An electric warm floor can be used not only as the main heating system, but also as an additional heat source. This type of heating of the room has its advantages and disadvantages. Consider the features of how to choose an electric warm floor.

Content

Advantages

- Warm floors allow you to comfortably distribute the temperature in height of the entire room. It doesn’t matter whether the main system is chosen or additional. So, the main scheme makes it possible in any room where such heating is used to automatically maintain the necessary temperature with high accuracy. If an additional scheme is used, then the same characteristics will have local areas of heating.

- Unlike water heating, the warm floors of electric devi and coatings from other manufacturers have less inertiality, i.e. After turning on the heating, the temperature in the room will reach the mark on the controls much faster.

- If you apply an additional circuit of an electric warm floor, then you can lay the flooring on top of the old. For example, it is possible to mount in rooms where the coating is made using porcelain tiles or ceramic tiles, for example, in bathrooms, bathrooms and kitchens. In this case, heating electrical mats are usually used.

- If it will be necessary to repair electric heating, you will not need to engage in opening the entire gender. Taking advantage of special equipment, it is possible to determine without much difficulty in which place there is damage to the heat cable. To restore it, it will be necessary to open only a small area of \u200b\u200bthe floor. You can repair the cable if you use special couplings. When touching the damaged electric cable or its parts conducting electricity, the protective device will turn the voltage almost immediately.

- The advantages include the fact that these floors can last a long time. Some manufacturers call the service life of their products up to 50 years. At the same time, in the manufacture of coatings, only environmentally friendly materials are used.

Flaws

- The main drawback of this type of heating is that it consumes electricity quite a lot, especially if the warm floor is used in the room as the main heating system. For the same reason, restrictions on the use of such coatings in houses that are more than ten years are imposed. Here you can use such systems only as additional heating. This is due to the fact that in old houses, power supply is calculated according to outdated standards. Also in this case, overload of the power cable is possible. In general, before using the warm floor of the electric floor, even in houses built using modern technology, it is necessary to make sure that the wiring located in the apartment may transfer the load that this heating will provide. The permissible load parameters can be found in a special table. If the existing wiring does not meet the established standards, then it will be necessary to connect the system using another electrolyst and a separate automaton.

- Some varieties of such heating unevenly distribute the temperature field in the room. And if parquet and laminate were used as a floor covering, then it can be deformed over time. To prevent this from happening, strict adherence to the installation and installation technology of the floor is necessary. It is especially important to observe the depth and step of laying thermal cables.

- Due to the fact that such heating has increased electricity consumption, it requires considerable exploitation costs. For example, the cost of the floor heating, the area of \u200b\u200bwhich is from 10 to 15 square meters in two years of use can be more than the cost of the equipment itself.

- Some experts believe that such heating systems have a harmful electromagnetic effect on the human body. True, there is no unambiguous opinion on this subject. Today there are quite a few people who do not agree with this statement. They are convinced that the warm floors of electric Turnolux and coatings from other manufacturers are environmentally friendly and meet all established requirements. Moreover, according to some studies, the indications of induction and tension in rooms equipped with warm floors, as a rule, do not exceed background quantities.

How to choose a type of flooring

- Before choosing everything you need for an electric warm floor, it is important to decide on the type of coating. It must satisfy the requirements of wear resistance, strength and aesthetics.

- It is recommended to use in the design of warm floors such materials as linoleum, laminate, parquet or board, as well as ceramic tiles or porcelain tiles. So, ceramic tiles and porcelain tiles are able to conduct heat well. And at the same time they have a small specific indicator of thermal expansion. Therefore, it is these materials that are considered the best.

- When choosing a linoleum as a floor covering, it is worth taking the one that has no insulation.

- When using the floor for the floor, its wood should be properly dried. Otherwise, it can be deformed during operation.

- When choosing a flooring, it is also necessary to take into account the quality of the varnish and glue is quite high. By this, you will avoid the appearance of harmful fumes during heating.

- Before buying, you need to find out in which temperature range you can operate lacquers or adhesive joints. Such information can be indicated on the packaging. If it is not, then ask the seller on this score, where they bought an electric warm floor.

- The main criterion by which you need to choose the flooring is the presence of a special marking indicating the possibility of its use at a temperature that is a working for the heating system.

- To cover the electric floor, do not choose a cork and thick carpets. The fact is that the cork is known for its low thermal conductivity and is also afraid of high temperatures. As for the carpets, they will play the heat -insulation function in this case.

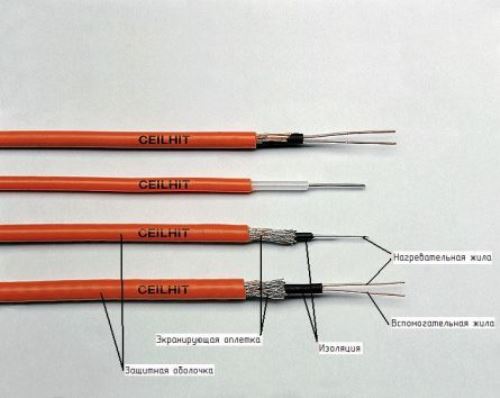

How to choose a cable

It is the thermal cable that is considered the most important element in a similar heating system. This should be clear from the device of the warm floor of the electric. Indeed, thanks to the cable, electricity is converted into thermal energy. Such a cable outwardly is very similar to an ordinary conductor. It usually has shielding. In addition, like a regular wire, a heating cable may contain one or two cores.

How such a cable differs from the usual wire is the electrical resistance of heating core. It is in it that the main core, as a rule, is made of nichrome, and this material, as you know, has a fairly high resistance. Thanks to nichrome, such a cable plays the role of a heating element. In ordinary wires, this vein is made, on the contrary, from materials with the least resistance.

In general, this cable is usually selected according to the linear power. It is a mistake to think that the greater the linear power, the more efficient the system will warm. The fact is that when laying near the surface is carried out, air cavities may form, which do not allow the heat to leave, which sometimes leads to overheating of the cable material, and this can already cause its failure. In addition, with an increase in the value of the specific power of the cable, the length that falls on a certain area is reduced. A situation may arise when an increase in the distance between individual threads will lead to uneven heating. The distance between the neighboring threads of cables of different manufacturers differs. It usually varies from 50 to 120 millimeters. If it is smaller, then this can lead to the fact that the problem of overspending of the cable arises, as well as the risk of drawing threads to the unacceptable value.

It is recommended to use heating cables with two cores when heating the children's room, living room or bedroom. One -core cables are best used as heating of the bathroom and toilet.

Cables with one residential and two veins are distinguished by installation and design. So, when installing the first - copper wiring, which connect the cable to the power grid, is usually connected on both sides. In the event that a two -core cable is mounted, then these wiring are usually connected only on one side, and on the other hand, heating and auxiliary veins should be soldered and isolated.

A two -core cable has several advantages over one -core:

- So, there is no need to connect both ends to the device that maintains the temperature. Thanks to this, it is much easier to choose a cable laying track.

- In addition, it is believed that the level of electromagnetic radiation is lower than that of one -veil.

The cables, which were described above, are also called resistive. But these are not the only existing types of cables. There are also self -regulatory heating. They differ from resistive, both appearance and the principle of work. There is no heating core in such a cable. Instead, there are two veins that are guides. In this case, the heating element is considered a matrix made of polymeric materials. It is thanks to her that these cables are self -regulating. This is achieved thanks to the semiconductor properties of the matrix. When the temperature of this heating element rises, its conductivity decreases, which in turn leads to a decrease in the value of the current through it. As a result, thermal power decreases. In the case of a decrease in temperature, the value of thermal power, on the contrary, increases.

Self -regulation allows such cables not to be afraid of local overheating, which are resistant. Therefore, when laying a cable, it will not be necessary to consider where furniture is located in the room. Their main disadvantage is a relatively high price. Therefore, they are not widespread.

In addition to the two types of cables, there are also heating mats on the sale of building materials on sale today, which are based on thin cables of low power. In the mat, they usually fit in the form of a snake and attach to a grid made of polymer material. Mats differ in power. Depending on this, they can have a width of 400, 500 or 800 millimeters. Moreover, their length can be from 0.5 to 25 meters.

The advantages of mats:

- Heating mats are much easier to mount than cables.

- High heating ability.

Flaws:

- If the floor has unusual geometry, then in this case these heating elements are not suitable.

- Their cost, as a rule, is higher than the cost of an electric floor based on a cable.

Both heating cables and mats today are on sale in two types: in the form of a finished mounting set and in the form of a separate product.

Such a mounting set usually includes:

- Cable or mat.

- Thermostat with a thermostat.

- A corrugated tube (is needed to install a thermostat on the floor).

- Instructions for installation and operation.

How to choose a thermostat

The thermostat is one of the most important components in REHAU warm floor systems. The electric floors of other brands are also meant. These devices can be both programmable and unenlightened. They are superimposed and built into a socket or mounted in an electric shutter on a metal profile.

For heating the bathroom, toilet, hallways, it is customary to use simple electric heating systems, in which non -programmated thermostats are installed. In such devices, the temperature is regulated by using a multi -position switch or using a resistor. In the first case, switching occurs stepped, and in the second smoothly.

As for programmable thermostats, they provide more opportunities for managing a heating system. So, they allow not only to set the temperature, but also make it possible to program work parameters that will operate only a certain period of time. For example, it is possible to set the parameters of turning on and off the system under certain conditions, for different times of the day different temperature ranges, i.e. The device is allowed to set different work programs. Moreover, these programs can be changed manually. Obviously, such thermostats are more expensive than unfumilized.

If it will be necessary to install the thermostat in electro-sloping, then there are devices that are mounted on special profiles, also called Din-races.

Such profiles are intended not only for attaching the thermostat, but also of other devices and electrical equipment. The metal profile is usually made of galvanized steel 0.9 millimeters thick. Its length most often is 70-1000 millimeters. There are holes over the entire length every 15 millimeters. DIN -RIKI must necessarily comply with the state standard.

Sometimes the thermostat power is not enough. In this case, it is necessary to purchase a magnetic starter that will work under the control of the thermostat. Instead, you can install a hotel thermostat for each section.

How to choose thermal insulation

Any warm floor system should be thermal insulated. This is necessary that the power of the heating system is not consumed for heating of the ceiling or soil. Various materials can be used as a heat insulator, but it is best to stop your choice on extrusion polystyrene foam, 20-30 millimeters thick and 30 kilograms per m3. If it is planned to heat the basement in this way, then the thickness of thermal insulation is required 1.5-2 times more.

The heat insulator is often used, which has a reflecting foil layer. The fact is that there is an opinion that the foil not only reflects heat, but also helps to more effectively redistribute the heat from the cable along the floor surface. But not all experts think so. There are people who are against the use of such thermal insulation, since they believe that the foil can completely destroy after three, in a maximum of five years, when it will be under the influence of an alkaline environment of a cement solution. This problem is especially important in room with high humidity. In addition, for the proper operation of such a heat insulator, an air cushion should be present between the foil and the heating element, and it is almost impossible to do this in the coating with electric heating.

Warm floors electric: characteristics

It is important to be able to correctly choose the warm floors of electric. In this case, prices are not of such leading importance as the features of a particular apartment or house. If the choice is made correctly, then the system will produce heat, which is enough for heating the entire area of \u200b\u200bthe room. In addition, it will be easy to install and economical for electricity consumption.

Today, there are several types and brands of electric warm floors on the market. Caleo is one of them. Each of the varieties of warm floors has its own configuration and a wide range of power.

There are such types of electric flooring:

- Cable.

- Cable on the basis.

- Film infrared.

Consider each of these options a little more.

Cable floor

In this type of floor, the main heating element is a cable that turns electric energy into thermal. This system is the most difficult and laborious installation. The fact is that when installing it, it is required to lay a cable with a certain step. Moreover, at the end of the work it will be necessary to fill the layer of screed.

Advantages

- The heating cable can be used for installation in rooms that differ in a complex perimeter.

- In addition, it can be used to heat some external elements of a private house, for example, castings, roofs and drains.

Flaws

- The thickness of this layer is usually about 50 millimeters, due to which the height of the room is significantly reduced. This is the fundamental moment when laying a cable floor in apartment buildings.

- This type of warm floor makes it impossible to lay it under plumbing and furniture.

Cable floor on the basis

This type of floor has a small thickness and is externally mesh, with a heating cable fixed on it with a thickness in a section of about 2.8 millimeters. Compared to the cable floor, this type of flooring is much easier to mount due to the fact that the heating wire is laid and fixed on the basis. Thus, for installation, it is only necessary to decompose and fix the mats.

Due to the fact that the thickness of the adhesive solution is quite voluminous, this type of floor is most suitable for installation under the tile. Then the mats will be directly in the thickness of the layer. If this type of warm floor is installed under the carpet, laminate or linolium, then you will also need to fill the screed, but it will not be as thick as in the case of a cable floor - usually it is about 30 millimeters. It is important that the cable floor on the basis does not fit in the areas where it is planned to put plumbing or furniture in the future, since their deformation is possible when heated.

Infrared film

This is the name of a warm floor based on a two -layer infrared film with carbon heating elements. The film usually has a thickness of about 0.5 millimeters, which is quite enough for the height of the room to noticeably change. Such a coating is considered the most energy -saving version of the warm floor systems. Its use can save about 60% of electricity. In addition, the installation of such a system is the easiest of all existing options. To do this, you just need to spread the film on the base of the floor. Pour the screed is not needed. Warm floors based on the infrared film, thanks to “dry installation”, can be installed on any surface, including vertical, horizontal and inclined.

To make high -quality electric floor with minimal financial and labor costs, it is necessary to select a coating that strictly corresponds to the needs for the technical characteristics of your home. It is also important that the installation is not complicated for execution on its own.