There is always a table in any kitchen. Moreover, despite the variety of materials, people prefer to have wood products in their kitchen. Such furniture items can create an atmosphere of comfort and consent in your home. Today you can buy a wooden table for the kitchen in almost any furniture store. Moreover, the assortment is quite large and diverse. If desired, you can make it to order according to an individual sketch.

Content

In both cases, this piece of furniture will be quite expensive. Therefore, many prefer to make a wooden table independently. This will save a lot. Only to perform such carpentry work will require a special tool and carpenter skills. The complexity of the design and selected material also plays a role. So, consider how to make a wooden table with your own hands.

How to choose a table size

- In order to decide on the size of the kitchen, first of all, it is necessary to take into account the area of \u200b\u200bthe room and the place where it is planned to install finished furniture. For a family of four, a table of 90 by 90 or 100 per 100 centimeters will be enough.

- If the room is spacious enough, then you can put a large dining table in size 160 by 90 and 180 by 90 centimeters. At the same time, there should be enough space along it in order to freely move two people. On a holiday, up to 10-15 guests can fit at such a table.

- If the dimensions of the kitchen do not allow the table to move the table, then it is better to install a rectangular structure with a size of 120 by 75 or 120 by 80 centimeters. In this case, two people will sit behind the long side of the table and one on the short sides.

- Problems arise when you need to place guests at a table in a small kitchen. For this case, the so-called transformer table is suitable. In an unfolded state, it reaches a length of 230-280 centimeters, and in its folded size it is only 120 by 180 centimeters. Such tables are equipped with additional inserts for countertops with a width of 30-50 centimeters, which, if necessary, are located in the middle. If they are not needed, they are hidden in a special niche when the product is in a collected state.

- As for the height, it usually is only 70 centimeters. Although, depending on the needs, the dimensions can be less or more.

- When selecting sizes for the product, it is best to focus on how much useful area you can take him. After all, when everyone sits down at the table, there should still be enough free space for moving around. In this case, the presence of inconvenience for sitting guests is excluded.

The choice of material

It is very important to choose the right material for the manufacture of the kitchen table. It depends on how much the product will last you and what its resistance to various mechanical deformations will be. In addition, the cost of the structure of the structure depends on the type of material.

The most durable and environmentally friendly products from a wooden array are considered. They are very expensive. In order to independently make a design of wood massif, the skills of a carpenter and a carpenter will be needed. In addition, you will need a special tool and workshop.

For the kitchen table, the density of wood is very important. If it is soft, then scratches and traces will easily appear on its surface. In general, it is customary to distinguish between three categories of wood:

- Soft.

- Hard.

- Increased density.

Adviсe:

- For the manufacture of a dining table, you can use any wood. For example, walnut. This design will be strong and heavy. Next, it will need to be covered with several layers of varnish.

- Perhaps the best option for the manufacture of the dining table will be oak. This is a very durable, strong and solid tree. It is easily processed and covered with varnish. During operation, it does not deform, does not warp, does not split, is not subject to decay, which is very important for the table that is in the kitchen.

- Such trees like larch and linden requires coating with protective equipment. Otherwise, the design of these materials may quickly become unusable.

- In addition to solid wood, kitchen tables are made from chipboard with a thickness of 18-22 millimeters. MDF and plywood are used for the same purpose.

What are kitchen wooden tables

There are a lot of forms and configurations of such items of furniture. Most importantly, choose the one that would harmoniously fit into your interior.

A selection of supports for design

So, kitchen tables are distinguished by the quantity, shape and size of the legs. What they will depend on the following parameters:

- Form of the product.

- The size of the table.

- Type of material.

Recommendations for choosing supports:

- The legs can be made independently or purchased ready -made. If you decide to make them with your own hands, then you should know that this is a very laborious task. Therefore, many buy finished products. On sale today you can find metal and wooden legs with decorative carving.

- As for the quantity, the dining table can have either one or several supports. It all depends on the shape and severity of the countertop.

- If the table is placed on one leg, then it is usually made massive. Additionally, it is decorated with thread. Products with such a leg most often have a round shape.

- The table can also be installed on two massive legs. Between them there is a boat board. Such structures usually have a rectangular or oval shape.

- Most often, dining wooden tables are installed on four legs. Such products usually have a round, square, oval or rectangular shape.

- As for the shape of the legs, it can be very diverse.

Choosing a countertop option

Another important part of the table is the countertop. It can be made of an array of wood, chipboard or even glass. Obviously, massive constructions with a countertop made of whole wood are the most reliable and attractive. Tables from chipboard do not stand out with anything remarkable.

The optimal thickness for the countertop is considered 25 millimeters. If a smaller chipboard is used, then below should be installed a false dine of plywood sheet. It will serve as an increase.

The shape of the countertop is not as diverse as the designs of the legs. Basically, round, oval, square and rectangular tables are distinguished.

Round table:

Round is not suitable for every room. Their advantages include the following:

- It will look good in the dining room or large kitchen.

- This design allows you to experiment with support. You can use both one leg, and three, and four. Two cannot be used, since this table will be unstable. The most reliable designs on four legs are considered.

Of the shortcomings, it should be noted:

- A round table requires more space. In a small kitchen, it will be very crowded with him.

- This type of countertop is difficult to do independently.

Oval tables can be of various sizes. You can choose a small for compact kitchen, but the most popular are medium and large products. If there is little space in the house, then you can purchase an oval sliding table. His countertop is divided in half. In this case, in a folded state, the product can have a round shape.

Oval table:

But not only oval tables are sliding. Such an opportunity can also be in structures of round and rectangular shape. The easiest to manufacture is a rectangular table. After all, it does not require rounding of angles with tools.

Sliding table:

In general, sliding mechanisms can be different. One of them is a counterattack for metal guides. A special section is inserted between the two halves in an unfolded state, which is placed in the middle of the table and folded in a folded form under the countertop.

Tables with a glass countertop are quite popular. Glass in this case is usually fruit. This surface is very difficult to scratch. Designs on wooden legs with a glass countertop are suitable for rooms in the style of modern, minimalism or high-tech. The legs of such a table are attached using special fasteners.

Glass countertop:

There is another transformer table. In a folded state, it is a small compact bedside table. Up to 15 people can fit behind it. Such structures usually have a rectangular shape.

Transformer table:

Wooden tables: photo (rectangular shape):

How to make a wooden table with your own hands

Design

The design of the wooden table is represented by the following details:

- Selecting countertops.

- Longitudinal bar.

- Legs-stands.

- The transverse ribs of stiffness.

- Supports.

First of all, it is worth sketching on paper a sketch of the future product indicating the exact size.

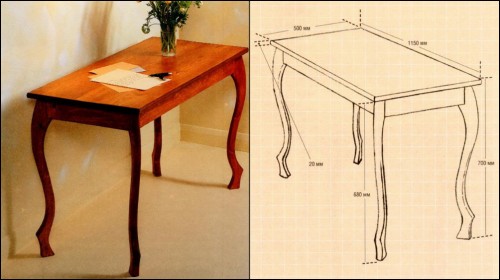

The drawing of a wooden table looks like this:

Focusing on the existing scheme, you need to cut the wood into the necessary structural elements.

Tools

For further work, the following tools will be needed:

- Hacksaw.

- Electrician.

- Small power drill.

- Plane.

- Milling machine.

- Big painting brush.

From the materials you will need:

- Bolts 8 mm.

- An sandpaper.

- Varnish.

- Furniture shield.

- Boards with a thickness of 21-22 millimeters.

The order of work

- First of all, it is necessary to give shape to the cut details. It is best to start with the legs. They will be straight with cuts. Their design can be made using a jigsaw. After that, you need to polish and give them a rounded shape.

- The design of the legs-shores consists of two horizontal and two vertical racks. Between themselves, they should be connected using ordinary bolts, which are necessarily fixed by a nut.

- When both vertical legs-strokes are fastened with horizontal ones, it is necessary to insert a longitudinal connection between the racks into a special groove. This will record both vertical supports.

After the legs are ready, the countertop should be installed. To do this, you need to perform the following order of actions:

- Put a furniture shield.

- Install horizontal stiffeners in places where it is planned to fix vertical racks. Their width should coincide with the size of the countertop.

- Through the strips of stiffness ribs, secure selecting from wooden bars on top with self -tapping screws. First, the strips on the long side of the countertop should be fixed. Then perpendicular bars are attached to them. Fastening is carried out using self -tapping screws.

- It is better to close the free space between the countertop and fixed bars with a decorative bar made of wood. This is done as follows:

- make openings for dadies in the bars and planks;

- insert cakes greased with glue into them;

- on sticking dumplings should be put on a decorative bar.

In order to finish the assembly of the table, you need to fasten the legs of the structure to the countertop using bolts.