Today, parents are increasingly making interior items for their children personally, without resorting to the help of specialists. Moreover, it is not only simple furniture (stools, chairs), but also more complicated, among which the sofas, beds and others are included. Make a bunk bed with your own hands - not a very difficult task, to cope with which a person may not even have an initial Carpenter skills. It is enough just to properly adhere to the size and technology of the assembly, prescribed on the schematic drawings of the product. How to make a bunk children's bed with your own hands - let's tell later in the article.

Content

Children's bunk bed. Characteristics of construction

Advantages of bunk design:

- In small-sized apartments, quite often resort to the manufacture of bunk beds for children, because such structures significantly save the useful area of \u200b\u200bthe room.

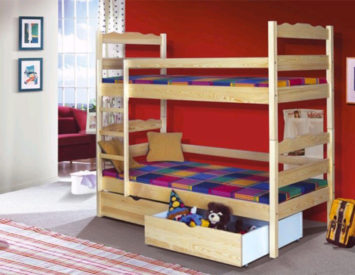

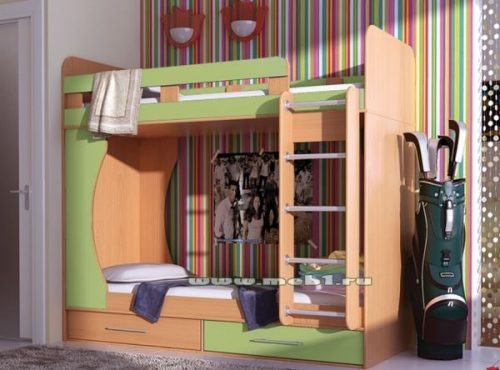

- In addition, such products today have become popular even in large homes, because they look pretty original and make a children's room more interesting and stylish.

- The bunk design is quite functional, because it does not necessarily do a double, but you can install a children's desk or chest instead of a second bed.

- Such beds are very familiar with children, since the kids will be interested to sleep "on the second floor."

If you have sufficient financial resources, you can purchase such a bed in the furniture store or in order to save it. In addition to reducing estimates, manufacturing the bed on their own, you can build exactly the construction that will be perfectly fit into the children's room and meet all the requirements entrusted to it.

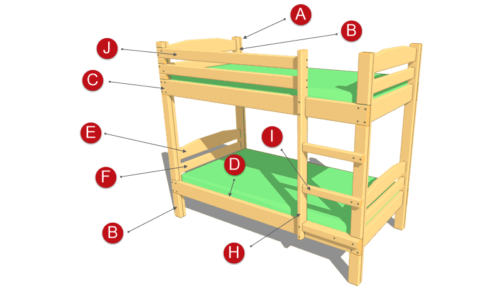

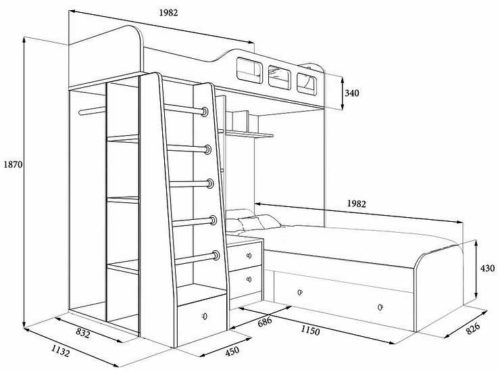

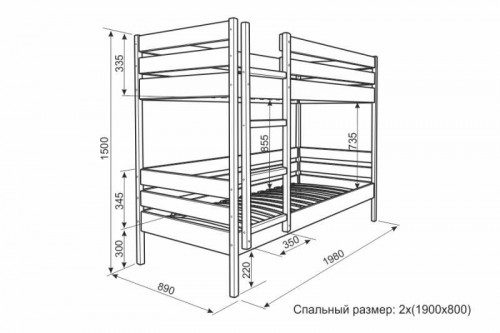

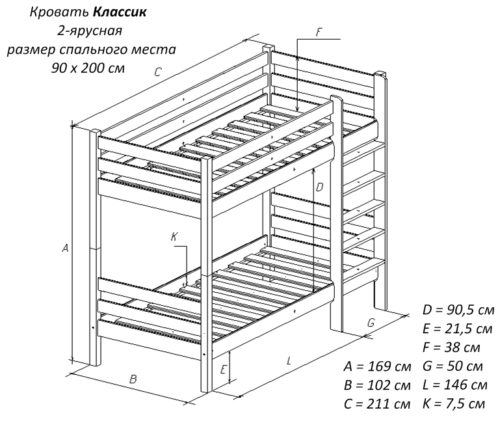

Children's bunk bed do it yourself: drawings

The first stage in the construction of beds for children is planning and design. Here the necessary dimensions of the future design are determined, and an approximate estimate of the cost of installation work is also compiled.

At this stage, determine the following:

- Place for bed location. It should be chosen based on the planning of the children's room.

- Options for the location of the staircase for lifting to the second tier. It is usually placed on the side of the facade (that is, on the right side of the bed).

- Sizes and shape of sleeping places. In addition, their number is determined, because, as already mentioned above, a written table or chest of drawers can be made on the first tier.

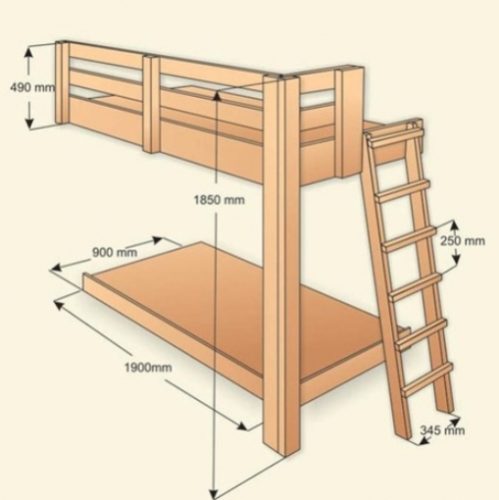

- Height and width of the product. Note that building the second tier is too highly strictly prohibited for security purposes. The width of the beds should depend on the size of the children's mattress and the growth of children. Approximately this value is 80 cm.

- The height of the location of the first and second tier. Remember that in the interval between the first and second tier should be placed an adult in a sitting position. At the same time, the lower tier should not be too close to the floor surface, because under it you can organize a niche for baby clothes or toys.

- If you fear for the safety of your child "on the second floor", you can make a side for a children's bed with your own hands.

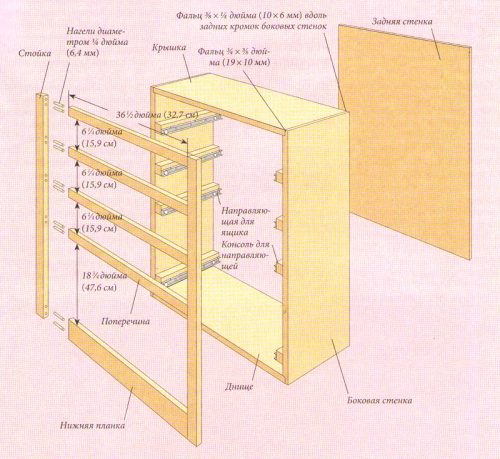

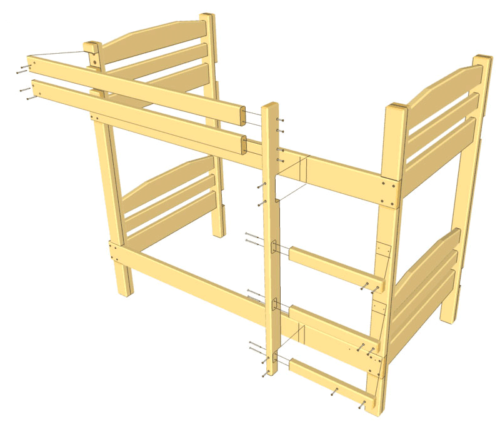

Examples of the drawings of a children's bunk bed do it yourself:

Children's bunk bed do it yourself

Materials and tools

To work on a bunk children's bed with your own hands, we need the following materials and tools:

- Boards 40x80, 30x30. It is best to choose a pine tree, as this variety of wood meets all the requirements. For the manufacture of one tier, approximately 9 boards will be required.

- Leaf of laminated chipboard. This material, in contrast to the wood, does not need pretreatment with protective compositions and grinding.

- 2 sheets of durable plywood 900x1900. For mounting the framework of the frame.

- Board 18x140 - for attaching a sun bed.

- Board for forming the base of sun beds. Typically, a bar 30x30 mm is taken for this.

- Boards and wooden planks for the manufacture of staircase (vertical and horizontal jumpers).

- Board for fixing the frame. Its dimensions - 40x140 mm.

- 3 Steel tubes.

- Fasteners - screws, washers.

- Glue - to handle the joints of the product.

- Screwdriver, drill.

- Protective compounds for handling wooden boards.

- Machine for grinding work.

- Sandpaper.

- Roulette, level - for design measurements.

- Saw, hacksaw - for cutting structural elements.

- Milling machine.

Selection of the mattress for a children's bunk bed

Dimensions of sleeping places depends on what mattresses will be used for a cot. Consider a little more, what they happen by the type of spring block:

- Mattresses made on the basis of a block with dependent springs. In order for such a product for a long time, it should have at least 130 special springs on his one square meter.

- Mattresses with a reinforced spring block. In this case, a flat springs are installed between the framework of the spring block. Between their ranks there are additional blocks made of polyurethane foam. This design gives sufficient rigidity and elasticity.

- Mattresses on blocks of independent springs (with orthopedic effect). In this case, each layer is usually in a separate shell. So, the child falls on this mattress and the body weight is evenly distributed over its surface, which makes it possible to relax well. In addition, the spine maintains the right position in terms of physiology.

In addition to spring blocks there are mattresses with other fillers. For cribs fit the following:

- Thermal felt. This material is combined from natural and synthetic threads. It is obtained by sintering performed by special technology, therefore it is characterized by high density. Felt is often used to protect the layers of the mattress from exposure to the spring block. This material makes the mattress durable and gives it additional rigidity.

- Coconut chips can be used as hard flooring. This material is usually obtained from coconut threads. They are treated with natural latex, which is why the coconut tile becomes elastic. It is noteworthy that the service life of such a flooring is much higher than that of various artificial fillers. This material is not amenable to rotting, deformation. At the same time, it does not absorb moisture, well ventilated, has antibacterial and anti-allergenic properties. This is hygienic, reliable and elastic material. Its use as a flooring makes mattress durable and elastic.

Children's bed do it yourself: the order of work

Order order:

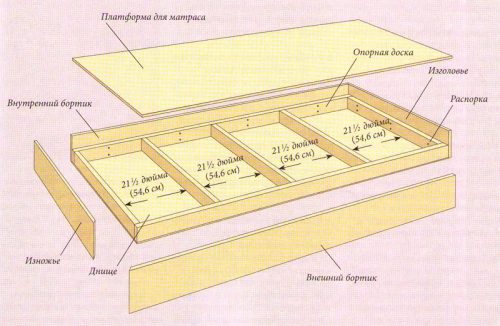

- First of all, you should decide with the type and size of the mattress used. It should be added to the magnitude of each side by 2-3 cm, thus you can calculate the sizes of the frame frame for the sun bed. With the help of the machine, cut on a sheet of plywood underlying the desired size.

- Based on previously made calculations, cut the frame and sides for a bunk bed from wooden bars.

- Carved sides with the help of self-samples attach to the previously made frame. For their manufacture we take a 150x20 mm board. As a result, two beds should turn out, 2 frames and 2 sides for each tier.

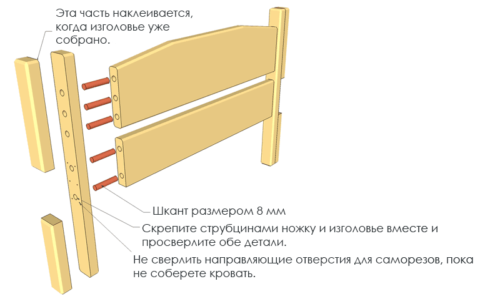

- Go to the manufacture of the bed legs. Since the design of the bunk bed is quite massive, it is better to use for this durable wooden bars 50x100 mm. In any case, the safety of the entire design depends on the reliability of the support. In order for the legs able to withstand the weight of the whole design, they are better made in the form of the letter "L". We connect the boards with the help of self-tapping screws, and the holes from the caps are smeared with a spacion mixture and squeeze sandpaper. Note that the length of the legs (support elements of the design) should be equal to the height of the sidelights located on the second tier.

- In the bars from which the legs of the design were manufactured, we put holes in the place where the second tier will be mounted. Next here comes in a big screw. We produce similar operations on each of the 4-legs.

- Wooden design should be additionally attached to the wall. To do this, the holes of the desired diameter are drilled in the mounting places. If the walls are made of drywall, then places for fastening wooden racks need to be placed strictly where metal profiles pass. For fastening, screws with hexagon heads and brackets are used.

- Go to the manufacture of fences for sun beds. It is they who will protect children from falling from a height during sleep. In order to make a fence, the wooden boards are required 20x100 mm, which are attached further to the vertical wooden racks (50x100 mm). Wooden elements are fixed with the help of self-tapping screws. The enclosing structures themselves are made in such a way that they are opening to mount the stairs.

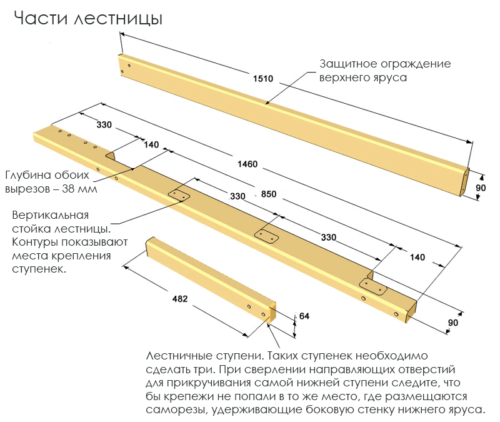

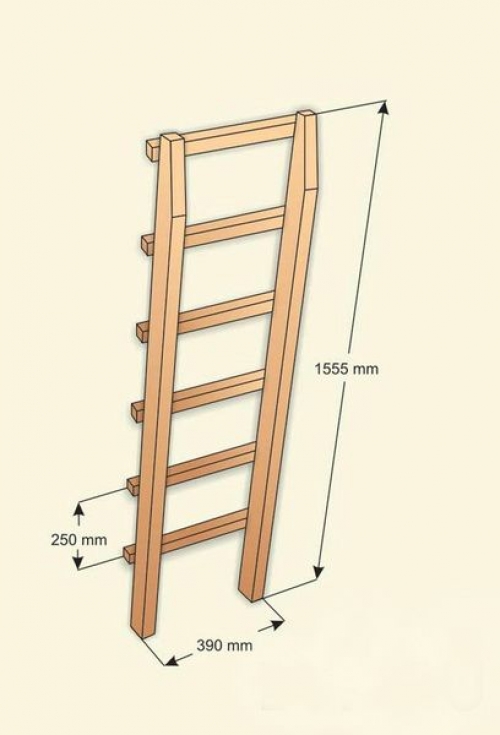

- Go to the manufacture of the stairs. They are usually made strictly vertical or under a slight inclination. For this, two supporting bars are prepared, on the side parts of which wooden steps are then attached. Bolts are used as fasteners.

- Sun beds from plywood are attached to the support frame. Next, the previously made fences are joined.

- Next, the reliability and safety of the design made is checked, because the bed is manufactured for children. If necessary, wooden structural elements are additionally secured by bolts and screws. The reliability of fixing the bed racks to the wall is checked using brackets.

- All wooden structural elements are processed by protective compositions, then covered with matte nitrolecom. Varnish should be applied in two layers.

Baby beds do it yourself: photo

The options for decor and design of children's bunk beds can be viewed in the photo: