There is no better way to refresh yourself on hot days than to take a shower. In the country for this purpose, you can put showers of polycarbonate. Why should this particular building material be used? We will tell further.

Content

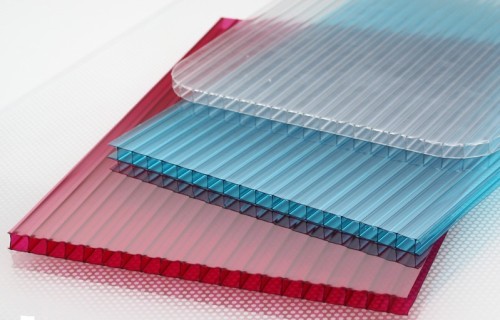

Characteristics of the material

Polycarbonate is a polymer plastic with a unique texture, made by extrusion of granules. This technology for the production of material makes it possible to preserve its unchanged dimensions. It is possible to melt this type of plastic, after which you can give it a new shape. Other advantages include the following:

- The material can withstand temperature drops from -35 to +110 degrees.

- Polycarbonate has high plasticity, which allows you to create buildings of almost any geometric shape.

- The material has a low weight. Therefore, even one can work with him even one.

- Reliable sound and thermal insulation.

- This is a very strong material, so it is difficult to break and it is able to withstand heavy loads.

- This type of plastic due to resistance to cleaning agents and chemistry is easily cleaned.

- Environmentally friendly material.

How to make a shower of a polycarbonate cabin

Choosing a place of accommodation

If you decide to install a shower in your area, then the first thing you need to decide is the type of structure. So, you can build a simple summer shower with an ordinary tank, and it is possible to make a more fundamental and complex construction with heating. Whatever the design is chosen, you need to rationally choose a place to accommodate the future shower. In order to do this correctly, there are some recommendations:

- So, the place should be chosen protected from strong winds.

- So that in the future there were no problems with how to remove stock water, the place for the booth should be on a hill.

- In addition, the shower cabin should be in the world as long as possible during the day. At the same time, it is desirable that he is hidden from prying eyes.

- In addition, the place for the summer shower made of polycarbonate should be quite spacious. You also need to provide a free supply of electricians.

Preparatory work

Plum for stock water can be made differently: it can be a recess, drainage, compost pit or septic tank. Drainage and septic tank is not recommended due to an unpleasant odor that appears over time. When the optimal place for the shower cabin is found, you can begin to design important building nuances.

To facilitate the task, it is recommended to make a drawing of a shower cabin in advance, which you want to construct. The scheme should indicate the main sizes and location of the building in your site. The finished drawing, in particular, will accelerate the construction of the frame on which polycarbonate panels will be attached, as well as a shower tank. This design must be done with the calculation of the weight of the panels, the tank and the amount of water that can fit in it.

As a material for the frame, it is recommended to use pipes with a size of 60 × 40 mm. Intermediate shower compounds for giving polycarbonate can be made of smaller pipes.

Elements of the frame can be:

- Vertical racks in size 2.3 m - 6 pcs.

- Horizontal supports measuring 1.5 m - 6 pcs.

- Side horizontal supports with a size of 1.2 m - 4 pieces.

- Spit supports of 2.35 m - 4 pcs.

- Spit supports of 2.5 m - 2 pieces.

Selection of profile

The profile, in fact, is called a frame on which polycarbonate sheets are attached. Depending on what the owner wants to eventually receive, as well as on some other factors, different materials can be used for the manufacture of the profile:

- It can be steel, which is highly resistant to corrosion and strength.

- The profile can be made of PVC, if practicality, low weight and sound insulation are important. In addition, light and high -plastic aluminum can be used as a material for the profile. This material is chosen if the durability of the frame is important.

- The frame is often made of wood. This material provides ample opportunities in terms of processing. At the same time, it is environmentally friendly.

- Available replacement for natural materials for the profile is MDF. It tolerates low temperatures and exposure to sunlight well.

Stages of construction of the structure

Procedure for the performance of work:

- After completing the preparation of the frame, you can do the foundation in which the drain must be provided. After that, racks are installed. The first to dig the supports vertically into the ground to a depth of about 500 mm. It is advisable to fix these racks with concrete. If the frame is made of wood, then special antiseptics should be applied to the ends going to the ground, which will prevent decay. In addition, wooden racks are recommended to be wrapped in roofing material.

- When the vertical racks are installed, you can do horizontal. The vertical supports should be fixed step by step on horizontal. This is done in different ways. So, for example, this can be done by welding, when attached with bolts, corners or use special couplings.

- To strengthen the design, in addition to vertical and horizontal racks, it is also necessary to use oblique supports. This will allow the shower booth from polycarbonate to be more resistant to wind and other weather phenomena. In addition, this will help withstand the weight of the tank filled with water.

- Now you need to do the roof. In this case, you need to carefully follow the instructions attached to the materials.

- The next step will be the tank installation. It is usually placed in the center of the roof and at the same time its weight should be evenly distributed to all supports of the case. Moreover, the easier the frame, the less the volume of the tank should be. It is advisable to fix it by welding or use special brackets for this purpose.

- The fasteners for the tank should be provided in the overlap of the structure. It is important that the overlap can withstand the weight of the full tank. In addition, you need to tightly bind the overlap and anchors, embedded in brickwork.

- To reduce the time of heating of water in the tank, you can make a simple structure from the racks and polyethylene, i.e. Something like a greenhouse. Due to which it is possible to heat the water by 7-11 degrees. The water heater will heat up the water even faster.

- For the tank, it is advisable to provide a float to know the water level in it. In addition, it helps to make a fence of warm water on top. The same will allow you to heat the cold fluid located at the bottom of the tank by moving water. This is especially true in the last months of summer or on cloudy days, when the sun cannot properly heat the tank.

- As for the tank itself, it is best to use flat models. The advantage of such containers is that the water in them heats up faster. In addition, they are usually more stable. After installation, a flat tank will make a home -made shower of polycarbonate not much higher, so the shower will stand firmly on the ground.

- Then you need to fix the polycarbonate panels on the frame. Their width must be 85-170 mm. Moreover, it is better to get transparent for the roof, and matte panels for walls. When installing sheets using profiles and aluminum tape, it is necessary to completely isolate the air channels. For this purpose, you can use a transparent sealant. If the air channels are not isolated, then the surface will gradually change its color and lose its appearance.

How to choose fittings

When creating a shower from polycarbonate, an important stage is the choice of components. When installing the partitions, in order to qualitatively perform all the necessary work, the following additional materials are needed: fasteners, profiles, thermo -shabes, sealing tape, as well as a seal.

Thermal -haired ones will serve not only for attaching and sealing parts, as well as as a thermal expansion of the material. Sealing tapes are needed in order to protect the ends of the structure from dust and humidity from the environment, and this, in turn, increases its life. As for the seals, their task is to ensure the tightness of all compounds and the provision of temperature expansion material.

What the cost of the design depends on

Prices for polycarbonate signs for the shower depend on several important parameters. The following indicators are taken into account:

- The required number of components.

- Design option.

- The size of the booth.

- The complexity of manufacture and further installation.

- Type of material and the amount of its layers.

- Use and type of decorative design.

- The quality and thickness of the facing sheets.

Due to the fact that shower partitions are usually made according to individual sizes, the cost for each case is usually its own. So, for example, if you do not take into account the upper guide, the price of materials for a booth with an area of \u200b\u200b1 sq.m. It will be from about 2100 to 3200 rubles. Cabin area with an area of \u200b\u200b2 sq.m. It will cost 2600-3950 rubles. If it is also planned to set the guide, then the total price should be added to the amount equal to 135 rubles per meter of material.

Operation Rules

One of the important advantages of showers from cellular polycarbonate is that they do not require any special care. Most contaminants are easily washed off using a jet of pure water. Nevertheless, there are still some recommendations for operation and care.

- So, you should not rub the panels intensely with a rag. The fact is that this can cause scratches, which, in turn, lead to the destruction of the material, and therefore the integrity of the booth.

- If you want to use any special tools for cleaning, then you should first make sure that they do not have substances that can destroy polycarbonate panels. This information is usually on the package.

Polycarbonate showers today are the most practical, modern and profitable ways to create a place to take a shower in a summer cottage. It is important that such a design can be built without much difficulty with your own hands. To do this, follow the instructions and recommendations. If everything is done correctly, then the shower will be able to serve you for many years. It is impossible to note the attractive appearance of the material itself, due to which showers can easily ennoble the garden area.