Wooden mills for the garden have always been a great way to “revive” the site and make variety to its aesthetic component. Small neat buildings create a feeling of comfort and tranquility. It seems that now small workers will leave the mill and begin to wear bags with flour ... If you want to decorate your site with one of such decorative mills, it is not at all necessary to spend a lot of money on the purchase of the finished product. Today you will learn how to make an original and neat mill on the site on your own.

Content

Making a wooden mill

Many people wonder how to make your plot beautiful and unlike the neighboring ones. It was this desire for landscape aesthetics that was the reason for the development of a separate area of \u200b\u200bdesign. Decorative sculptures and buildings are able to transform any site by setting it a certain style or harmoniously combining with the surrounding landscape and residential buildings. All such products are presented on the market in a wide range, private masters who make purely individual orders are also in demand. But if we are talking about a wooden decorative mill, then even a beginner in carpentry can cope with its creation. All that is required of you is the ability to handle elementary tools such as a hacksaw and drill.

The design of any mill can be visually divided into 3 main segments: lower (platform), medium (“body” or frame) and upper (blades and roof). For simplicity, each of these segments can be collected separately, and then combined into a single system. Consider this process in all details.

The lower part of the mill

Before proceeding with the description of the instructions for the manufacture of a decorative mill for the garden with your own hands, we suggest discussing the materials from which it will be built. Since we are starting from considerations of savings, but at the same time we do not want to sacrifice quality and aesthetics, a wooden pine beam or wide board will be the best option for creating a strong base.

To make the platform reliable and is able to withstand the load from the structure and atmospheric phenomena, choose a beam with a thickness of at least 50x50 mm. Glue a square frame with a side of 60 cm from it. If you use the boards, then the thickness of each should be at least 20 mm, and the width is 150-200 mm. If after the construction of a house or barn, your lining remains in the farm, it can also be used to create a platform. This is a strong and durable facing board that does not need finish. For the main material, you can take old cut cuts from shovels, then you can build something resembling a miniature log house.

When assembling a platform, it is extremely important to monitor the horizontal and verticality of all the adjacency. To do this, you need to collect it on a flat surface and use the building level. If there is no level, use roulette, checking the distance in diagonals.

If you are going to put a mill on naked ground or lawn, then it is necessary to carry out a thorough waterproofing of the base. Otherwise, the wood will quickly get wet, swell and begin to collapse, and after a month of operation in the open air the mill will become unusable. To prevent such a development of events, it is recommended to install a platform on low legs-stands. They can be made of polyvinyl chloride plumbing pipe of arbitrary diameter. The water pipe is inexpensive and available in any specialized store. To make the legs stable, put such thickness in the pipe beam inside each piece of pipe that they fit tightly inside. It remains only to fix them with self -tapping screws and nail them to the lower part of the base on the inside of the corners.

During cutting the legs, make sure that they are all equal to length. Spend a repeated check after fixing the PVC tube to the platform. When the legs are fixed, sew the lower part of the platform with boards or lining, tightly adjusting the elements to each other. As a result, you should get something like a large stool.

Useful advice: to make ventilation and at the same time a stock for rainwater, drill 10-15 of a small diameter in the bottom of the future decorative mill. So moisture will be faster to evaporate from the inside, and the structure will last longer.

The frame of the mill

When the lowest segment is ready, you can start building a frame of a decorative mill for the garden with your own hands. The material for it should be selected from the same wood. Take 4 pine beams of 40x40 mm for the manufacture of the base and the same number of bars 25x25 mm for the top.

Gather the bars in the pyramid and solve galvanized nails. The construction of the middle part of the mill is the main step, since it sets the character of the structure. You can make a pyramidal frame or in the form of a rectangle, a polygon, you can twist the corners, etc. You can take as a basis the finished drawings of a decorative mill for the garden and add something of your own or modify the frame.

To give decorativeness in the middle segment, you can cut out small windows, balconies or doors. It is not necessary that they function, you only need to give them the appropriate appearance.

Find the resulting pyramid on the basis of bolts with nuts. So the design can be disassembled for the winter and put into the room before warm and dry weather. If you do not want to make it collapsible, you can connect the lower and middle parts with self -tapping screws or galvanized nails.

Roof and blades of the mill

The next step in the work will be the construction of a roof of a decorative mill. To do this, you need to collect 2 triangles 30x30x35 cm. Combine them with bars 60 cm on top, and attach to the lower part with wide boards.

In order for the construction to be as stable as possible, the triangular roof and the base of the pyramid must be planted on a vertical axis inserted into a pair of bearings. This will provide not only vertically fixation, but also allow the roof to rotate from the blow of the wind.

As an axis, use a metal hairpin 1.5 m long and a diameter of 14 mm. It must be fixed in the center of the middle boards of the base of the lid and the lower part of the frame pyramid. The carving on the axis should correspond to the length of the frame, which is approximately 1 m. In the upper and lower part, the axis should be fixed using a nut with a puck for free rotation on the central roof board.

In addition to the vertical axis, the horizontal axis should also be attached. To her end, the blades will subsequently be attached, which make the mill a mill. The length of the horizontal axis in this case is about 40 cm. It passes over the center of the vertical axis and is attached in the same way - a nut with a puck. Blue the boards to the base of the roof with an edge and cut in accordance with its geometry.

Useful advice: mount the bearings with solid bolts so that they pass through the entire width of the board.

In order for the wings of the mill to capture gusts of wind and rotate the roof, you need to make a special steering wheel. For its manufacture, put together two trapezoid parts of 4 boards, insert into the central axis. To make it better to work, it is recommended to sheathe it with leaf galvanized tin. Fix the axis on the basis of the roof on the other side of the propeller using a self -tapping screw.

Mill skin

Finally, you can begin to the final stage of work - lining the frame and blades. The same wooden lining is useful for this, but other lumber can be used. Speak the frame by placing the boards vertically. Make slots for doors and windows. If you do not want to mess with a jigsaw, you can simply nail pre -made decorative windows, doors and balconies to the continuous surface of the frame. Also, any cut figures are suitable for decor: hearts, rhombuses, animals, etc. Remember that here only your own fantasy can serve as a limiter, and there are no strict rules. For lining the roof on top, use galvanized steel or plastic, on the sides you can close it with lining.

In the manufacture of the wings of the mill, it is important to remember that they should not be too heavy. Otherwise, they will not be able to rotate or completely overturn the entire structure. Take a couple of pine boards of 150x5x2 (length, width, thickness), find their centers, add up crossrest. At the intersection, make the grooves so that the boards enter each other, after which pull the joint with bolts.

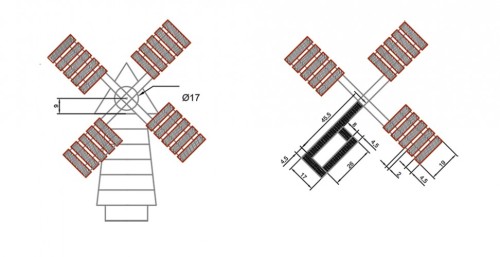

To each of the four blades equal to the length, fasten the wooden planks horizontally. The length of the planks should decline so that they form a trapezoid on the blades. In the photo of the decorative mill for the garden below shows just the following case:

It remains only to plant a cross on a horizontal axis. It is better to cut off the sticking part of the axis so that it does not violate the aesthetics of the structure.

Useful advice: so that the upper part is as stable as possible and easily rotate, put a metal plate with stiffeners on top of the middle segment on the vertical axis on top of the middle segment. In this case, the roof will not be able to lean aside or backward.

Processing and decorating the mill

The final stage of construction is the processing and painting of wood. Since you have collected a mill of wooden elements, it is necessary to properly protect them from destruction, otherwise all your efforts will be in vain. To do this, each of the segments must be treated with an antiseptic composition. It will protect the material from decay and damage to insect parasites. To not only disinfect wood, but also tint it, use a stain.

After drying the antiseptic, the surface can be varnished or paints. Here you can completely trust your imagination. But so that the mill does not look alapo, yet take into account the architectural features and landscape design of the site. For decoration, not only paints, but also other materials are suitable. For example, the base can be covered with pebbles or a decorative facing stone remaining after the construction of the house. It will also be interesting and funny to attract children to the mill. To make a painting, use gouache or acrylic paints.

After applying the paint, it is necessary to cover all the wooden surfaces (even non -painted) with atmospheric varnish. Since the mill will be in the open air, it is necessary that the varnish protects the wood from moisture and burnout under the sun. Alkidal varnish PF-170 and yacht varnish copes with this task. The latter costs more, but demonstrates high protective characteristics. Apply varnish in 2-3 layers, waiting for the complete drying of the previous one.

Useful advice: varnish a mill with a dry room closed, so that garbage does not stick during drying to the surface.

Also, for decoration, many set backlight. In this case, the mill not only decorates the personal plot, but also serves as a lighting device. Another idea of \u200b\u200ba beautiful design is to combine a building with a miniature reservoir, building a decorative water mill for the garden. About how to create a personal pond, you can learn from articles " With your own plastic pond for giving" And " How to make a pond from the old bath».

We hope this article helped you deal with technology and finally we offer to get acquainted with informative video about decorative mills for the garden with your own hands: