The chimney is an important part of the boiler equipment that ensures the safe removal of combustion products. He is responsible not only for removing the exhaust gases, but also for the flow of oxygen, without which burning is simply impossible. The market presents a large selection of chimneys for solid fuel boilers from various materials. In this article we will consider which of them are most effective, and also tell you how to make a chimney for a solid fuel boiler with your own hands.

Content

Features of choice

The chimney is an integral part of the heating system. Without it, no boiler will work, no matter what fuel it functions. The main task of the chimney is to withdraw furnace gases and fuel combustion products from the house out. Without it, all the smoke will go into the room, creating a life -threatening situation. The choice and installation of a chimney on a solid fuel boiler is a responsible task in which you need to pay attention to the smallest nuances and have certain knowledge and skills.

The power of traction

One of the main criteria for choosing a chimney is the traction force that it is able to provide. It depends on her how efficiently and rapidly spent gases I will leave the room, as well as the overall performance of heating equipment. The thrust in the chimney pipe is determined by the speed of gases, which are formed as a result of a collision of air flows with different temperatures and atmospheric pressure changes.

The value of traction depends on many factors, but the main ones are the shape of the chimney (the presence of bends and the length) and the section of its pipes. To get the most good traction, the chimney must be straight and narrow to the top. The more bends the pipe, the weaker the craving, since the air requires more effort and time to go from the boiler to the exit. For this reason, when installing a chimney for a solid fuel boiler, you must try to do as few turns, bends and slopes. To do this, heating equipment is best placed in the room from which you can immediately remove the pipe out. Depending on the characteristics of the boiler, it can be a kitchen, a hallway or a separate utility room - a boiler room.

Parameters that determine the efficiency of traction:

- If the chimney is constantly buzzing or periodically begins to make noise, it is recommended to install a special damper (gate) in it. It will help to regulate the strength of traction and will achieve the highest possible.

- If you notice that the furnace gases and smoke gradually penetrate the room, then the chimney has low thrust. Typically, such signs are manifested during the first test. In this case, it is necessary to review the structure of the structure, make it more straight and eliminate possible malfunctions.

- In order to get a stable good traction, the height of the chimney for a solid -fuel boiler should be at least 5 m. At the same time, the pipe that extends out of the roof should rise at least 1 m above the ridge beam.

Features of structures

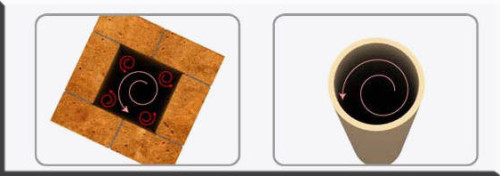

If you are familiar with the basics of physics, then you must know that smoke comes out of the top -bearing compartment of the boiler spiral, and its speed gradually increases. A similar phenomenon necessitates the arrangement of the most direct and vertical chimney. If this is not done, then the path of movement of the smoke will be broken, and the thrust will weaken.

You should also take into account the shape of the cross -section of the pipe for the chimney of a solid fuel boiler. The optimal shape is a circle or an oval. Square and rectangular pipes cannot provide the most efficient removal of furnace gases. In this case, swirls will form, soot, soot, the pipe will be clogged quickly, the thrust will be insufficient. The choice of the shape of the cross -section and the length of the chimney is determined by the heating system, the type of boiler and the features of the building.

Types of chimneys

In any solid fuel boiler, the temperature of the furnace gases can vary from 180 ° C to 500 ° C. Naturally, not every material is able to withstand such extreme conditions, therefore, a special high -strength and temperature -resistant raw materials are used for the manufacture of chimneys.

Varieties of chimneys depending on the material:

- asbestos -cement;

- brick;

- ceramic;

- metal;

- glass.

Each species is characterized by operational characteristics, cost and installation.

Asbestos -cement chimneys

Asbestos-cement pipes were universally used for the construction of chimneys just some 20 years ago, but they were very quickly replaced by more advanced materials. Despite the low cost, such chimneys often could not withstand the high temperature of combustion products and burst.

In addition, asbestos -cement pipes can really be installed only in vertical areas, since it is impossible to bend them. They weigh a lot, and it is quite difficult to cope with the installation of their own forces without the use of large lifting equipment. Another serious drawback is the inability to make absolutely tight joints between the elements. This is considered a gross violation of the rules of operation of chimneys in private houses.

Due to the specific composition of the pipe, condensate is absorbed into its walls, which very quickly destroys it. In other words, although pipes from asbestos cement are cheap, they are very unreliable and it is extremely recommended to use them for chimneys.

Brick chimneys

If you still want to save as much as possible, but not sacrifice quality, you can build a brick chimney. It will cost cheaper than the analogs listed below. It is worth noting that for the installation of such a chimney you can use only a burned fire -resistant brick (red or chamotis). Such a pipe will withstand any high temperatures and even the fire of soot inside.

But if you remember, we said that a good chimney with stably strong traction can only have a round or oval section. It will not work to build such a pipe from bricks - it will be either square or rectangular, which means that the accumulation of soot and twisting cannot be avoided. In addition, the brick itself is very heavy, and taking into account that the length of the chimney should be about 5 m, the load on the foundation will be quite serious. Before choosing your choice on this option, make sure that the foundation of the house will withstand additional weight in several centners. For a heavy brick chimney, it is necessary to build an additional strong reinforced concrete overlap. In general, such work requires professional skills, so it is often trusted by stovers-stone-owners.

The rough surface of the bricks will inevitably accumulate soot, so the chimney will need to be periodically cleaned. In the past, in European countries there was even a special profession of chimney sweeps, since there were brick or stone chimneys in all houses. This profession is still alive, but they resort to the services of chimney sweeps only in cases of strong blockages.

Masonry features:

- The masonry of the chimney should only be performed from complete brick.

- For fixation, use ordinary cement-sand solution.

- The walls of the chimney are laid out in shelter so that their thickness is from 12 cm.

- The dimensions of the chimney and ventilation canal should be multiple of brick dimensions plus the width of vertical seams (section 140x140 mm, 140x200 mm, 140x240 mm, etc.).

- The spent gases should not be too cool in the chimney, so it is better to place it in the masonry of the inner loading wall of the building or attach it to the wall. Those sections of the canal that will pass through unheated rooms, for example, an attic or a pantry, must be wrapped on the outside with non -combustible heat -insulating material (usually it is done with mineral wool).

Brick chimneys are perfect for solid -fuel boilers, since they supply spent gases of high temperature, which does not allow condensate to form. On the contrary, if you build such a chimney for a liquid -fuel, pellet or other boiler, constantly acting in slow combustion mode, then condensate will quickly destroy brickwork.

Modern constructions of the boilers have a fairly low temperature of the outgoing gases, so a brick chimney is more suitable for old models or ordinary firewood furnaces. The outgoing gases are saturated with gray, which, mixing with condensate, forms destructive sulfuric acid. If you notice dark wet spots on the walls of the chimney, then sulfuric acid has already begun to corrode them.

Useful advice: to connect a brick chimney to a boiler with a low temperature of waste gases, a special liner in the form of a metal or ceramic pipe must be inserted into the canal.

Ceramic chimneys

These chimneys can be used for any boilers, including solid fuel, since the pipe material is immune to extremely high temperatures and an aggressive chemical environment. This type of product is considered the most durable and high -quality, as evidenced by its high cost.

Depending on the permissible temperature of the exhaust gases, ceramic chimneys are classified as follows:

- For solid fuel boilers, pipes that can withstand a maximum of 600-650C are suitable. They are resistant to the fire of soot deposits and can be used in a dry state.

- For liquid-fuel and gas boilers, you need to use pipes that withstand a maximum of 400-450C, capable of functioning in a wet state. They have special bounces for condensate.

Important: the peculiarity of the ceramic pipe is that it absorbs condensation, and therefore, during installation, high -quality ventilation of the outer walls should be ensured.

Since the walls of the ceramic chimney are completely smooth and even, soot does not accumulate on them. It is very convenient to clean them, and this will have to be done quite rarely. For assembly, a variety of elements are used: pipes from 60 cm long to 1 m. They are connected to each other by means of shaped parts and special adhesive thermal -resistant mastic.

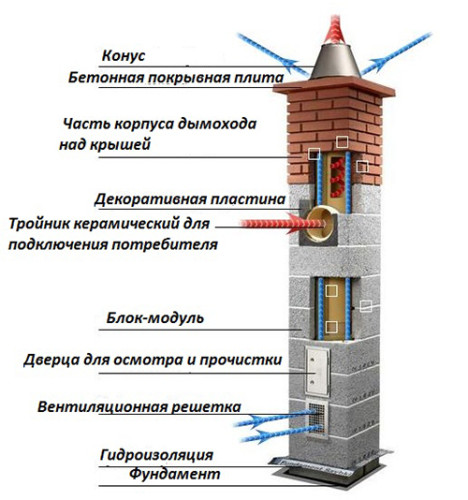

The image below shows a chimney for a solid fuel boiler. It is quite difficult to make such a system with your own hands, so it is better to entrust the work to a specialist. In addition to the ceramic pipe itself, it is necessary to lay the thermal insulation material so that the gases do not cool too quickly and do not provoke the appearance of condensation. You should also build a membrane of concrete modular blocks with ventilation ducts and openings for vertical reinforcement. Ceramic pipes should be placed in special vertical channels, for the construction of which hollow bricks or concrete blocks are taken. The channel itself can be placed in the ventilation unit of the building. In the concrete blocks, in addition to ventilation ducts, there should be holes for installing reinforcement. Part of the pipe protruding over the roof must be reinforced without fail.

The insulation around the pipe is needed not only to prevent too fast cooling of the exhaust gases, but also to protect the surrounding structures from the fire. Mineral wool is best suited as thermal insulation material. It is inexpensive and has the proper temperature resistance.

Metal chimneys

Metal chimneys today are perhaps the most popular mainly due to ease of installation. However, their service life is significantly lower than that of ceramic products, and the cost sometimes exceeds the price of a good brick or ceramic chimney. For the manufacture of pipes, stainless steel is used with a thickness of 0.5 mm, which can withstand the temperature of the gases up to 400-450C and the effect of condensate with gray.

Important: for solid fuel boilers, you should choose pipes made of heat -resistant steel with a thickness of at least 1 mm.

Despite the small period of operation, steel chimneys are in demand, since they are very easy to install, weigh little and do not require strengthening the basis for installing or equipment of ventilations. If necessary, they can easily be replaced or replaced by one of the sections without analyzing the entire structure.

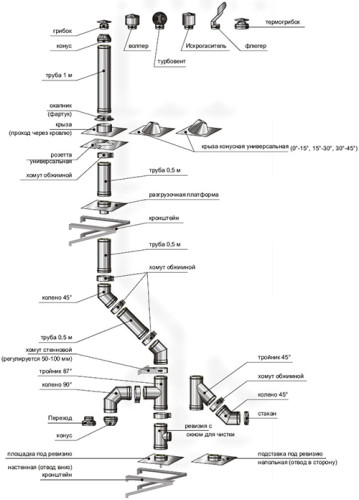

There are several varieties of steel chimneys:

- Single -walled pipes - they can be installed in a specially equipped vertical channel. The design features are the same as that of a ceramic chimney (insulation, ventilation). A single -walled chimney is suitable for the repair of brick and adapt it for a gas boiler. To do this, you just need to insert the pipe into the channel. Such a chimney is quite realistic to make with your own hands from leaf steel.

- Double-walled sandwich pipe is a prefabricated design of finished parts. In fact, one pipe is located inside the other that performs the function of the protective shell. The space between the two pipes is filled with heat -resistant thermal insulation material. For the manufacture of the outer pipe, galvanized steel or stainless steel is used. Such chimneys are very popular, since they can easily be assembled by the type of designer, and can also be installed even in houses where special chimney channels are not provided. Even if you take them to the roof along the outer wall, it will look neat.

- Coaxial chimney - designed for heating equipment with a closed combustion chamber. The design is a pipe placed in another pipe. The internal channel allocates spent gases, and the external supplies oxygen to the boiler to maintain combustion. Due to this effectiveness, the cost of coaxial chimneys is quite high.

Glass chimneys

It is difficult to believe, but the chimney can be made even of glass. It is clear that such an exotic product is unlikely to get at home. Nevertheless, factory glass chimneys are the most effective than all the above analogues. They appeared relatively recently, but immediately demonstrated their exceptional qualities. Since the glass is not at all subject to corrosion, condensate is not afraid of it. It is easy to clean, if you have to do it at all - a smooth glossy surface almost does not accumulate soot or soot.

The glass chimney is the safest and most reliable, but it also has its disadvantages. The main of them is the prohibitive value and a specific setting that requires the presence of a professional. However, in comparison with the advantages, the amount spent on a glass chimney will pay off in a few years.

Installation rules

From everything written above, we can conclude - to know how to make a chimney for a solid fuel boiler, you need to perfectly know the characteristics of the material used, have a clear action plan and the pipe laying scheme from the boiler to the roof. To do such work yourself, and even without proper skills, is almost unrealistic. It is much easier and safer to purchase a finished product in the store and collect it or invite a specialist.

Here are a few recommendations on how to make a chimney for a solid fuel boiler correctly:

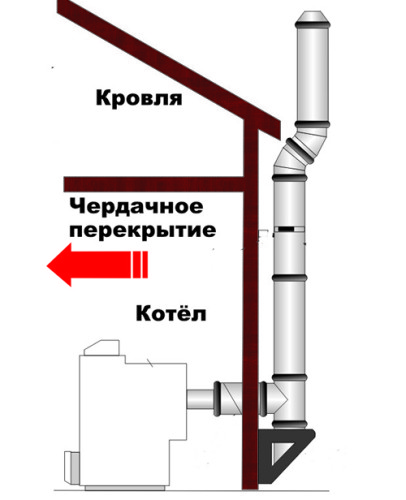

- Always mount the structural elements, moving from below-up.

- If you use tees, bends or other similar elements, fasten them with metal clamps. Make sure that the joints of the joints are outside the ceilings.

- For tees, install brackets for support.

- Every 2 m of the chimney, attach it to the wall, having previously made sure that the pipe does not bend.

- Do not allow the channel to contact with any communications, whether it be a gas pipe, electric wiring, etc.

- When you remove the chimney through the roof or ceilings, withstand a distance of 15 cm between the pipe with insulation and 30 cm - without insulation.

- If you can not do without the creation of a horizontal area when installing the chimney, make sure that its length does not exceed 1 m.

- The diameter of the chimney for a solid fuel boiler should be calculated in accordance with the characteristics of heating equipment (its power), the length of the channel and the features of the building.

- When installing the chimney, take into account the fact that the design can be deformed due to regular temperature loads and differences. So that this does not harm the entire system, install a flexible adapter. If you have not installed it for some reason, attach the pipe to the bracket not too tight-leave a supply of 10-15 mm in case of temperature movements.

- For roofs made of combustible materials, a sparking must be installed on a chimney. It can be bought or made independently from a metal mesh with cells of no more than 5x5 mm.

So that the chimney serves you for a long time and breaks, take it a rule at least once every six months to look inside the pipe, check its condition and clean it if necessary. Finally, we suggest watching a video about chimneys for solid fuel boilers: