Anyone who builds a bathhouse, as a result, always encounters a problem which doors to choose. Of course, you can buy doors to the bathhouse and buy it, but it is quite possible to make it with your own hands, there would be the necessary materials and desire.

Content

Types of doors

The bath and the sauna consist of several rooms, and to isolate each from each other, you need a door. At least there are two of them: the entrance and the one that shares the steam room from the rest room. Ideally, the door still needs to be put in the dressing room and in the washing. There are several types of doors:

- The door is deaf made of wood - it consists of a canvas, which is made of rogue boards with lining. These doors are most often single -line. It is more difficult to make two -preservative doors, only professionals can make them only, but they are remarkably held warmly.

- Doors for a glass bath - they are most often installed in the saunas, but sometimes they are found in baths. Nevertheless, experts believe that they are not suitable for baths. Yes, and buying wooden ones is much cheaper than glass doors for a sauna, which are made from not simple, but from refractory glass. Such a door will not be completely made on your own. Of the advantages - this door fits remarkably into the interior.

- The door is combined - it is suitable for those who like glass doors and wood, because it combines these two material. The bottom of the doors and the frame consists of wood, and the top is made of glass.

Production of a door strapping

Starting work on the construction of a bath door, it must be borne in mind that it will stand in very unfavorable conditions for wood - at high temperature and humidity. And in order to maintain heat, the dimensions of the door must be reduced. The door with dimensions of 550x1650 mm is considered good. For the construction of the door, you will need:

- pine board 0.36x12 cm - for the canvas;

- bay of 6.5x8 cm - for strapping;

- lining 1.2x9.6 cm - for lining.

To make a strapping, you need to perform such actions:

- Using a manual milling cutter, it is necessary to make grooves in bars according to the size of the profile. First, make a draft option and give a 2 mm tolerance to the side, it will be needed for milling for finishing dimensions.

- In length, you need to cut off the horizontal profiles with a hacksaw and in order to dock them with vertical profiles at the two ends, you need to make seats.

- Cut off the vertical strapping profile.

- Collect the frame, finalize the markings and make the grooves with a milling mill already in the final version.

- Collect the frame again, depending that the corners are 90 degrees, and measure the dimensions in the seats with a door leaf under the joint.

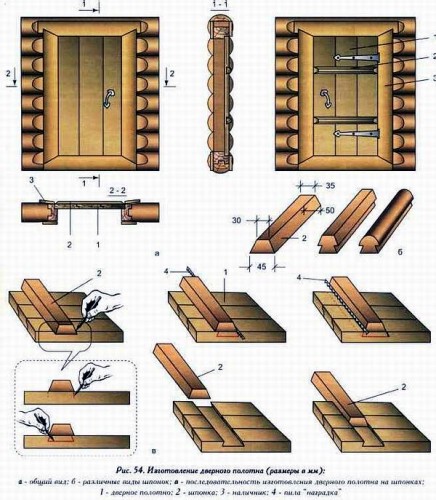

Production of the door leaf

To make a canvas door from wood to a sauna or bath need to perform a number of such actions:

- With the help of a shirt, remove the spike from the extreme plank.

- Put the board on a flat plane, for example, a workbench or table and assemble the canvas together. The canvas will consist of boards and they are assembled on the principle of “spike to the groove”, starting with the first prepared. In the finished form, the assembled canvas needs to be more than the door on the width of about one board.

- With a pencil on the door leaf, make marks from the initial board to the width that is ultimately needed. Leave a small tolerance for finishing processing. The size of the canvas should coincide with the size of the binding frame.

- Cut the last board with a saw along. And you can start the final assembly of the canvas: fix the bar on the table exactly, and collect the canvas on it so that the spike falls into the groove. Before that, the spike and the groove are treated with PVA glue.

- After installing the last board, it is necessary to fix the supporting bars to the table. And squeeze the boards to each other with wooden wedges. In order for the plane to remain even, you need to put an even sheet of chipboard on it and squeeze with clamps.

- When the glue dries, you need to check the build quality. If the gaps are visible, then they need to be carefully sealed with sawdust mixed with glue. Using a rubbish and sandpaper, remove all the irregularities from the canvas.

- Now you need to draw the necessary dimensions on the canvas, you need to build on the outer edge of the extreme board and ends, which are connected to the supporting bar.

- Cut the marking canvas with a circular saw, and grind the edges with a skin.

- Make a symmetrical veneer around the perimeter. Using a milling cutter and basic planks, fix the processed side of the door. The strips are installed so that their edges lie in the vertical plane. And the upper faces should be in the same parallel with the canvas and serve as a support for the milling cutter.

- After processing one side, all the same manipulations must be carried out on the other hand. Only the width of the spike should be slightly larger so that when landing in the strapping it can be finalized.

Lining the canvas lining

The sheathing of the canvas can be made in different options. Sometimes during the installation of a strapping, and sometimes in this way:

- The harvesting of the lining must be taken longer than the line that passes at an angle of 45 degrees from one side of the canvas to the other. The workpiece is attached to the canvas with self -tapping screws. Gradually cover the entire canvas with boards of the lining.

- On the skin, outline the circuit so that the cut ends are hidden, and the strapping and the lining do not interfere with each other.

- On top down each lining, then disassemble and cut along the intended lines with a hacksaw. Repeat the technology on the back of the canvas.

- Cut the cut blanks are put in place, each element is attached to the canvas with three screws at an angle of 45 degrees.

- Fix the extreme boards on top with the help of self -tapping screws so that the heads are not visible under the strapping. And so that a crack does not appear in the groove, it must be sprinkled half a million more than the diameter of the screw itself.

Assembly of the door for a bathhouse

The assembly of wooden doors for the bath consists of installing a strapping around the canvas:

- From all sides, you need to insert already prepared blanks into the spikes of the canvases, this must be done without a gap and with a slight tension. If necessary, it is necessary to mill or spike, or groove. The main thing is that there is no lumen between them.

- Check the assembly quality and start the last stage: process all the docking places with PVA glue and fix the strapping with self -tapping screws. Self -tapping screws should not interfere with the installation of door loops, so they need to be tightly cut into the canvas and withstand a step of 20 cm. Next, you need to fasten all the elements of the strapping in the corners.

- In order to make it possible to disassemble the door for repair, you do not need to glue the lower profile at the strapping.

For the finish processing of the door, an abrasive skin will be needed, its grain should have both middle and small. It is necessary to walk especially carefully in the corners, remove all the irregularities on the plane, and round the sharp areas. As a result, the door should turn out to be smooth and pleasant to the touch. The edges can be treated with special cutters on a manual milling mill. Now the door can be decorated with your liking rails or strips. When the door will be installed in the doorway, then the pen can already be attached in place.

Useful tips

- There are many variations for lining for lining the door, it all depends on the design of your bathhouse. You can arrange it horizontally or a Christmas tree, or a combined method. Based on how to skin the door, maybe it will be necessary to install several more decorative strips on the end parts of the lining.

- In the collected form, the sex boards usually have small longitudinal gaps located on the back. Thanks to them, it is possible to tightly fit the boards so that there is no gap on the front surface. To eliminate these weaknesses, you need to pour sawdust with glue into the gaps.

- For the manufacture of the door, take the wood of one tree breed. Well suited for this linden or black alder. This is necessary so that when heating or a sharp temperature difference occurs, the door does not deform. Because different wood breeds react differently to such adverse circumstances. If, for example, the door leaf consists of pine, and all the other elements of linden, but it is closed with a sheathing, and the steam does not cause damage to it directly, then you can not pay attention to such a difference in rocks.

- The quality of the material should be treated with all seriousness, if you take lumber, then they should not have any obvious defects or through knots. You can allow them to have in the doorbell for the bath and then, only due to the fact that it is closed with a sheathing.

- If you have nowhere to buy downtings or not, you can connect them on a quadricular sample, you can do this using a hand cutter.

- If you do not have any tools such as a disk saw or milling cutter, then they can successfully replace a chisel and a hacksaw. True, it will have to turn longer with the materials. Therefore, if you have already decided to build such a design as the steam room and make the door to the bath with your own hands, it is better to get good electrical tools so that you do not waste your efforts and time.

- In order for the door to serve as long as possible, you need to treat it with olifa or other good antiseptic. Particular attention should be paid to the lower part of the door, because the door, as a rule, begins to collapse from below.