To poke steam rooms or bath, various heating devices are used. One of these devices is the cast -iron furnace for the bathroom “Hephaestus”. This manufacturer has established itself with high quality products and the effectiveness of its use. We will talk about the features, advantages and connection of the Hephaestan furnace.

Content

Characteristic and advantages of using the cast -iron furnaces "Hephaestus"

A bath is a rather popular type of relaxation that is in great demand and high popularity. The bathhouse helps not only to cleanse the body, but also helps to improve health and emotional state. A constant visit to the bath helps to improve blood circulation, pressure and immunity.

But, the quality of the bath directly depends on the furnace used to heat it. In ancient times, brick stoves were the most popular, now, with the development of technology, stoves made of steel or cast iron are increasingly used.

Wanting to save on the construction of a stove in a bathhouse, sometimes it turns out that traditional brick stoves are much more expensive than cast iron.

Among the advantages of cast -iron furnaces “Hephaestus” is highlighted:

- Strength - since the composition of the material allows the furnace to withstand the load, it is stable before mechanical damage and durable.

- The Hephaestus furnaces have a simple design, which allows you not to resort to the help of specialists in the process of their installation.

- It is possible to finish the facade part of the furnace with brick or other materials, although some of its owners do not perform this procedure, and at the same time the furnace also has a good appearance.

- Cast iron furnaces Hephaestus are distinguished by mobility and ease of dismantling.

- In addition, such stoves are universal, since not only heating the room, but heat water for bathing.

- Cast iron furnaces provide the ability to adjust the temperature, in accordance with the desire of people taking bath procedures.

- Although the weight of the furnace is large enough, their transportation does not cause problems.

- If you maintain small fire, the work of the stove lasts for eight hours.

If we compare the stoves made of steel, brick and cast iron, then of course, the last option wins. Cast iron materials are the best conductors, as they quickly heat up and give heat to the room. In addition, the duration of the operation of a cast -iron stove is quite high, since it is very rarely cracking. Unlike a brick furnace, in which a brick is crumbling after a time, requiring a specialist call to replace it.

Cast iron furnaces are more stable before the influence of frost and low temperatures. If you leave the cast -iron stove for the winter in an unheated room, then its qualitative characteristics will remain unchanged.

Comparison in accordance with the heating speed also wins the stove made of cast iron. Within twenty minutes after the kind, the cast -iron furnace is already fully warmed up and begins to heat the room. Brick stoves should first heat up themselves, and only after that heat the environment.

The cast -iron furnace is more compact than brick, it also makes it more convenient to use. In addition, the installation of a brick furnace requires additional design, installation of the foundation and other construction work. For installation of a cast -iron furnace, you do not need to equip the foundation.

Another advantage of the cast -iron furnace for the bath is its safety. The cracks formed on the surface of the brick furnace can lead to a fire. The cast iron furnace can not have cracks, it is quite sealed and safer to use.

If you compare the cast -iron stove with a steel, then anyway, the first option wins. Although steel is stronger and stronger, but in terms of life, it is significantly inferior to cast iron.

In accordance with the exposure of corrosion, the cast -iron furnace is more stable before this process. During operation and severe heating of the furnace, the steel furnace is prone to deformation, and cast -iron is more stable in front of it.

The cost of a cast -iron furnace is less than that of a brick furnace, but more than that of the steel oven, although it wins in quality in quality.

Now let's proceed to consider the shortcomings of the furnace made of cast iron. The cast -iron stove is heated longer than the steel. In addition, she needs cladding, because if water is poured onto its surface, cracks may occur.

To ensure prolonged heating of the room with a steel or cast -iron stove, heating is required using smoldering firewood. For a brick furnace, it is enough just to heat it, and then it will gradually give heat to the environment.

The duration of the operation of the stove made of cast iron is 40%higher than that of the steel furnace, and the utility coefficient reaches 85%. Such a stove can work uninterruptedly up to eight hours, at this time it is not required to put firewood in it, which significantly saves time and improves the comfort of its use.

Cast iron furnace for the bath “Hephaestus” - features and manufacturer

Cast iron furnaces “Hephaestus” are made using a special technology that implies the spill of material in sand quartz forms. Thanks to this, the surface is obtained on which there are no shells, cracks or spaya. The Hephaestus furnaces are completely and completely manufactured in the Russian Federation, all components of furnaces data are distinguished by quality and reliability.

It is possible to equip cast iron furnaces with materials for their facing, such as natural stone, talcochlite. There are several episodes that allow you to clad the Hephaestus cast -iron oven, this is:

- Optima;

- President;

- “Russian steam room”.

The first version of the facing is characterized by the presence of an open box, which is designed to fill the bath stone. Two other options suggest the equipment of a closed box. In addition, the furnace is included in the stove, in which stones are laid.

There is a wide variety of models and forms of cast -iron furnaces. Designers of the company "Hephaestus" will constantly improve products, come up with original functions for cast -iron furnaces.

Studying about the Hephaestus cast -iron furnace, reviews should be highlighted: its advantages should be highlighted:

- durability - manifests itself in anti -corrosion, stability before high and low temperatures;

- the addition of chromium makes the cast -iron stove more heat -resistant, so the duration of its operation is several decades;

- thanks to the use of innovative technologies, Hephaestus cast iron furnaces have a very high efficiency of efficiency, which is more than 85%;

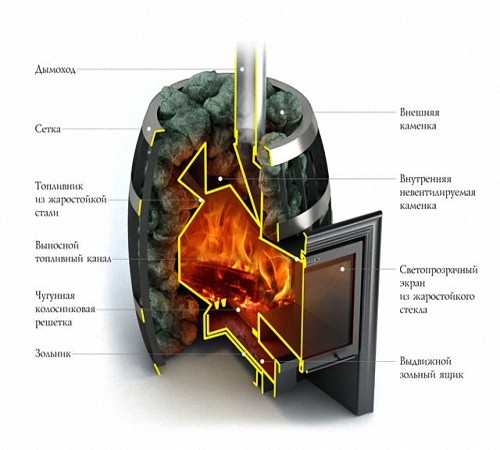

- the design of the furnace is also an innovative development of a company that has no analogues around the world, the furnace consists of three trapezoid cuts that help increase the useful area of \u200b\u200bheating;

- if we compare the Hephaestus cast iron furnace with similar devices, then it differs in the presence of a flame -carrier that helps the movement of smoke gases on the sides of the walls of the furnace, while their additional heating is obtained that promotes the efficiency, therefore, Gephaestus is reasonably using fuel and cools down for a very long time ;

- the thickness of the walls of the furnace is from 1 to 6 cm, they are equipped with vertical stiffeners, convection S-shaped ribs, which contribute to the turning of the rising hot air, thereby making it even hotter.

In addition to the above advantages, the cast -iron “Hephaestus” bake is characterized by a very quick heating steam room or the premises of the bath. Due to the presence of a unique design, the stove can independently heat up to 750 degrees, while the temperature of the smoke inside it will only be 350 degrees.

The Hephaestus stoves are able to retain heat for a long time. The large mass of the furnace contributes to its prolonged heating and maintaining the temperature for several hours.

It is the Hephaestus cast -iron products that can provide a bathhouse with a light steam, which is very useful for human health.

All components that are the components of the Hephaestus furnace are made exclusively from the highest brand of cast iron.

If you make a choice between the Hephaestus cast -iron stove and its gas or electric analogues, it is better to choose the first option. Since when using an electric stove there is no atmosphere of smoke, combustion of firewood and artificial bathing is obtained. To install a gas stove in the bathhouse, coordination of several services, permission and other documents is required. Firstly, this process will take at least a few months, and secondly, it will require considerable monetary investments.

The high -quality stove of the cast -iron bath “Hephaestus” allows you to heat the room adjacent to the steam room, while the person who heating it has the opportunity to enjoy the beauty of the open fire, the smell of firewood and smoke.

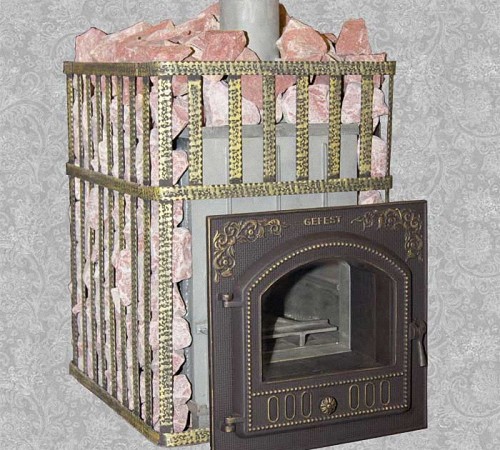

The portals of Hephaestus furnaces have an original finish using artistic casting, the doors are made from heat -resistant materials, while they are glazed, so the beauty of the fire is visible to the naked eye.

As the main facing material for the decoration of the Hephaestus cast -iron furnace, the substance of talcochlorite is used, which contributes to a long -term maintenance of the furnace temperature. When choosing a finish by natural stones, the buyer will receive reliable protection against the influence of infrared rays, which comes from a hot furnace.

Talkhlorite finish allows you to increase the heat capacity of the furnace, since this stone helps to improve thermal conductivity and heat capacity of the unit.

Choosing a series of President or “Russian Pou” cladding, an additional option of the furnace is possible using an internal steam -storage box. The material for its manufacture is stainless steel. Bath stones are installed in this box, steam from which is not able to penetrate into the gaps between the sheets.

The finish using talclorite can not only embellish the appearance of the Hephaestus furnace, but is also characterized by the presence of therapeutic properties that help improve immunity, help the body to confront the flu, and positively affect the general state and health of a person. With the help of a coil, headaches, fatigue are relieved, blood circulation improves and diseases associated with respiratory tracts are treated.

A rather important element of each bath is the shape and arrangement of stones. Stones are laid from the central part. The first stones are the first to put, stones smaller are folded upstairs.

The main condition for choosing stones in the bathhouse is their rounded shape. It is thanks to her that stones are able to maintain the energy obtained from the fire for a long time.

The total weight of stones directly depends on the size of the steam room. For example, to arrange a steam room, an area of \u200b\u200b15 square meters will require 150 kg of stones.

Another important part of the bath is a chimney, if it is installed correctly, then heat will be well accumulated and distributed. Otherwise, there will be problems with the speed of flare and the amount of fuel.

All the Cast iron furnaces “Hephaestus” are equipped with the starting cast -iron chimney, so the problems associated with the breakdown of this particular part of the chimney are excluded.

The main models of cast iron furnaces "Hephaestus"

- “Hephaestus P B 03” - is a small furnace, which is designed for heating with a steam area of \u200b\u200bup to 23 m². Production material - heat -resistant cast iron. This furnace is designed to heat bath or steam rooms, it is a convection device operating on wood or briquette fuel. The furnace chamber is equipped with a special flame cutter, which contributes to the better distribution of heat on the surface of the stove. The presence of a remote portal allows the kindling in the near rooms. In addition, in the configuration to the stove, an forged mesh of decorative purposes is attached. It is designed to lay stones and increases the length of the furnace by several tens of centimeters.

The stove is supplied to the buyer in a distinct form. Such a process allows you to simplify the transportation of the Hephaestus furnace. Installing the furnace does not take much time and does not require special skills, so in the process of its installation, additional involvement of specialists is not required. In addition, the manufacturer in the kit provides a sealant with high -temperature characteristics, which provides additional strengthening of the joints between the steel box for the ash and the furnace. The originality of the design allows you to achieve high furnace performance. To ensure fire safety, there are flamers that can reduce the temperature inside the furnace and in the chimney, thereby reducing fuel consumption.

- “Hephaestus P B 04” - this furnace model is adapted for decoration for brick. It is able to heed the room of the bath or adjacent rooms with an area of \u200b\u200bup to 14 m². The steam produced by the stove is individual and comfortably combines a moderate temperature and humidity. This furnace is a heating convection apparatus, as a fuel for which firewood is used. The furnace is heat -resistant and stable before corrosion. The wall thickness from 1 to 6 cm. In addition, the furnace is characterized by the presence of the upper connection to the chimney, a separate location and the possibility of loading up to 180 kg of stones.