The gate is an indispensable component of any garage, because it is they who protect the internal space from the penetration of outsiders. In addition, the garage gates should act as a strong and reliable fourth wall, not be afraid of temperature changes, humidity, and look attractive outwardly. The easiest way to buy them or order manufacturing, but this will not save and will not be as pleasant as if you built garage gates with your own hands. After reading this article, you will learn how to make strong gates with simple tools.

Content

Garage swing gates

If the purchase of ready -made gates does not seduce you, then there is only one way out - make them yourself. And the reason for this may be not so much the financial side as the need to create something useful and durable than it will be pleasant to use every day. And while the walls, the foundation and roof protect your car from bad weather, the gate perform a much more important function - they protect the car from possible theft and damage. If the gates are strong and reliable, in the garage you can not be afraid to leave an expensive tool and other items that have no place in the house.

There are several types of gates on the principle of opening, and in this article we will consider the step -by -step creation of swing and lifting structures. Thus, you can evaluate and compare the features of both systems and choose the optimal one.

The swing garage gates, as you can guess from the name, open, opening access to the room. They consist of one or two wings, frames, loops and other elements. The size of the wings and the number of accessories on them can be very different, so the work should begin with the creation of a detailed drawing. If you set the gate in an existing doorway, then you need to build on its size, however, if you plan to reduce or increase the opening, take into account the following recommendations:

- From the lateral part of the car to the gate rack, it should be at least 30 cm. It is better to increase the distance in case you use the same garage for a larger car in the future.

- The opening should be at least 2 m, but it is better to make it 2.1-2.4 m.

- Choose steel sheets with a thickness of at least 3 mm.

Assembly of swing garage gates

For standard swing gates, sheet metal, metal corners, profile, loops, valves and locks will be needed. To work with metal, prepare a welding machine and a grinder, a square, roulette and a building level will also come in handy.

We make garage gates:

- First of all, you need to assemble the frame. To do this, you will need a welding machine and elementary skills of handling it. Cut the profile with a grinder into separate elements in accordance with the parameters in the drawing, put them on a flat plane, weld the seams and clean them to get a perfectly smooth surface. The seams are the most vulnerable place from which corrosion and destruction begins, so do not neglect treatment. In addition, if they are not smooth, future wings will not be able to close tightly. Make an external and inner frame in this way.

- Next, from a metal profile 60x20, weld the frame for each sash. Check the evenness of the angles using a square. Between the sections and the frame, leave a small clearance, so that it is convenient to open the doors.

- Attach the sheet metal to the frame so that the canvas of the left sash enters the frame with the right one a couple of centimeters, and the right one should already be on the same distance.

- It is better to prepare the loops in advance. Weld the lower part of the loop to the frame, the upper to the canvas. To make the mount stronger, use the reinforcement, welding it from the inside.

- To increase safety, in addition to a conventional lock, it is better to use a bolt by installing it on the inside of the gate. But to make a bolt rationally only if the design provides for the gate. So you will first enter the garage through the gate, open the bolt from the inside and open the gate completely. Castles can be chosen of metal or hinged. In the first case, the installation will require additional metal plastic, and in the second - external loops. It is better not to limit yourself to one lock, but to put at once 2-3, so that in the event of a breakdown of one of them you can still close the garage.

- It remains only to paint the gate, and you need to do this until the moment of installation. Painting is necessary not so much for aesthetics as to protect metal components from corrosion. Accordingly, for this, you need to use atmospheric anti -corrosion paint for metal. It can be applied manually with a brush or roller or with aerosols, which is much faster and more convenient. Before applying the paint, the surface should be primed. It is better to apply paint in 2-3 layers and renew the coating every couple of years.

Installation of swing garage gates

When the paint dries, you can install swing sectional garage gates. To fix the internal and outer parts of the frame, use metal pins about 15 cm long. Fix them in the slopes, cut and polish the ends so that they do not complicate the closure of the wishes. Between themselves, fasten the two parts of the frame with steel plates with a thickness of 4 mm, welding every 50 cm, after which the finished sash can be hung on the hinges.

At this stage, it is worth thinking about the insulation of the garage gate, since only almost 50% of heat goes through them. If you prepare elementary materials, it is very simple to do it. Swate a wooden crate from lumber, fix it from the inside of the wings, and then fill it with insulation. As thermal insulation, you can use the cheapest materials, for example, stone cotton wool or polystyrene. You can close the crate with a lining.

Lifting garage gates

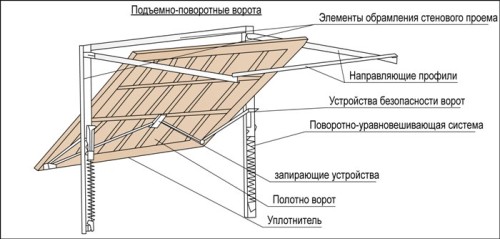

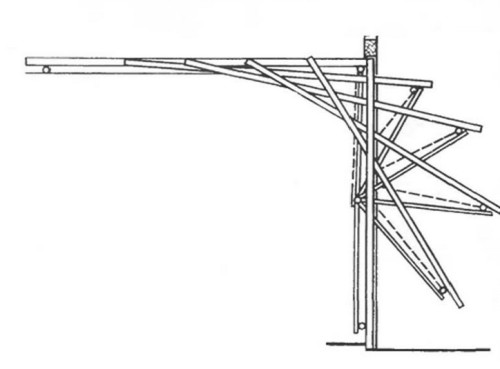

The lifting garage gates are very popular, but it seems to many that it is completely impossible to make them with their own hands without appropriate experience. In this part of the article, we will try to prove the opposite. First of all, we will consider what the design itself is and what is its advantages compared to the swinging. Opening, the canvas of such a gate on the hinges rises under the ceiling of the garage, moving from a vertical position to horizontal. Thus, it takes up much less space than swing sash.

There are two types of lifting gate structures:

- Lifting and secto-consist of several sections about 50 cm wide. For the construction of panels, wood, metal or plastic can be used. The inner emptiness between the frames of the frame is filled with polyurethane heaters. The sections are connected by articulated loops with plastic or steel mobile details (quality, durability and cost depend on the material). Such gates are very convenient and easy to manage, but they have a rather low protection against hacking. In addition, it is very difficult to make them yourself, especially if there are no design skills. Nevertheless, there is an opportunity to save by buying a ready -made set and putting it on your own.

- Lifle-and-liver-have only one sash, which rises by means of hinges and levers. Unlike the previous type, such a gate is well protected by the garage from the penetration of ill -wishers.

In the case of such a gate, the noiselessness of their work plays an important role, since their design does not involve the use of rollers with guides, but the decisive factor is that it can be made by yourself. For this, you do not need special skills and large financial investments.

Lifting garage gate device

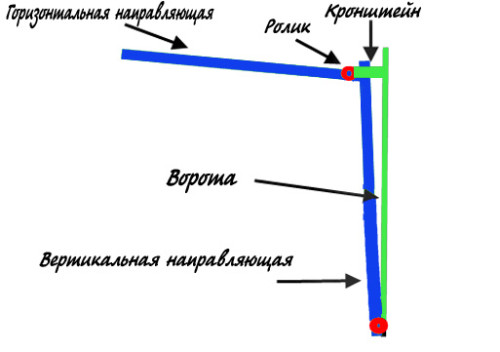

The lifting and dwelling structure consists of a frame, a sash and an increase in the mechanism. For the frame, you can use not only steel, but also wooden beams that are installed in the opening. In the doorbell, guide profiles are placed on which the gate will move when lifting and lowering.

The obvious dignity of the lifting and housing gate is the integrity of the canvas. It can be made of wood, it can be sheathed with sandwich panels or metal. The whole wooden canvas will cost quite expensive, while it will weigh a lot, and the material itself is not as stable and durable as plastic or metal, although it looks beautiful. The optimal and most common options are wooden or plastic panels and sheet steel. The sandwich panels in this regard is even better, since they play the role of casing and thermal insulation. Other materials will need to be additionally insulated with polystyrene or stone slabs.

Technology for the manufacture of lifting garage gates

Before installing the roller garage gates, it is necessary to decide on the opening mechanism.

There are two types of devices:

- Sharpish-red-haired-a popular solution that guarantees a simple course of the sash and anti-locks of the canvas. However, such a mechanism requires a very accurate installation of guides, as well as a scrupulous setting of springs tension, which is unlikely to make a newcomer. If you do not put the guides strictly vertically and parallel to each other, the shield will be blocked.

- On the counterweights - the principle of action is that the cable attached to the lower corners of the frame and missed through the block leads to the pulley of the winch, and at the other end it is fixed by counterweight. The heavier the gate canvas, the harder this counterweight should be. However, it should be taken into account that the design is subjected to large loads, so it is mainly used to build a massive gate, and for private garages for 1 car I use a hinge-red mechanism.

When you have decided on the project of the future gate, you suffered the dimensions of the opening and developed a sketch, it is time to prepare tools and materials.

Consider the construction of the lifting gate on the example of a design for which the following will need:

- steel pins (scraps of reinforcement 15-18 cm long);

- wooden beam 120x80 (racks) and 100x100 (crossbag);

- steel corners 40x40x4 and 3.5x3.5x0.4;

- channel bracket 8x4.3x0.5;

- spring D30 mm;

- plywood shields;

- sheet steel;

- steel rod D8 mm.

How to install garage gates:

- Take 2 racks, cross -teal and solve the box, connecting the parts with corners or plates. The lower part is pulled into a concrete screed by 2 cm.

- Fix the box in the opening with steel pins.

- Collect the frame of the canvas and coordinate the plywood, attach sheet iron on the outside.

- From the corner, create a support for the mechanism.

- In one of the shelves, make a hole for fixing to the racks, in the other make holes for the spring bracket. To fix the bracket, which will be used as a support under the spring, drill 3 holes.

- Make an adjusting plate from the steel strip and use it to connect the spring with the bracket. Ground the springs extremely plots with pliers to make hooks and attach the steel rod from below.

- From the corner, make a hinged angle and weld to the frame. Thus, you can mount a lifting lever on a hinged 12 cm.

- Attach the plate for the tension regulator to the end of the lever.

- From a pair of corners, build guide rails for the course of the gate themselves. To do this, weld the corners along the edge, making sure that the internal distance between the peaks is strictly 5 cm along the entire length.

- Attach the rail to the plate, leaving the clearance of 8 cm between the lower end of the cross -member and the axis.

- At the other end, 12-15 cm from the bottom, attach the channel, then attach it to the ceiling beam (use a bolt connection).

- At each stage, before fixing anything, check the horizontal guides.

Useful advice: to make it lighter in the garage, dull windows can be made in the canvas. To give the design of additional strength and in order to avoid random blows and damage, glue a rubber kant with compensating overlays to the canvas.

Finally, we suggest that you familiarize yourself with the video where the garage gates of the lifting type are shown in all details:

Garage Gate: Photo

Recently, the artistic painting of the garage gate has been gaining great popularity. Pictures with 3D effect are in special demand: