A bourgeois is a furnace that can be made with your own hands from a broken metal. Such stoves were popular at the beginning of the last century, when there was no central heating in houses. Now such stoves are less in demand in apartments and private houses, but they are still used for heating cottages, utility rooms, garages and other premises.

Content

- How to make a bourgeois from a gas cylinder

- On the principle of the work of the bourgeoisie

- A bourgeois from a gas cylinder on wood. About materials

- How to make a potbelly stove and a gas cylinder

- How to make a horizontal type stove-stove

- How to make a vertical type stove-bourgeon

- How to drown a potbelly stove correctly

How to make a bourgeois from a gas cylinder

The easiest and easiest way to make a stove stove is from a gas cylinder. You can buy a furnace in a store, but only as many specialists say, it is not economical and will require a lot of fuel. And if you do not throw firewood or coal in time, it cools quickly. Only 2 outputs remain: either redo the existing stove or make a stove from a gas cylinder on your own.

The task is as simplified as possible, because the case is ready, it remains only to cut the necessary holes, make the legs, pipe and doors. Next - about everything in order.

On the principle of the work of the bourgeoisie

A bourgeois, a racket stove or a portable stove is designed to heat those rooms where there is no way to carry out heating. The bourgeois in the dachas, in sheds, household premises, garages and even greenhouses are installed. If the construction of a new house is being carried out, then a stove-bacon is also used for temporary heating. In principle, the furnace can be installed in any room, provided that the chimney pipe can be brought out, that is, to the street.

The design of such a furnace is quite simple and consists of such elements:

- the top-top building;

- chimney;

- blew.

The advantage of the stove-bourgeois is that this is a simple design that can be made of a gas cylinder. In addition, the furnace is mobile, it can be transported from one place to another to heed the room. The stove is heated in a short time, so a comfortable temperature is quickly achieved in the room. The stove does not take up much space, which is also important.

The only drawback of such heating systems is that the bourgeois is cooing quickly. On the one hand, it is good that the stove warms up quickly, and on the other, fast cooling, it is extra expenses and troubles. But this is not an obstacle if you overcome the stove with a brick on top. If desired, you can slightly improve the standard bourgeois model and add a shelf so that you can heat water and cook food.

As mentioned earlier, the standard stove-stove consists of several elements:

- the lower hole is the channel in the furnace (blown). Air is supplied through it, which is the impetus in order to start the fuel combustion process. This element must have a door so that the user independently monitors the combustion process and its intensity. Ashes are collected inside, which must be periodically cleaned;

- the firebox is the main fuel chamber. It is located above the blow and separated by a grille. There is a door for loading fuel material in the-top chamber. To light up the stove, you need to open the door, and the window was blown to close. Those particles that did not have time to burn - go outside through the hood or return to the blown;

- the third element is a chimney through which combustion products come out of the furnace. In such a channel, there must be a shutter (wedge -shaped) in order to block the channel temporarily, if you need to reduce the combustion intensity of fuel and, accordingly, increase the coefficient of the useful action of the furnace.

This is the principle of operation of a standard stove-stove, but if you make a stove for heating the premises yourself, for example, from a gas cylinder, then the elements in this design will be smaller, since it is advisable to install a chimney separately.

The principle of work of a home -made furnace:

- from blowing, air enters the furnace with burning fuel. Fuel for the bourgeois is coal or firewood;

- combustion products (soot and carbon monoxide) go through the chimney;

- the combustion process can be controlled by opening a wedge -shaped shutter and throttle (open, open completely, close);

- fuel is laid in a special hole located in the gas cylinder of a home -made furnace.

A bourgeois of a gas cylinder. Photo:

A bourgeois from a gas cylinder on wood. About materials

For heating a large room in the area (house, outbuilding, shed, garage, utility room) you will need a large gas cylinder of 50 liters.

You can not talk about the thickness of the walls, they are dense enough to ensure the combustion of any solid fuel. Such cylinders, although voluminous, but not heavy, so even alone you can cope with the task.

As for the choice of material, the best gas cylinder of 50 liters is from under propane. If we consider the cylinders with a smaller capacity (only 10 liters less), then we can say that they have almost the same characteristics, only the volume of the chamber is slightly smaller, but the cylinder is larger in height. The thickness of the walls of such a cylinder is sufficient to make a heating device out of it. Long and narrow cylinders can be useful in order to make a horizontal bourgeois from a gas cylinder:

The composite gas cylinder is not suitable for the manufacture of the furnace, because the material of such a gas cylinder is fiery. As for small cylinders (5 liters), it is better not to start work, because the camera dimensions are small, and the performance of such a furnace will be too low.

As for additional thermal insulation - here the opinions of specialists diverge, because some believe that if you overlap the bourgeois with a brick, then you can maintain heat and the oven will not cool quickly. Others are sure that it is expensive and takes a lot of time. In any case, you decide, because it depends on each specific situation (the area of \u200b\u200bthe heated room, the frequency of operation of the furnace, etc.).

You can also consider this option: the use of empty cylinders for 12-27 liters. They are also suitable, but only for heating small rooms in the area. Such homemade bourgeois can be transferred from one place to another.

After you have decided on volumes, you can start work. You can purchase a gas cylinder in specialized stores, Internet sites, on the market. Choose a cylinder with a valve (there are structures with a valve and a valve) to regulate the intensity of air supply. Such a stove will last longer.

How to make a potbelly stove and a gas cylinder

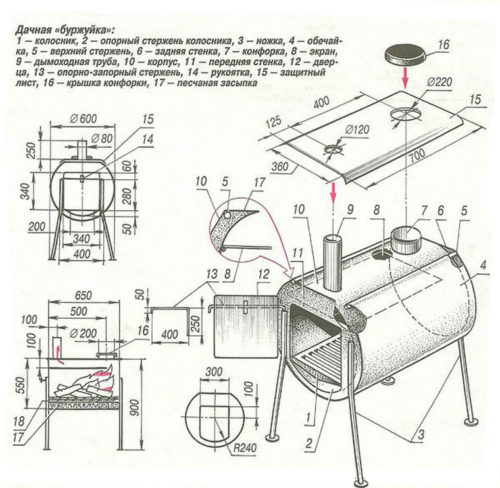

In order to do everything right, study the drawing of the bourgeois from the gas cylinder:

Before starting work, you need:

- The cylinder is completely free from gas. This is done as follows: a valve is unscrewed on the street, the stream should be directed in the opposite direction (opposite from a person and building).

- Wait until all the gas comes out. As soon as the gas stream is exhausted, it is necessary to put the balloon on the side, then turn upside down to remove condensate. It has a very sharp and unpleasant odor, so you need to prepare unnecessary dishes in advance to drain the remains into it. If at least a drop falls on furniture, floor, clothes, hands, it is very difficult to get rid of the smell. Therefore, it is necessary to pour the remaining condensate into the jar, twist the lid, throw it into garbage.

- Put the balloon in a vertical position, pour water to the very top. Thus, the water will supplant the remaining gas and certainly nothing will remain inside.

- The filled gas cylinder must be put on one side again to drain the water.

The capacity is empty, you can without fear of health with the manufacture of a long burning potion from a gas cylinder.

How to make a horizontal type stove-stove

When starting work, prepare all the necessary materials and tools.

The work order is as follows:

- Put a gas cylinder in a vertical position. Now it is necessary to cut the top to the "shoulders". And insert the valve into the formed hole.

- The welding apparatus needs to weld the legs (there should be 4 pcs., For the stability of the bourgeois).

- After the legs are welded, the future stove can be put in a horizontal position.

- At the top where the closed end is cut off, equal to the diameter of the chimney pipe. Around the opening, it is necessary to weld a strip carved from metal, about 5 cm wide. The strip must be welded in a circle of holes, cutting a sheet of metal in the course of work so that it lanes even more. You will get something like a “collar”.

- In the middle of the future furnace you need to insert grates. They must be located transversely. If you work uncomfortable, make a small hole with a cut to insert rods. Or you can do the following: install several shelves inside the design (weld) made of a metal corner.

- On the outside of the cylinder, it is necessary to attach a sheet of steel - it will be a door that closes the hole. It is also necessary to weld a valve and a fitting to provide air blows.

- The door can be hung on the hinges, and it will close it on a small latch. Or another option: on both sides near the hole, it is necessary to attach a belt in the form of a ring to get a small gap. Everything, the door for the furnace is ready.

- The hole for the valve can perform the function of blown, only then it is advisable to additionally install the throttle.

The stove is ready. Following the safety rules, the stove is installed on a sheet of thin steel, 150 per 100 cm in size.

How to make a bourgeois from a gas cylinder - we offer to watch the video:

How to make a vertical type stove-bourgeon

In order to make a vertical device for heating the premises, it is necessary:

- The ventilation hole is cut more than there is 10 cm in the gas cylinder.

- In order for the hole to be as functional as possible, it is necessary to weld a metal plate cut out of a sheet of steel in a circle of the ring, no more than 7 cm wide. This will be the chimney pipe.

- Return 10 cm from the bottom of the gas cylinder (you can 5, only this is the minimum distance from the floor) to cut another hole - for blowing.

- A little higher than this hole, it is necessary to cut one more in the gas cylinder - in order to install the door. The size of the opening for the furnace should be larger than the hole for the blower and a little more than the hole of the chimney pipe.

- To accommodate the rods or a grate, you need to weld the shelves on the gap between the hole for blowing and the door of the furnace, weld the shelves.

- In order to attach the furnace door, weld the loops and put the latch.

To install the furnace in place, a sheet of steel is placed on the floor, 100 by 70 cm, and on top of it-a homemade stake-stake.

Despite the most observed safety regulations, you should always remember that homemade heating equipment poses a threat to human life, because it gradually “eats” oxygen in the room. In order to not be troubles, be sure to ventilate the room.

DIY bourgeois from a gas cylinder. Video:

How to drown a potbelly stove correctly

If you first encounter the operation of a home-made stove-stove, then study these rules:

- The first to go to the furnace, fast -hot fuel is sent. It can be straw, paper or cardboard to warm up the chimney. After heating, the main fuel is laid: coal or firewood.

- A homemade heating unit does not regulate heating, so it is necessary to adapt to the fuel used: to open the door blown, bring the firebox mode to the required level.

- As soon as they heard the characteristic rumble of the furnace, then it can be covered. Then you need to wait a bit while the noise subsides and a light “whisper” of fuel appears. This is a normal working condition of the bourgeoisie.

It is necessary to ensure that there is no empty space on the grill, then the fuel will not burn quickly and give the maximum heat. If there is enough spaciousness, then the air from the blur is absorbed more intensively, and the fuel will burn faster, without heat output.