A cutting board is an integral improvised accessory in the kitchen of any housewife. It is used mainly for cutting vegetables and cutting meat. Separate types are made for serving, as a stand for hot dishes and for serving dishes to the table.

Content

Types of cutting boards made of wood

Souvenir, varnish -covered cutting boards are designed to decorate the walls in the kitchen. However, modern masters began to make such accessories with the possibility of their further use in everyday life. One side of the souvenir board is decorated with carvings and ornaments, and the other is a clean tree.

It is traditionally believed that the shape of the cutting board should be square or rectangular, but today it can be acquired completely different types: oval, round, reminiscent of an apple, fish and so on.

In order not to tiring not to look for a cutting board suitable for you in stores, it can be made independently to your taste.

To cut meat, it is recommended to use dense and heavy boards. For cutting vegetables and greens - small mobile and multifunctional. In your kitchen, it is better to have a complete set of boards of different sizes and purpose. According to the classification, the boards are divided into such types: cutting, decorative, decoupage and carved.

- End boards. They are most popular for cutting meat. On such a board you can prepare chop or antrakot. The board is able to withstand the blows with a chopping hammer. The oak end board is particularly durable and the tip of the knives is much less stupid, unlike ordinary boards.

- A cutting board from an array of beech, pine, birch and bamboo.

The most budget option is a pine board. Such a board is easy to process and has low hardness.

Birch and beech boards win in quality due to their hardness and strength. But their minus is excessive hygroscopicity. Moisture acts on such boards destructively.

A Chinese -made bamboo cutting board is less popular, but its cost is much less than the price of oak or birch.

Raw materials for the manufacture of cutting boards

Before making a cut board with your own hands, you need to choose the material. For these purposes, raw materials of wood, silicone, plastic, stone and glass ceramics are used.

- Tree. In a household, you can most often see beech, oak or pine cutting surfaces. It should be noted that such surfaces are suitable only for cutting bread or dry vegetables, since a tree of the above varieties is quickly destroyed under the influence of moisture.

Bamboo kitchen boards are characterized by high strength and resistance to pressure. Moisture -resistant, perfectly wash and do not absorb food smells.

Clothing boards from acacia and oak - the choice of professionals. Their advantages are high quality. The disadvantage is high cost.

Care. A wooden cutting board cannot be washed in a dishwasher. It should be rinsed under the tap, but do not soak in the sink. Once a week, the tree must be wiped with vinegar essence to get rid of microbes.

- Stone. Marble, granite and stone cutting surfaces look very spectacular. Marble has bactericidal properties, does not tolerate too hot objects on its surface and treated with acid -containing substances.

The kitchen board made of stone is ideal for rolling the dough, which turns out on it evenly thin.

Care. The stone surface must be periodically cleaned of blockage, since this material should “breathe”. With proper operation, cutting boards made of stone are able to last a long time.

Plastic. In this case, it is necessary to choose exclusively high -quality plastic, which has heat -resistant and moisture resistant properties. A good plastic board is more durable and hygienic. If you are going to make a plastic board yourself, then choose a colorless material that does not contain toxic substances.

Care. Plastic can be washed in a dishwasher. After cutting meat or fish, a plastic board should be washed with a liquid for dishes. And for disinfection, you can place it for 2 minutes in a microwave oven along with a glass of water.

- Silicon. Kitchen cutting surfaces from silicone have long gained their popularity in the kitchen utensil market. Silicon does not slip on the surface of the table, does not absorb smells from the products and does not dull the tip of the knife. It is convenient to store it in a folded form. The silicone rug in its functions does not differ from the traditional wooden board.

Care. Wash a silicone rug with a detergent without acid content. Its immersion in the dishwasher is also permissible. This material withstands both high and low temperatures.

- Glass ceramics. A cutting board of this material is durable and resistant to shock. It is easy to wash, withstands the effects of high temperatures and does not absorb grocery smells at all. For use in a kitchen, this is not a very practical option, since the knife is quickly stupid on the glass surface. A glass -ceramic board is ideal as a decoration of the kitchen interior and a hot stand.

Care. It is subject to washing in a dishwasher.

What the traditional cutting boards look like, you can see in the photo below.

Design of cutting boards

The design of the cutting board can be very diverse. If you are in search of unusual forms - take a note of several design solutions.

- Classic wooden board with flow for liquid, metal edging and a knife place.

- Putting cutting board. It is attached to the closet and extended from it if necessary.

- Rectangular board with removable plates. When the products are cut, it is enough to shift them with a knife into one of the plates.

- There are also cutting boards with drawback containers for cleaning and garbage.

It will be somewhat more difficult to make one of these cutting boards with your own hands than ordinary. But if there is desire and knowledge, you can make such a design version.

DIY wooden cutting board

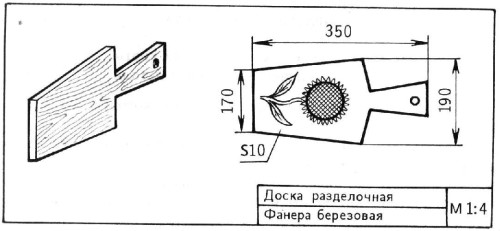

A cutting board from plywood is a more traditional option. It is practical and convenient to use in the kitchen. In our case, the technology for manufacturing boards from birch plywood is presented.

For work, you will need:

- pencil;

- sample;

- workbench and hacksaw;

- drill;

- drill;

- file;

- vise.

Before starting the creation of a kitchen accessory, it is necessary to sketch a drawing of a cutting board.

- Prepare a birch board with a thickness of 12 mm and carefully mark the contours of the boards on the template on it with a pencil.

- Using a hacksaw, cut the product along the contour.

- On the board with an awl, mark the place for the hole and drill it with a drill.

- Click the product in a vice and file cleaning its surface. The edges are a little round.

- If desired, you can decorate the outer side of the board with watercolor paints and cover it with varnish.

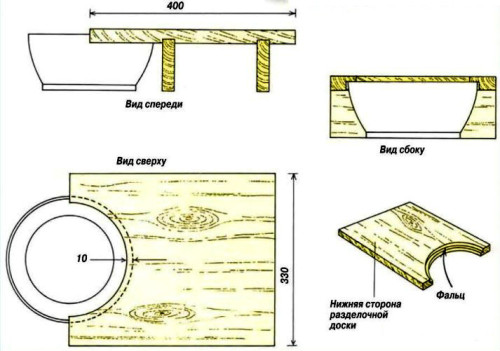

Cutting board on supports

It will not be difficult to make a cutting board with your own hands. However, it will be a little more difficult to make its design with supports and a recess for a plate. According to the presented drawing, you can clearly imagine the design of the future cutting board.

For work, you will need:

- blanks made of oak for a shield (40x33x3 cm);

- 2 boards from oak for supports (10x33x3 cm);

- pVA glue;

- varnish;

- sandpaper.

The dimensions of a homemade cutting board are designed for a plate with a diameter of 25 cm and about 10 cm high. You can use the sizes provided, or you can create a board for such a plate that will be convenient for you to use in the future.

- Three strict plates from oak glue together in a shield.

- When the shield dries out of it, it is necessary to cut the blank for the board. Length 40 cm, width - 33 cm.

- From one edge of the workpiece with a pencil and a circul, it is necessary to draw a semicircle. You can use the appropriate plate instead of a circul. After 10 mm from the dashed line in parallel, draw a smaller semicircle to it. This is shown in the figure above.

- Drink a smaller smaller jigsaw.

- On the back of the board, place places for the supports and cut them off with a carpentry chisel. Get the support cut from the oak into the resulting grooves.

- Grind the surface of the cutting board carefully with sandpaper.

- First, soak the tree with olive oil, and then - varnish everything except the working surface of the board.

A cutting board from an oak with supports and a notch for a bowl is ready. When the varnish dries, you can start using the board.

In order for the cutting surface to not keep the smell of fish in itself - lubricate the tree with a half of the lemon and rinse with hot water. Cutting meat, cutting vegetables and bread on one board is not recommended. For each purpose, you must use a specific purpose board.

You can see in detail about how to make a cutting board at home.