Wall regiments replace bulky furniture. Today, more and more people prefer compact and ergonomic constructions that allow you to accommodate the maximum of objects. A do -it -yourself wooden shelf will give your interior a note of individuality and creativity, since a home -made regiment can become the embodiment of your most unusual wishes.

Content

Description of wood shelves

Before you start making a wood shelf, you need to figure out what this item is of the interior, and what types of shelves exist.

The most standard shelves in any apartment or house are an almost integral accessory playing the role of both decorative decoration and the most popular furniture element. In the office on the shelves there are folders and documents, dishes and other kitchen accessories in the kitchen, and in the hallway, they serve as a repository of all kinds of improvised objects: lipsticks, gloves and keys. Outwardly, it is a furniture product that does not have the front wall, which is made from different types of raw materials and is intended for storing various items.

Classic material for making shelves is a tree. It is easy to work and process with a tree, and its service life is quite large, provided that the wooden regiment will be in optimal conditions with minimal humidity. At the same time, the advantages of this material are obvious. First of all, this is: high quality of the finished product, strength, durability and, importantly, environmental friendliness.

As a rule, hinged shelves are most often wooden, due to the fact that they are quite strong and hardy. The additionally processed wood with a protective coating can serve you for many years.

You can view photos of wooden shelves made in compliance with various stylistic solutions below.

Types of shelves

Shelves are:

- Wall.

Such shelves, as a rule, are placed above the desktop, sofa and bed. They are usually fixed with brackets, which, in turn, are planted on special pins.

Wall are divided into:

- classic. The most common shelves due to the simplicity of their design and ease of installation. Are both square and asymmetric;

- floor. They look in the form of shoes, relevant in large rooms, corridors and hallways. It can be a shelf for shoes of different sizes made of wooden parts;

- open and closed type, shelves, as a rule, are wooden, can be carved and often serve as a decorative decoration of the interior. They are made with sliding glass and without it.

- Suspended.

They are attached directly to the wall with cables, belts, chains and other fasteners.

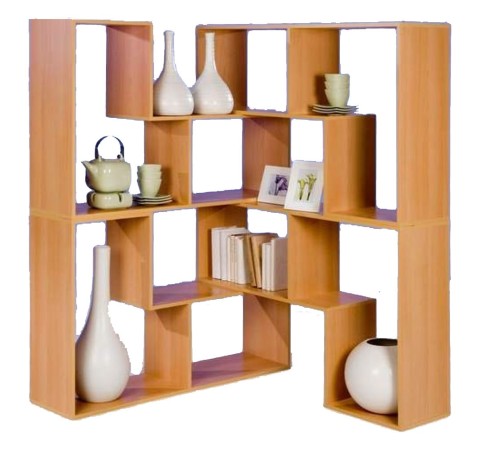

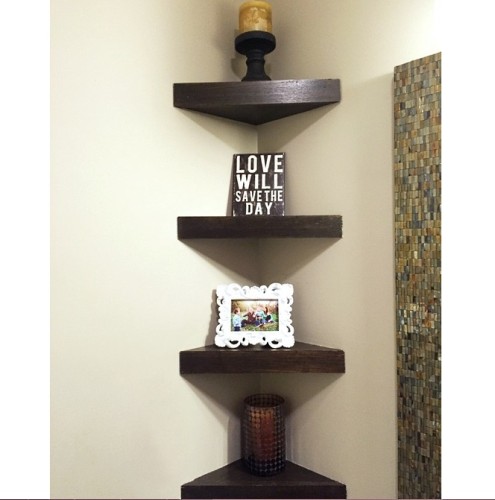

- Corner.

Are located between the adjacent walls in the corner. The mounting of the corner shelves can be performed both to the wall and to the ceiling.

Materials for the manufacture of shelves:

- Tree.

- Metal.

- Glass.

- Wood-and-fiber stoves and wood-fiber slabs of small-dispersed fraction.

- Gypsum fiber sheets.

- Combined shelves of two or more materials.

In their constructive features, shelves are:

- console type;

- with walls on the sides and without them;

- with the back wall and without it;

- vertical performance and horizontal;

- with doors;

- multi -tiered;

- having rounded corners and straight;

- inclined and straight.

In conditions of a certain design, you can make a suitable shelf, with or without backlighting, combining the color of the walls in the room and the general texture.

Load on wooden shelves

Before making shelves, it is important to decide on the most acceptable load on them, which depends on such nuances:

- the thickness of the tree. The more items you plan to arrange on the shelf, the thicker the board should be. In addition, the smaller there are knots on the board, the more hard it will be;

- the method of fastening. The finished wooden structure can be fixed on the wall using metal brackets, bars or special ears. The most reliable and durable mount are brackets;

- the number of mounts on the shelf. We are talking about long shelves for conservation designed to withstand the large weight. For example, a 3 m shelf should have at least 5 fasteners at a half -meter distance from each other.

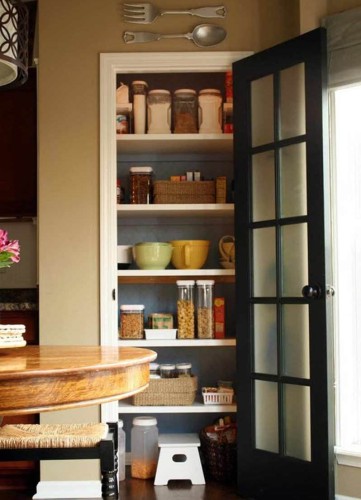

Do -it -yourself shelf

The manufacture of shelves from wooden parts should be started with the selection of tools necessary for work. In order to equip the room of the pantry, you will need:

- wood thick 2.5-3.0 cm;

- a beam with a cross -section of 2x3 m;

- 1 metal bracket (with a pantry with a width of more than 80 cm);

- pencil for marking;

- construction level;

- self -tapping screws;

- drill.

Stages of manufacturing wooden shelves in the pantry:

- With a pencil, make markings on the wall and decide on how many shelves must be placed on the back of the pantry. The preferred option for placing floors is 30 cm in steps.

- Using the level, make horizontal lines.

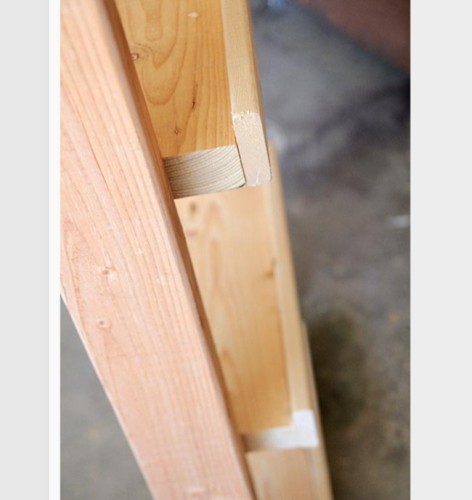

- Having made a marking, attach wooden bars cut in terms of sizes. The length of one on the sides should be 30 cm (this is the standard depth of the shelf, which allows you to install a 3-liter jar or box on it).

- When fastening the bar, use self -tapping screws under the hexagon. Three self -tapping screws will be required for long bars, and two for short ones.

- Work only with a processed tree. To do this, replace the trimmed boards with sandpaper or a grinder with a special nozzle.

- Attach the boards to the walls on the wall with self -tapping screws. The length of the screws is determined at 3.5-4 cm.

- If you do not have a special pipe for furniture, then buy it. It is necessary so that the shelves do not bend under the weight of the load.

- Cut the pipe in size corresponding to the height between the floor and the first shelf, strengthen the first shelf.

- Insert the pipe and fix it with flanges.

- By the same principle, strengthen all the other shelves among themselves.

- Thanks to simple and simple actions, we got a compact and convenient wooden rack, in which each shelf is able to withstand fairly large loads.

DIY wall shelf

Before making a wooden shelf, read the instructions for its manufacture, as well as collect a set of necessary tools.

For work, you will need:

- electric drill;

- knife, pencil, ruler;

- wood with a thickness of 1.5 cm;

- a sheet of plywood for the walls of a shelf 6 mm thick;

- sliding glass;

- reiki for glasses;

- grinding grinder;

- brackets;

- carnations and screws;

- dowel.

Stages of manufacturing a wall shelf with your own hands:

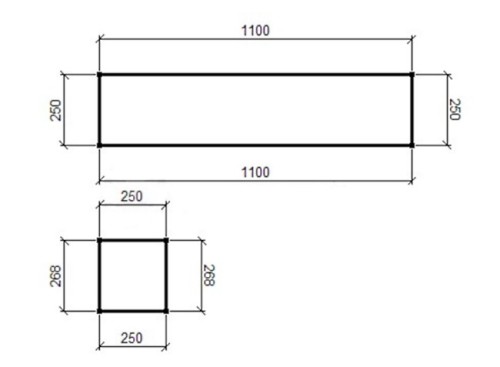

- Such a shelf of wooden materials of a wall type is best made according to a pre -planned drawing. In our case, this is a rectangular design. Its sizes are visible in the figure below.

- Sprinkle wood with a jigsaw according to the available sizes.

- In order to level ugly cuts, pushing them with a melamine edge. To do this, walk along the edge in the place with a hot iron and then, when it sticks, cut the extra pieces with scissors.

- On the horizontal parts of the shelf, retreating along the edges of 5 cm, make holes. In this case, the diameter of the drill should not exceed the diameters of fasteners.

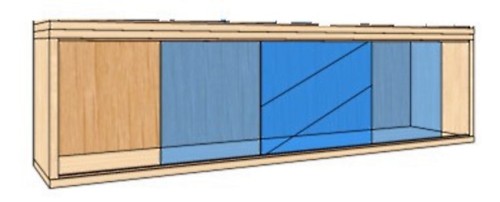

- Gather the shelf. To do this, cut the wall for the future shelf from the plywood sheet and fasten it to horizontal boards. Attach guide rails for glasses. Fight all the details of the shelves as shown in the figure below.

- Attach the brackets to the side walls from the end. Then make marks on the wall, drill holes, insert the dowel, and in them, self -tapping screws, so that the latter perform a little from the wall so that you can hang a shelf.

- Insert into the glass shelf and hang in a new place. The wall regiment is ready. Such wooden shelves can be successfully used as a stand for colors.

Corner wooden shelves are made according to a similar principle:

- details of the angular shape, about 5 cm thick, according to the drawing;

- then they are painted in the required color;

- with the help of self -tapping screws and drills, the shelves are attached in the corner over the other. That's all. The manufacture of such shelves will not take much time, and to everything else, such furniture looks very pretty.

How to choose and prepare wood:

- In the market, you should choose exclusively dry raw materials. And if there is suitable wood on your attic or on the balcony, but already damp, then dry it well. Lay the tree on top of each other and crush something very heavy. This is done so that the tree does not crumble, being ready -made furniture.

- Before the manufacture of furniture, be sure to prepare the tree in the proper way: polish with sandpaper, then cover with a stain and paint.

- The color of the edge of the wood and the shade of the wooden shelf itself should coincide. In harmony with furniture, brackets should be selected.

Do -it -yourself decorative shelf

Such an original flower shelf can be placed on the wall, and this will significantly save the territory of the room. And for the manufacture of the model, it is recommended to use a tree as the most affordable and suppressive material.

For work, you will need:

- wide woods made of wood, 2 pcs. 700 mm long; and 3 pcs. 280 mm long;

- narrow boards, 3 pcs. 280 mm long;

- paint for wood, varnish;

- sandpaper;

- drill;

- a hammer with nails;

- decorative twine.

Stages of manufacturing a decorative shelf for flowers:

- After that, with the help of nails, fasten with each other long and short boards as shown in the figure.

- Before starting work, prepare a tree by fingering it with sandpaper.

- Attach narrow short boards to horizontal wide. This will be a limiter so that the flowers do not slip off the shelves.

- At the top on long boards, make through the through holes for attaching to the wall.

- Then treat the tree with a stain and varnish. Summarize uneven corners and at the end cover the structure with a layer of varnish.

- Pass the twine into the prepared holes and fix the knots. The shelf is ready, it can be hung on the wall and decorated with flowers.