A comfortable small sofa will decorate and create comfort in your kitchen. You can not always choose a suitable sofa for the kitchen in a furniture store to taste or dimensions. But there is a way out - to make a suitable sofa with your own hands.

Content

A little skill, imagination and a minimum of costs are all that you need to create your own individual intimate corner in the kitchen. This is especially true for a small kitchen, in which standard sofas are not suitable.

Advantages of the kitchen sofa

- The advantage of such a solution is that you can get a kitchen sofa of the necessary dimensions corresponding to the interior upholstery and significantly cheaper than the finished sofa in a furniture store.

- Moreover, you can show creative imagination and your own kitchen sofa will be distinguished by originality and individual design details. The ideas of an acceptable version of the sofa for the kitchen can be spied on the photo on the Internet.

- In its design, the sofa for the kitchen is not complicated. Two sides of laminated chipboard and a reliable frame of boards, timber and fiberboard. For upholstery you will need foam rubber, lamb or leatherette. The great advantage of the kitchen sofa made by yourself is that it will last much longer than purchased in the store.

- Pay special attention to the upholstery. In the kitchen, especially small on the sofa, evaporation is precipitated during cooking. Choose as an external coating - easily cleaning material.

Preparatory work

Materials and tools

For work on the manufacture and assembly of a mini sofa for the kitchen, you will need:

- Laminated chipboard for the sidewalls, back and seat. Choose sizes in accordance with the dimensions of the sofa.

- Brick with a section of 4x4 for the frame base of the sofa.

- Plywood 8 - 10 mm thick.

- Foamen from 5 cm thick.

- Landing material (leatherette, lamb or other)

- Screws and confirmation (euro -voins), bolts with nuts and washers of 8 mm diameter.

- Royal loop for hinged seats.

From the tools you must have -

- Electric, drill, knife on wood, screwdriver.

- Construction Stapler.

- Rashpil, sandpaper, roulette.

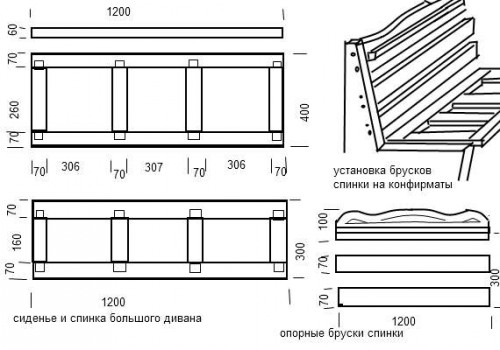

Drawing - scheme and cutting blanks

- First you need to sketch the drawing indicating all sizes. If you plan to make sides from a solid chipboard, then you can draw them on a large sheet of paper, in full size and transferred to the pattern to the cutting out surface of the chipboard.

- Options for drawings and schemes of small sofas for the kitchen can be found in the photo on the Internet. Dimensions in length and height are adjusted taking into account the characteristics of your kitchen. It is practical to provide a folding seat under which there will be a box for kitchen utensils.

Step -by -step instructions for assembling a small sofa for the kitchen

- The main frame is assembled from the 4x4 beam. Conditionally, the length can be taken 1200 mm, a height of 480 mm and a seat width of 400 mm. The front and the back are sewn up with plywood. The bottom is also made from plywood, but for its fastening, the grooves are selected in advance or the fastening on the corners is provided.

- The frame is fastened with screws, stiffeners are added and the structure is fixed in the corners.

- The upper cover is cut out by an electrician from a sheet of chipboard at least 20 mm and is attached to the piano loop and the base of the back.

- The sides are cut along the pattern. They can be continuous or combined. This work is done by an electrician. All processed end surfaces are polished by rashpil and sandpaper. They are decorated with a special end ribbon. There is a large selection of endings of different width and color. As a rule, they are self -adhesive, but you can use PVA glue.

- The sidewalls are securely attached to the frame with bolts or confirmation. In places provided for the back, the design is pulled out by two bars.

- The back is also cut out of a whole sheet of chipboard with a thickness of at least 20 mm and is attached to bars. The kitchen corner consists of three parts. Two straight sofas - long and short and small corner connecting banquet. The principle of their manufacture is similar to the above.

Control of the surface of the sofa for the kitchen

- Foam is cut out for each part separately according to the specified sizes. The processed surfaces for better adhesion are treated with sandpaper and foam is glued on them.

- For the back and seating, an overlapping end of the end is made, about 20 mm and is fixed with a stapler.

- From the selected upholstery material, patterns are cut along the contour of the processed surface. For kitchen corners, different coatings are used. Barakan, velor, skin or its substitute, etc. But it is necessary to provide the opportunity to easily and efficiently clean the sofa. So in terms of hygiene, it is better to use leather -aligned coating.

- Ready -made patterns are attached with a stapler with a step of 20 mm.

- In the corners of the bottom or in the lower part of the sidewalls, the legs are placed. It is better to buy them ready -made furniture fittings. For a small sofa for the kitchen, the price of such legs is very low.

- The final bar for a narrow sofa for the kitchen will install armrests. To do this, in cutting bars with a section of 4x4 cm, a longitudinal sample of the groove is made with a width of 20 mm and a depth of 25 - 30 mm. So that the bar of the armrest sat on the side of the sidewalk. The sample can be made by a chisel or chisel, but it is better to be protected in the carpentry workshop.

- The armrests can be shut up with foam rubber and covered with a tanner or covered with stain and varnish. The armrests sit on glue and are additionally fixed with screws.

- All visible heads of screws and confirmation are decorated with special plastic furniture plugs.