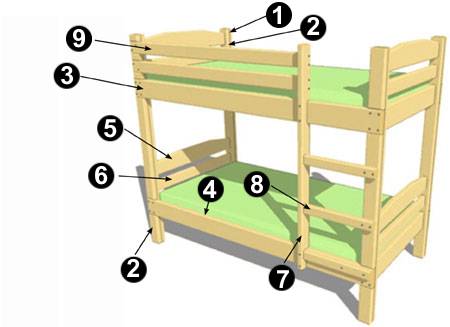

Bueling beds are an excellent solution if it is required to save space in the children's room. Thanks to this, a lot of useful area is released in the room. But the requirements for such beds are higher than the usual. So, such designs should at least have sufficient strength and stability. This must be taken into account when designing such a bed. In addition to sleeping places, it is necessary to ensure a convenient and safe rise to the second tier. Usually for this purpose they build a staircase. When developing a project of such a bed, it is important to think over the location of this staircase.

Content

In addition, it is necessary to make the correct calculation of the length of the sleeping places, as well as the distance between the tiers. The bed should turn out such that there is enough free space from the floor to the lower sunbed. It should be enough for an adult can easily sit on a sunbed. At the same time, the resulting niche can be occupied with something. For example, a box with bedding or toys. As for the upper tier, you should not place it too high, even if the ceilings allow it. The fact is that in the upper part of the room the air is usually warmer, and, therefore, it will be stuffy here. In addition, it is dangerous for the child himself. Read more about how to make a bunk bed for children - further.

Selection of materials

As a material for the manufacture of a wooden bunk bed, pine is most often used. So, it will require boards of the desired size, most often it is 30 × 30, 40 × 80, as well as 20 × 150. The length of the bars for each part of the future bunk bed for children is usually calculated pre -calculated. At the same time, it should be taken into account from which type of board you need to make the detail of the bed. So, from pine bars to make a bed is somewhat more difficult than from another breed of wood. Therefore, if you have no experience of such work, then it is better to abandon the pine tree and take as the main material a bars of oak or ash. So you will facilitate your job and increase the chance of a successful quality result. If there is a place and there is a desire, then you can even make a bunk bed with a sofa.

For the manufacture of a bed, in addition to wood, sheets of plywood are needed for each tier, which will play the role of the base for mattresses. The dimensions of such sheets most often make up 900x1850x10 mm. In addition, to fasten the details with each other, you will need screws and pucks of the bunks. The assembly is best done in the room with humidity and temperature close to those that will be present in the children's room. If this is not taken into account, then the boards can be deformed over time.

How to choose the size of the bed

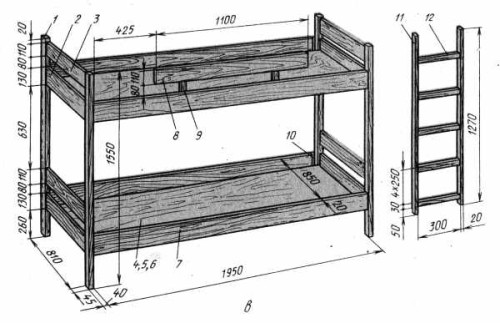

For the manufacture of any children's two -tier bed, it is necessary to prepare drawings in advance. And it is better not to use ready -made options, but to make them yourself or order. The fact is that ready -made drawings may not be suitable for several reasons. So, when selecting the size of the structure, first of all, it is necessary to correctly determine its height, and only after that the width and length. Most often, the dimensions of the bed are selected with a margin so that the children can sleep on it for several years and do not have time to grow out of it. Most often, such a bed is made 190 cm long, and 90 cm wide. In addition, you need to take into account the dimensions of the mattress that is planned to be used. In this case, the length of the bed should be larger than the mattress in width by about 9 cm, and in length by 11 cm.

As for the height of the bed, when it is selected, first of all, the dimensions of the room are taken into account. Moreover, there should be enough space on top for convenient movement of the child. It is better to make the height such that the child sitting on the second tier does not reach the ceiling with his hands. A similar principle is used to select the distance between the tiers. So, an adult sitting on the lower sunbed should not reach the upper tier with his head. As for the bottom of the lower sunbed, it should be from the floor at a distance of at least 310 mm. When calculating the ratio, it is also recommended to take into account the thickness of the mattresses used.

If you still want to use the finished drawing, it is recommended to check if the sizes indicated on it are suitable for your room. If necessary, you can take as a basis a finished project and create your own on its base. At the same time, it is recommended to take care of strengthening the structure of the structure so that it is stable and reliable. If the room has a small area, then perhaps you should give preference to the construction of a compact children's two -tier bed with a cabinet.

How to make a bunk bed

The main points

In order to minimize the costs of making the product, it is recommended to calculate all the necessary materials before they are engaged in their purchase. It will be necessary to make two sunbeds in the form of grilles on which mattresses will be laid. For their manufacture, you will need boards in size 18 × 140 mm. For each sunbed will need 10 boards. A similar design should be strong enough. The width of the berth should be at least 85 cm. So that the sunbeam rises into place without problems, it should be done a little already. As a support for a grille for a mattress, you can use a bar of 30 × 30 mm in size.

The upper tier of such a bed should have special sides so that the child does not fall from a height. In addition, it is necessary to install the staircase on the second tier. The staircase and sides are made from a board in size of 40 × 80 mm. If desired, you can make the same side for the lower tier. The right number of boards is calculated depending on the type of side and location of the stairs. The bed itself for its strengthening must be pulled out by a massive board around the perimeter. For this purpose, a board is suitable for 40 × 140 mm. It should be noted that a two -tier children's bed from chipboard is assembled more heavier than from whole wood. At the same time, it costs much cheaper.

Phased assembly

For the manufacture of the product, you will need:

- hacksaw,

- screwdriver,

- milling machine,

- roulette,

- level.

Let us consider in more detail the process of assembling a children's two -story bed:

- First of all, the frame of the shelves of the bed is collected. To do this, a nest is cut out in the beam, the depth of which is approximately half the thickness of the tree. These bars are useful in order to connect transverse and longitudinal boards.

- When the frame is assembled, it is necessary to check its perpendicularity. Next, plywood shields are attached to the frame, previously greased with carpentry glue.

- The compounds need to be strengthened using screws, while between neighboring screws there should be a distance of about 20 cm. When the bed shelves are ready, they need to be thoroughly dried, and then polished.

- After that, you can start assembling the stairs. To do this, the racks are first marked, and then small holes with a diameter of 30 mm and a depth of 17 mm are drilled with a feather drill.

- When the hole is cut out, iron rods are inserted into it, which then need to be fixed using screws. The wall can also be smeared with carpentry for reliability.

- Now you can connect the bed racks with the shelves. To make the beds of the bed stronger, first it is necessary to mark the height of the attachment of each of the shelves. This, as a rule, is done from the inside of the racks.

- The shelves are tightened with clamps, their perpendicularity will necessarily be checked and tags are made for fasteners. Next on both sides of the boards, holes are drilled. Then it remains to fix the shelves and tighten the screws.

- When the bed racks are connected to the shelves, you can do a decorative edging. You need to find out what distance between the racks, and then saw off and fit the edging boards.

- In order for the bars to be not noticeable, they are installed approximately 45 mm below the frame. Next, the edging is attached to the shelves using screws.

- After that, you can start installing the stairs. For fastening the left rack to the bed, screws are used in the amount of 4 pieces. To the lower edging, the right stand should be screwed by one, and to the upper - three screws. At the same time, the fasteners need to be tightened from the inside of the bed.

- After installing the stairs, you can proceed to the installation of fences on the upper tier. They should not only be quite stable, but also have a beautiful appearance. After all, the bed should become an additional decoration of the room.

- Longitudinal and transverse boards with a size of 70 × 20 mm are usually crashed into racks, namely, into special nests in the racks, which should be made in advance using a chisel. The fence is usually not made on the lower sunbed. Reiki are fixed with screws from all sides.

- The existing openings between the fence and the edging must be closed with a cloth. It remains to paint and varnish the product in the collection. In order for the crib to be more stable, it must be additionally attached to the wall by means of brackets.

Metal bunk bed

A double -tier bed of metal is collected somewhat more difficult than wooden, but at the same time it is easier for the design itself. The main difficulty is the use of the welding machine in the work. In addition, a person who will carry out assembly will need some experience of handling such equipment.

Frames of a sunbed such a bed are collected using metal corners with a size of 45 × 50 mm. For cutting products in size, a grinder or a hacksaw for metal is most often used. At the ends of the corners, it is necessary to cut the gaps in order to carry out a more dense docking of parts. After welding all elements, it is necessary to check whether they are placed exactly. In addition, it is necessary to determine the value of the right angle.

It should be noted that in the design of such a bed, unlike wooden, there are no sides. Vertical racks are made of a thin -walled pipe of diameters of 30 mm. The frame of the sunbed is attached to the finished racks using welding. After that, all welding seams must be treated. The bed will turn out to be more beautiful if for the upper tier, head of the head and wear, use forged sides. Therefore, such products are made to order in special workshops. If there are welding skills, the head of the beds can be made with your own hand from the pipe of the desired diameter and rods.