Anyone who began to build their home from scratch first of all faced a question related to the arrangement of the foundation of the building. Correctly completed work will allow the foundation to serve for a long time, and will become a reliable basis of your home. To achieve the best results, it is important to choose the right and mount the formwork. If you do everything, adhering to all the necessary rules and technologies, then the design will last you for more than a dozen years, and installing concrete formwork with your own hands will save on labor.

Content

General characteristics of concrete formwork

Before starting concrete work, you should pay attention to the method of installing formwork. An important point in the installation of the foundation is the strength of the design necessary to give the form to the base. To decide on a particular type of formwork, it is better to consider each method individually.

Installation methods and materials for concrete formwork

The priority task of formwork is to keep the concrete solution necessary for further hardening and giving various forms of structure. Since the solution is quite heavy, when installing the formwork of concrete structures, additional screeds, brings and spacers are used. They give additional strength to the foundation in the process of hardening. The sizes of the components of the formwork vary depending on the mass of the building and the type of soil.

The following installation methods are used for formwork of the foundation and other concrete structures:

Removable formwork A very popular installation method associated with the simplicity of work and small costs. To give strength to the foundation, use materials that can subsequently be dismantled with further use. To do this, when collecting the formwork, try to reduce the amount of damage to extend the service life of the removable formwork. When assembling such formwork, a moisture -resistant plywood, boards, bars, OSP and other improvised materials are usually used. As fasteners are nails and strips, as well as studs of different diameters that are fixed using nuts.

The following types of materials are used as a material for arranging a removable formwork:

- board (the most common and cheap option. For assembly of the structure, they use wiped boards from coniferous and deciduous wood with a thickness of at least 25 mm. The thickness varies depending on the width of the foundation and its purpose. For example, for monolithic or multi-storey structures, the board is 40-45 mm, and a 25-30 mm board is suitable for a bath or barn, made of such material, a long-term assembly, strengthening and installation process is a low price);

- plywood, OSP, DSP (in the creation of the structure, plywood sheets 1220x1500 or 1220x3000 mm are used, which are fastened to each other using a clay beam 40x40, 40x50 or 50x50 mm. It is better to use a laminated plywood with a thickness of at least 18 mm. Due to the protective moisture resistant layer, sheets can be Apply repeatedly.

The removable version of the formwork is the most common, due to the simplicity of installation and the possibility of using cheap materials. Having completed the assembly, installation and dismantling correctly, you can extend the service life of concrete formwork, and use it in the future more than a dozen times.

Installation non -shaped formwork It occurs in such a way that all the elements holding the shape and size of the solution subsequently remain in their places. They give additional stiffness of the structure. This is a more costly method in which the remaining elements of the formwork can serve the foundation as a heater or waterproofing.

The following types of materials are used for installation of non -stepped formwork:

- metal (expensive material used for formwork in places most susceptible to deformation and displacements. In order to achieve strength of strength, the strapping can be welded directly to metal formwork. Such material is more often used in large -scale projects or on complex surfaces, using wooden beams as a chat for a metal sheet.

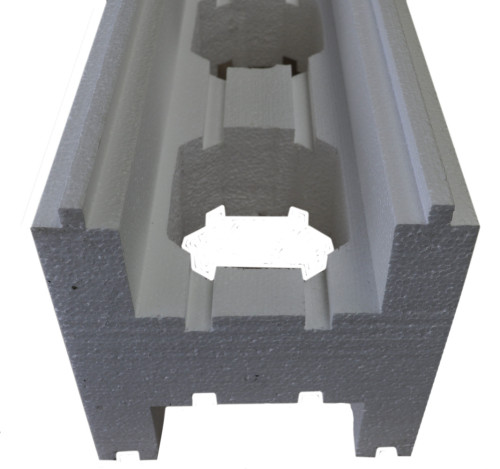

- polistyle foam (used for waterproofing and insulation of the foundation. Such material also has excellent properties of protection against fungus and bacteria, and has excellent soundproofing indicators. Formwork made of such material consists of two sheets of high -density polystyrene, which is fixed using metal brackets and subjects .

- reinforced concrete blocks (used as guides for the foundation of large -sized buildings. To arrange the foundation, tear out a foundation pit in which reinforced concrete blocks are fixed using the spacers. Additionally, the structure is fixed with reinforcement, and then the finished solution is poured into the voids. When the formwork is hardened, it forms it, it forms A single design with the foundation.

To choose the necessary option, calculate the project budget. Think about whether you need the formwork in the future. Perhaps the right decision will be the rental of removable formwork, or the use of improvised materials as an inexpressible option.

Assembly and installation of formwork of the strip foundation

Starting concrete work, pay special attention to the arrangement of the formwork. Concrete formwork for the stairs, foundation or walls made by your own hands will be an excellent solution, since it will not require additional costs for expensive construction brigades. The installation process is quite simple if you adhere to all basic rules and technologies.

Foundation layout

Before collecting and installing the formwork, it is necessary to mark and prepare the site. The strength, reliability and service life of the base directly depend on the correctness of the preparatory work. If you adhere to clear instructions, then the process will pass quickly.

In order to prepare the site for the foundation, it is necessary to perform the following actions:

- Comers the site by removing the upper soil layer by 100-150 mm. You can do this using a shovel. If the site is problematic, then you can resort to the use of heavy equipment.

- Pull the thread around the perimeter of the future foundation. Use metal pieces of reinforcement to achieve the necessary forms and bends. The thread is tied to the reinforcement, and then driven into the ground.

- In parallel to the first thread, pull the second at the required distance. She will determine the width of the future foundation and indicate the location of the formwork.

In order to mark the site, you can draw the future foundation right on the ground. The marking is precisely made - the key to a high -quality installation of formwork. Do not forget to use the plan-scheme of the future foundation, observing all sizes.

The calculation of the material

When buying material for formwork, it is important to correctly make calculations in order to avoid the shortage or excess of raw materials in the future. Counting the required amount of board is quite simple.

To calculate the cubic meter of the boards necessary to create formwork, come as follows:

- Measure the perimeter length. Multiply the resulting value by 2 (since the formwork is located on both sides of the foundation).

- Now, multiply the total length of the formwork by the thickness of the boards used and the height of the foundation (taking into account the allowance).

Consider the calculation of the formwork material using the following example:

- L \u003d 30 m (perimeter length);

- h \u003d 0.5 m (foundation height);

- p \u003d 0.2 m (allowance height);

- n \u003d 0.025 m (board thickness);

- where V is the necessary cubatic.

Thus, the following formula can be derived:

V \u003d l x 2 x n x (h+p) or

V \u003d 30 x 2 x 0.025 x (0.5 + 0.2) or

V \u003d 60 x 0.025 x 0.7 \u003d 1.05 m³

Given the scraps and future spacers, it is better to add 30-40%to the result.

The calculation of the required amount of the beam is made, starting from the height of the foundation and the thickness of the board. Please note that the foundation in each case is unique, moreover, the beam can be replaced with reinforcement. On average, the beam is installed at a distance of 0.7 m from each other.

Installation and strengthening of formwork

First of all, with the independent installation of formwork, pay attention to the installation of the basics. They should be installed in the corners and around the perimeter of the future foundation. A beam or reinforcement is mounted at the same distance from each other from the outside of the formwork. It is better to immediately get a template for cutting the beam to the desired length. The number of necessary supports directly depends on the size of the future formwork and the quality of the soil. To fix the beam, it is enough to deepen it into the soil at a distance of 300-400 mm.

Now it is necessary to nail shields to the established supports that will play the role of the wall of the future formwork. If you use plywood or OSP, then you can immediately start installation. In the case when the board is used, you must first collect the shields. To do this, the boards are laid parallel to each other so that their total width is equal to the height of the foundation, taking into account the allowance. Do this on a flat surface, fastening the boards with each other with a beam. The amount of the required beam is determined by the length of each shield.

When the shields are collected and installed on both sides of the marked foundation, it's time to fix them. Please note that the shields should be strictly parallel to each other in order to achieve the correspondence of the actual size of the foundation with drawing indicators. As you install, check the distance between the shields. To avoid the shift of the walls, the formwork is additionally fixed using the strips that are attached from above, connecting both shields.

In long areas, you can protect the formwork from deformations using additional elements. It is enough to install spacers from the trims of the beam and the boards. To do this, they are driven at an angle into the ground so that the second end rests against the shield at an angle of 45 °.

When the formwork is ready, you can proceed to the process of reinforcing and filling the future foundation. To do this, the reinforcement is placed in a trench and tied. The number of necessary rods is determined by dimensional indicators and other elements of the foundation. When Armopome is ready, you can pour a finished solution.

The following video will help to clearly demonstrate the assembly and installation of formwork: the following video will help:

Adviсe

In order for the processing and installation of the formwork to go as accurately as possible, use the following tips:

- to seal the connections between the boards that occur during the assembly of the shield, use the construction film with a density of at least 60 μN. It will not allow the solution to penetrate the gaps during the filling. And during the dismantling of the formwork, it will not allow the solution to stick to the wood;

- instead of planks that serve as a connection of parallel shields, you can use studs. To do this, in each shield, at the same height, it is necessary to drill two holes, then insert a hairpin into them, fixing on both sides with the help of nuts and washers. Before removing, the studs are removed and can be used repeatedly;

- to connect the formwork elements, use the screw screws for the required size. Unlike nails, they do not rust and get out much easier, without harming the formwork, which perfectly affects the durability of the structure;

- make all preparatory work with maximum accuracy and technology, then the foundation will last you for many years.

As you can see, building a formwork for concrete structures with your own hands in theory is quite simple. To achieve the maximum indicators of the strength of the foundation, they choose an inconspicuous metal formwork. To save time on processing and insulation of the base, a polystyrene version of formwork is used. The most common, acceptable, economical and convenient option will be the installation of wooden formwork. We hope our instruction helped to fully understand the issue of choosing formwork for your future home.