The birth of children in each family is considered the most important event in life. It is they who are what we live for, and those people who at the sunset of our lives will become us hope and support. It is not sacred that each of the parents tries to make the life of his child as comfortable as possible. When the child begins to sit, he will need a place for which he can eat and play.

Content

Currently, there are a large number of different children's chairs on sale. Made of plastic and wood, with a table for or without feeding, a variety of models can be introduced into the difficulty of any adult. However, it is worth noting that the prices of children's chairs are also distinguished by their diversity, and in most cases they can be called democratic with a stretch. And this parameter for parents with a small child is largely decisive. In this case, there is one correct way out - make a children's chair yourself. With little knowledge and experience in the processes of working with a tree, this task will become “on the shoulder”. It is very easy to get materials for the manufacture of a children's chair. Both wood and fasteners can either be found in your garage, or inexpensively buy in any construction store. So, how to make a children's chair with your own hands - further.

Wooden chair: drawing

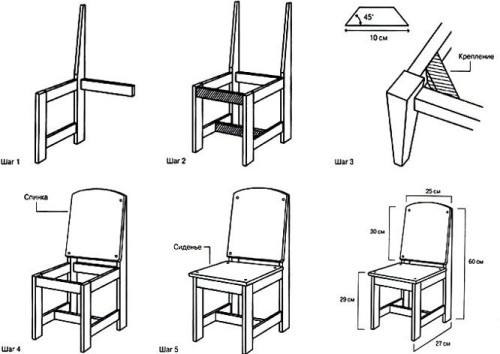

Before starting work, it is necessary to prepare a drawing of the future product. Due to which you can correctly assess the required amount of materials, the sequence of work, the appearance of the future product.

One of the simplest ways to prepare the drawing is a “copy from nature”. To do this, you can take the finished product, and, armed with a caliper, roulette and ruler, remove dimensions from it. After that, just transfer the results to the drawing. If there are design knowledge, then you can experiment and create a children's chair with your own hands, which will be an exclusive product.

Whatever the drawing option is chosen, it must be remembered that this piece of furniture is intended specifically for the child. Therefore, the product, first of all, should be safe. The stool should have excellent stability. A small child is constantly trying to know the world around him, he turns, tries to get to the toy. At this time, the center of gravity of the chair is constantly shifting, so the child can easily fall and get hurt. The chair should not have sharp corners, all metal parts should be hidden in the hid.

For very young people, it is better to provide a small table so that they can eat. If the child is fidgeted, seat belts can be included in the project.

What to make a children's chair with your own hands

Naturally, the quality of the material from which you can make a children's chair with your own hands depends on the monetary capabilities of the parents. If funds allow, it is better to use an array of high -quality wood. With their lack, the chair can be made their plywood and chipboard. Such models, although they do not look attractive, but their cost is much lower.

When choosing an array of wood, it is better to give preference to deciduous breeds. The best choice for the manufacture of furniture is Beech. It has an average density and is quite easily processed, unlike oak. At the same time, the beech wood looks attractive and serves for a long time. The only drawback of this tree breed is the price, although it, of course, is less than that of oak. With a lack of funds, you can use birch wood.

Plywood is another rather popular material for the manufacture of children's furniture. Due to its multi -layer structure, this material has a fairly large margin of strength. At the same time, using the end -to -end technique, you can make a rather interesting interior item. As a rule, chairs made of plywood are painted.

DSP is one of the cheapest manufacturing options. It is simply processed, it is inexpensive, has a sufficient margin of strength. Of the shortcomings of the chipboard, it is worth noting not a very neat appearance, and the fact that the material has not a dense structure. That is why it poorly holds metal fasteners, which can lead to the destruction of the entire structure. Usually, flat was made from chipboard, such as seats or tables for feeding.

Preparation of material and tool

To start work, it is necessary to prepare the required amount of material and fasteners. For the manufacture of simple stools, you will need a certain tool.

The material will be required:

- A wooden bar with a size of 50x50 mm for the construction of the frame.

- The bar 20x40 for installation of the crossbars and the ribs of stiffness.

- A board 30 mm wide and 10 mm thick, or a piece of array or plywood for making sitting.

- Metal corners. If the design is connected using fastening elements, and not using spikes, it must be strengthened with metal corners. They are placed in places of perpendicular compounds and fasten two parts, increasing reliability.

When choosing a tree, it is necessary to pay attention to ensuring that it does not have knots. The knot reduces the strength of wooden elements, and a consequence of which they often break when exposed to loads. In the case of a children's chair, this can lead to a child’s fall and injuries.

From the tool you will definitely need:

- Kryuzovka on wood or electrician.

- Plane.

- Electric drill, screwdriver.

- Electrof -resour, in the event that it is planned to fasten on a “spike”. If the design is mounted by metal fasteners, this tool is not necessary.

- Grinding and sandpaper for polishing the surface of wooden parts.

- Ruler, square, roulette.

Before work, wooden parts must be treated with a shirt so that they have the same smooth surface.

The stool for the child will have the following sizes:

- The height from the end of the back to the floor is 630 mm (a rather high children's wooden chair).

- The distance between the legs of the chair in depth is 280 mm, in width - 320 mm.

- The height of the legs: the front - 410 mm, the rear - 630 mm.

- For the legs of a chair and handrails, a bar with a cross section of 20x35 mm will be used, for transverse mount - a beam of 20x20 mm.

- The connection of elements will be made using self -tapping screws and round spikes.

The process of manufacturing a child of wooden wooden stool

Work order:

- First of all, it is necessary to cut four legs from a beam with a cross -section of 20x35 mm: 2 410 mm long, two lengths - 630 mm. To connect them, we cut out 4 strips from a beam of the same cross -sectional length 280 mm. They will play the role of handrails and ribs of stiffness.

- Next, connect two pairs of legs (long back and short front) using side planks. We do this with spikes. They have a standard diameter of 8 to 10 mm. To do this, holes are drilled in the legs and transverse planks, into the spike. Before scoring it, it is necessary to pour a little glue into the holes. The holes should be 0.5 mm less in diameter than the spike itself, so that it enters them tightly.

- We connect two legs with crossbars at a height of 410 mm and 250 mm (this will be the height of the seat mount). Having collected the left pair of legs, it is necessary to proceed to the right. She gathers in the same way as the previous one. The locations of the legs with crossbars are enhanced by the corners.

- When the process is finished, we apply both halves to each other. They must definitely match. Otherwise, the chair will be uneven.

- Next, connect both halves using bars with a section of 20x20 mm and 310 mm long. To do this, in the crossbars we drill holes with a diameter of 8 mm and screw into it a self -tapping screw with an internal hexagonal hole in the head. Having installed these bars, we get a design that is already completely similar to a chair. The final appearance will betray the installation of the back and seat.

- We make the back from several small planks 10 mm thick and 30 mm wide. We beat them to long legs using small nails. In this case, the back from the planks will play the role of additional stiffness. Exactly, like the seating that is collected with the help of the same planks.

- After collecting all the elements, the design of a children's wooden stool is ready. One of the strengths of this design is that on top of the side handrails you can easily install a small table for feeding. For its manufacture, a sufficiently small piece of laminated chipboard with a thickness of 20 mm and PFH edges.

- DSP must be cut out (the shape and size depends on the preferences of the parents) and close the place of the cut with an edge of PVC. Then it is necessary to make two through holes in the places where the table is attached to the handrails and fasten it to the chair. Now the child will be able to play, sitting in a chair, or eat. If you are afraid that the child, especially small, can fall out of the chair, you can attach him a “safety belt”.

- Connect the bottom of the table and the lower part of the seat with a piece of the old leather belt. The belt to the tree is screwed with self -tapping screws with large washers. Now, this belt will be in the child between the legs and will not let him slip off the chair.

The last stage in the manufacture of a children's wooden chair with your own hands will be its processing and painting. The fact is that the child will do anything with his chair, and he should endure this test with honor without injuring the baby. All sharp corners and burrs must be treated with sandpaper. To protect the tree from corrosion, it must be opened with several layers of olifa and painted. When choosing paint, give preference to wear -resistant materials that will not exfoliate, because pieces of paint can not only cause a child’s injury, but can also be eaten by it. After painting, you can apply a layer of colorless varnish.