work is carried out outside the room.

The main distinguishing features of the facade plasters include such properties as:

- moisture resistance (protects the facade from moisture ingress capable of destroying the structure. The facade coating does not change the shape under the influence of precipitation, forming a kind of protective layer for the house);

- resistance to temperature drops (the facade coating will perfectly protect the buildings located in the regions with significant climatic changes during the seasonal transition);

- resistance to radiation compounds (some types of plaster are able to protect the structure from harmful radiation, for example, if it is located near NPP or other industrial objects);

- strength (decorative coating perfectly protects the facade from random mechanical damage, since it has a rather dense structure);

- heat regulation (besides the fact that the plaster perfectly delays heat, it exceeds the overwhelming vaporization. It prolongs the service life of the building, allowing it to "breathe");

- soundproofing (applying such a coating, you will additionally protect the house from external noise);

- thermal insulation (in warm regions just apply only decorative coating, without using insulation systems. This avoids the costs associated with installing additional heating elements);

- design (the facade can be placed in various types of mixtures using various application techniques. Improvisation during finishing works will give the building a unique appearance. Using the caloring paste you liked the colors, add brightness and individuality facade. You can also use specially prepared stencils that will give the surfaces of a special texture) ;

- simplicity of application (such work forces to everyone who has at least the slightest idea of \u200b\u200bconstruction plaster);

- the price (the cost of facade plaster mixtures is relatively low. The huge variety of manufacturers and species of this material will allow you to choose plaster on the pocket. Pricing depends on the ingredients contained in the mixture, as well as the finish coating structure).

As you can see, there is a lot of benefits of such a coating. All of them make decorative plasters on the first position in the list of finishing materials for the facade of the building. A huge selection of this material and flexible pricing policy will make it possible to choose the necessary coating to almost anyone who has a stable income.

Types of facade ornamental plasters

After we disassemble the general distinctive features of this material, it is time to highlight the main types of plastering mixtures used in the arrangement of the facade of the house. All of them have common protective properties, but do not forget about decorative qualities. Each species is designed to reflect the outdoor part of the house on its own taste.

To plaster building from the outside, use decorative facade plates of the following types:

- Cement. As the main ingredient, cement is used for such plaster, which is mixed with sand of different fractions. To achieve the necessary texture, use various elements, such as marble or granite crumbs. To achieve high operational indicators, special additives and impurities are used. Facade cement-based plasters have a very durable finishing coating that can protect the structure from a detrimental effect of climatic conditions. This coating refers to the "breathable" due to excellent indicators of vapor permeability. In addition, cement facade plaster has good environmental qualities, because it does not burn and does not allocate harmful substances under the influence of high temperatures.

In order to qualityly paint such a facade, mineral paints use. This type of plaster is referred to inexpensive facade finish options, since it consists of relatively cheap ingredients. In addition, it perfectly falls into almost any surface or insulation system. For better fixation, a plaster mesh is used. But it is worth considering that the color palette and the range of such a plaster mix are sufficiently small. Perhaps you will have to additionally post a certain amount for the purchase and tinting of the material necessary to cover the facade in the desired color. To choose a good cement plaster, it is better to buy a ready-made mixture, rather than making it personally. Compliance with the proportions of compound ingredients directly affects its strength and durability.

In order to qualityly paint such a facade, mineral paints use. This type of plaster is referred to inexpensive facade finish options, since it consists of relatively cheap ingredients. In addition, it perfectly falls into almost any surface or insulation system. For better fixation, a plaster mesh is used. But it is worth considering that the color palette and the range of such a plaster mix are sufficiently small. Perhaps you will have to additionally post a certain amount for the purchase and tinting of the material necessary to cover the facade in the desired color. To choose a good cement plaster, it is better to buy a ready-made mixture, rather than making it personally. Compliance with the proportions of compound ingredients directly affects its strength and durability.

- Silicate. Refer to mineral plaster mixtures, since it contains potassium liquid glass that binds all ingredients. As filler use water, stone crumb, sand, as well as other additives, which improve the performance characteristics of such a coating. The binder, in this case, plays an important role, protecting the facade from the wind and moisture. Silicate facade plaster is perfect for concrete or lime-concrete bases. It has excellent durability, fire safety and vapor permeability. The finished coating can be painted in any favorite color using the silicate paint.

Since all ingredients have a fairly high cost, then this plaster is related to expensive types of finishing material. Choosing this facade coating, do not forget to consider that its use is unacceptable for applying to some types of foundation. For example, on polystyrene foam insulation systems, drywall and other surfaces treated with varnish or paint on an oil basis, not recommended silicate plaster.

Since all ingredients have a fairly high cost, then this plaster is related to expensive types of finishing material. Choosing this facade coating, do not forget to consider that its use is unacceptable for applying to some types of foundation. For example, on polystyrene foam insulation systems, drywall and other surfaces treated with varnish or paint on an oil basis, not recommended silicate plaster. - Acrylic. An aqueous dispersion of acrylic resins acts as a binder component. It is mixed with sand, stone crumbs and other protective additives, adding a pigment like this. Most often, such plaster mixes are sold already in the finished form.

Acrylic facade plasters are inherent in high rates of wind and moisture protection. Due to its elastic properties, the probability of cracks appearance as a result of shrinkage or climate change is almost equal to zero. This plaster is very well applied to most surfaces, and the finished coating has excellent indicators of strength and resistance to abrasion. Please note that the use of this facade plaster is unacceptable for applying mineral wool. In addition, acrylic plaster badly protects the facade from ultraviolet radiation. - Silicone. As the main binder ingredient, a silicone resin is used, which is mixed with mineral fillers. The finished layer of such a coating is quite thin, which perfectly affects the consumption of material. It is referred to expensive finishing materials for facades, however, the high price is justified with its excellent operational qualities.

Facing the facade of this material can be performed with almost any weather conditions. Color pigments have a wide spectrum, besides almost unborn under the influence of ultraviolet rays. The finished surface has a very long service life (more than 10 years), and also perfectly protects the facade of the house from climatic exposure. It is worth considering that silicone plaster cannot be applied on top of insulation systems. If this is still needed, you must first create a base layer using the reinforcing grid. After that, you can already apply a decorative layer.

Selection of facade decorative plaster

Before applying decorative plaster on the facade of the building, it is necessary to determine the desired result. This is an important point, since each texture provides one way or another method of applying. It is better to disassemble every variety in detail to avoid further unpleasant situations related to the restoration of the facade coating.

To bind the outdoor part of the structure, the following types of textures are used:

- "Coroed" (a very common view, due to its availability and a relatively low price. The necessary relief is achieved due to the stone crumb of different fractions in the mixture. The final result is similar to wood sprayed by insects, hence the name);

- "Barashek" (as well as "Coroed". The necessary invoices are achieved due to the compositions contained in the composition of various sizes. As a result, a soft-tangled surface is obtained, similar to a ram fur);

- "Shuba" (achieve the desired relief allows the filler. Application technology, in this case, does not play a special role);

- "Cropa" (the fine-tight surface relief is achieved due to the large fraction as part of the coarse grains. Otherwise, such an invoice is also called a peasant plaster. It is important that all the grains are the same size);

- mosaic (this type of texture is inherent only by silicone and acrylic plaster mixtures. The binding material is transparent, and the role of the mosaic performs the stone crumb of the same size. Often, the crumb is multicolored, which gives a special kind of facade of the building);

- color (the composition of such decorative plaster includes: sand, limestone and dyes. Basically used in facing of aerated concrete, tuff and brick. The necessary textures are achieved using a special tool and forms, with which a plastic solution gives the necessary view. Often use a typeset and combined Application technique);

- stone (belong to cement decorative plasters, implying one of the most complex cladding methods. Application technique provides for the preliminary treatment of a mixture with hydrochloric acid, after which it is washed. So you can simulate the surface of solid rock rocks, such as: limestone, marble or granite. In The composition of the stone facade plaster most often includes granules of natural stone and other binding supplements);

- terrazitic (the finished surface looks like a tuff or sandstone. This effect is achieved, due to the mixture that are in the mixture: cement, lime, mica, stone and quartz crumbs. Such plasters are used for cladding and finishing of almost any premises and facades. Feature works with a terrazitic mixture provides for processing of hardened solution with sandblasting);

- graphite (it provides for a multi-layer method of applying the mixture. For this, several solutions are in different colors, after which they begin to gradually apply. At the end, it is started to cut the drawing to the raw top layer, right up to the base. As a result, a volumetric colorful pattern is obtained).

As you can see, decorative facade plaster are rich in the choice of textured and design solutions. To determine the desired result, weigh all the "for" and "against" one or another. Do not forget about the cost and purpose of the future decorative coating. It is also important to also take into account the technology of applying and other features inherent in various types of facade plasters.

Application of facade decorative plaster

When with the choice of species and texture of the plaster mixture, you can proceed to the facing of your structure. However, before doing this, it is important to correctly calculate the material. Making all the calculations in advance, you save yourself from a headache associated with the absence and delivery of missing material.

Consumption of decorative plaster

Calculation of the flow of facade plaster must be produced, given the following parameters: the base material, surfaces of the surface, the nature and size of the filler and the binding substances. Often, manufacturers indicate the approximate consumption of the mixture on the factory package, however there are averaged data that will help produce all the calculations more precisely.

For each type of decorative facade plaster, there are the following material consumption indicators:

- for mineral (2.5 - 4 kg / m²);

- for acrylic (1.5 - 3 kg / m²);

- for silicone (2.5 - 3.9 kg / m²).

Reaching this stage with all attention. Do not forget that it is always better to add 5-10% to the result. This is done to take into account working losses, besides, this stock will save you from an extra trip to the construction store. Since the facade decorative plaster can be delivered by different parties, the color and structure may be a bit different. Choose a mixture that is dated with the same number. Do not forget that there are many online calculators that allow you to produce all the calculations more precisely and faster.

Tool

When the amount of material is estimated, it is time to get all the necessary tool that will help perform all cladding work quickly and efficiently. Choosing the right tools, you will achieve the best results.

To separate the house outside with the help of decorative plaster, use the following tool set:

- perforator, mixer, drill;

- hammer, knife, set of spatulas of different sizes, bucket, trowel, celma, twink, semi-leather;

- level, rule, square, plumb;

- bath, rollers, brushes, vendors, telescopic stick, scaffolding;

- gloves, helmet, protective glasses, safety equipment.

Such a set will help you fulfill all facing work quickly and safely, besides will be useful in the future to arrange other parts of the house.

Preparatory activities

The quality of your facade will depend on the correctness of the work at this stage. Perform all actions correctly to avoid unwanted consequences related to the restoration and repair of the outside of the building.

In order to prepare the surface to apply the future decorative coating as follows:

- Explore the surface for the presence of protrusions and depressions. Remove obvious formations with a perforator or hammer. Deep cracks make a special solution.

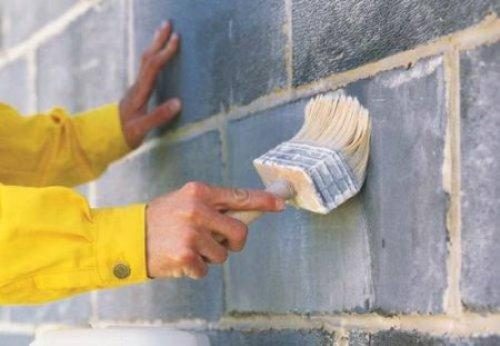

- Depending on the type of surface, process it with special means that increase the adhesion of materials (concrete contact, primer, etc.).

- Set plaster beacons vertically with an interval of 1.5-1.8 m. Use point fixation using start-up plaster on a cement basis.

- Check the overall level of the wall using the level and rule. Start tying the primary plaster with the bucket. Lay the surface using the rule, moving gradually. Excess the solution, using a spatula.

- Sprouter the surface and begin to warm the facade (if necessary).

- Apply the finish shlatovka to hide small irregularities. Apply primer again.

If you did everything right, then you should get a flat surface, ready to cladding with a decorative plastering mixture. These actions at the preparatory stage are the same for all types of surfaces.

Decorative stucco finish

The principle of facing the walls of the facade is the same for any kind of surfaces. Only some features at the preparatory stage are different. Different surfaces require different materials necessary to increase the adhesion between the layers.

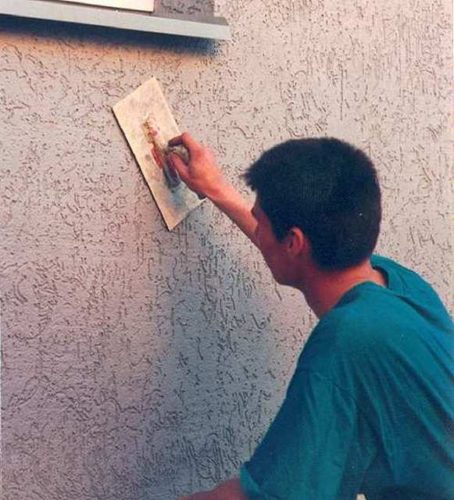

The facade is lined with decorative plaster on the following principle:

- Apply the first layer with a thickness of up to 5 mm. It is called "spray", as it is made of liquid plaster. The first layer is designed to improve the adhesion between subsequent materials and dries about 2-3 days, depending on the manufacturer's company.

- To align the surface, as well as to provide the facade of the necessary moisture protection and thermal insulation, the following layer is applied - "soil". It is more thick and has a thickness of up to 20 mm.

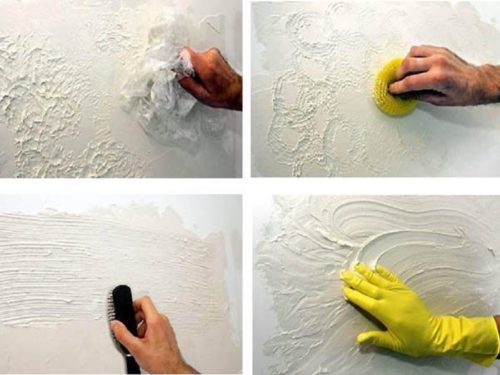

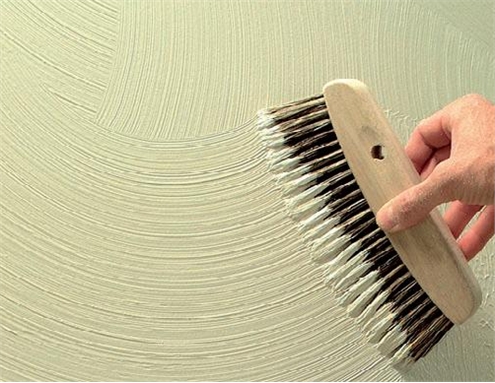

- After complete drying of the previous layer, the latter is applied, the so-called "cross-". It is applied tight, using a half-year to avoid breaks. Layer thickness - up to 5 mm. Depending on the properties of the material and the degree of curing of the coating, use a different tool and text application technology.

For example, to give the desired texture with decorative plaster with the content of lime, it is better to operate while it is in plastic condition and did not froze. In case you use a cement-containing solution, then you need to wait for a complete surface drying.

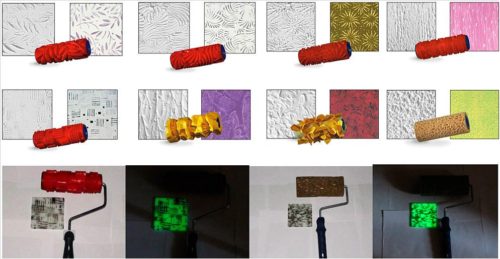

To achieve deep relief forms, it is better to process the plaster in the raw form. To do this, use special textured rollers, plastic or metal spatula with jar of varying degrees of depth and forms. Great rags, sponges and other remedies are perfectly suitable, it all depends on what kind of єffectі VI want to achieve.

To make a light roughing texture, use the brush-ending. Do not forget that for a smoother picture, a frozen embossed surface is better to be processed using emery paper. This will help get rid of gross hardened growths.

To better understand the process of applying decorative plaster, we advise you to see the following video:

Facade Decorative Plaster - Tips

If you have chosen the decorative facade plaster as a finishing material for your home, then when it is used, it is better to pay attention to some features that will allow you to produce all work efficiently and quickly.

To better bind the facade of the house with decorative plaster, take advantage of the following tips:

- consult the store with the seller about choosing a decorative mixture. Most likely, you will advise the imported option of plaster. It will be a bit more expensive, but will serve longer;

- conditioning at temperatures from + 5 ° C to + 30 ° C;

- when working in dry weather, moisturize the surface with a spacing or a wide brush;

- do not add water to a plaster solution, it may degrade its operational performance;

- choosing decorative plaster, pay attention to the weather conditions of your region;

- do not apply a thick layer of plaster, it can collapse. 2-5 mm thickness more than enough;

- if you have acquired a mixture, which already has the texture, then simply apply the solution to the surface. But note that no one has canceled experiments, fantasize in any direction;

- use several types of decorative plasters, then the facade will be original.

As you can see, bind the house with the front decorative plaster is quite simple, but the work provides for many "pitfalls". Failure to comply with the main rules and technology of application, can spoil all the work. Perform everything consistently, use high-quality material and tools, then the facing will pass quickly, and the result will delight the eye.