The bar in the house will take a finally completed view after the equipment with the appropriate chairs. When choosing bar for the kitchen, you should take into account their correspondence by style and design with an existing bar. The proposed bar chairs, photos that can be found on the Internet do not always correspond to the designer plan. Having a general concept of carpentry, a small set of tools and a creative approach, you can independently make wooden bar chairs for the house.

Content

Tools and materials for a bar stool from wood

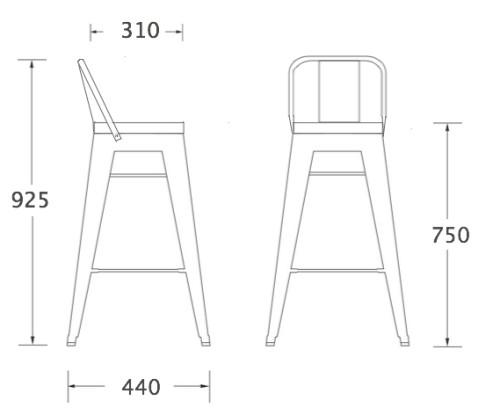

All materials for the manufacture of a bar of wood can be bought at the nearest household store. Some structural elements that you could not make at home can be ordered in a carpentry workshop. To determine the comfortable sizes of bar chairs, the distance from the floor to the lower part of the barn of the bar rack is measured. The gap between the countertop and the chair should be 30 - 35 cm.

- For work, electrical tools will be needed: a drill with drills with a diameter of 3 and 6 mm, a jigsaw, a screwdriver.

- Hammer, rubbish, chisel, roulette, carpentry corner.

- Elevator paper, self -cutting screws (5x20, 5x30 and 5x80).

- Brows - 50x50 and shield massif (tsari) with a thickness of 25 - 30 mm from pine, beech or birch. The approximate diameter of the array for the seat of the bar stool is 360 mm.

- Morilka, varnish, solvent and brushes.

Before starting work, make up the working drawings of a bar stool indicating the exact size. This will help with the determination of the required number of consumables and during carpentry.

The process of manufacturing made of wood stool wood

Guided by the drawings for the manufacture of a bar stool with your own hands, apply marking on wooden blanks with a pencil or marker.

- Using an electric jigsaw, a circle with a diameter of 360 mm is cut out of a wood massif, which will serve as the upper surface of the bar stool. The surface is processed with a grinding machine, and a chamfer is removed along the edge. A circle of smaller diameter, approximately 260 mm, is cut out for installation and fastening of the legs of the chair.

- The seat can be made square from one wide king or made from two to three planks with a width of 120 mm. For fraughting in the longitudinal end side, a spike and a groove are tinted with a milling side. Glued blanks are joined and fixed with clamps are withstanding until completely dry. When gluing, carpentry or furniture PVA is used.

- The legs are made from a beam with a cross section of 50x50 mm. The blanks are pulled out with an electric shirt along the entire length with a small bit. So that the section in the lower part of the legs is 2.5x2.5 cm, and in the upper part, mounted to the seat, it was as thick as possible.

- For a bar stool you will need four pronches. They additionally strengthen the design of the chair and serve as a supporting bar for the legs. A beam with a cross section of 2.5x2.5 cm is plucked and a spike is cut in the end parts. In the legs at an altitude of about 25 - 30 cm from the floor, the nest under the spike is depressed. The sprayers are inserted into the nests on the glue and fixed with twine.

Assembly of a wooden bar stool

Details of the bar stool are collected without cracks and gaps. After fitting the parts, pairs or halves of the chair are connected, and then on glue. Sharp angles of the spikes are slightly rounded.

- In the working mounting surface for attaching the legs, two holes are drilled onto each leg under doughs with a diameter of 6 - 8 mm. The mounting shield should be worn on dads very tight. Additionally, the legs are strengthened by special metal corners in screws.

- A facade seat is attached on top of the mounting shield. It can be fixed with screws from the back of the shield. The bar stool is placed on a flat horizontal surface, and the legs are adjusted. In order for the wood to be not cooked, a chamfer is removed on the ends of the legs.

- A carefully polished, wooden chair for a bar is covered with stain and varnish. For a more aesthetic type, varnish coating is made in two to three layers. After the first and second opening, the surface is treated with fine sandpaper. After the third, it is polished by a felt tampon.

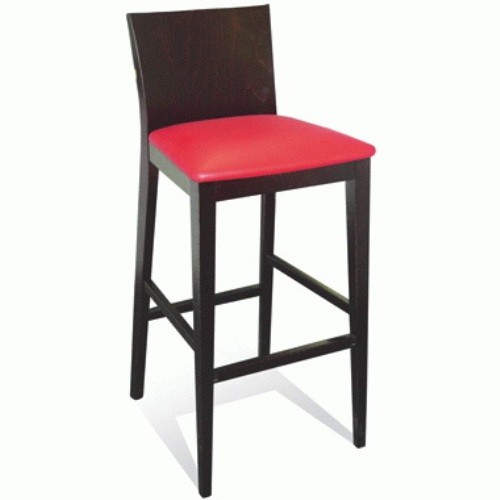

Soft seat and back for bar stool

Sometimes, on a frame -based stool, small backs are mounted for a bar rack, and even armrests. The seat is made soft or half -soft. As a filler, furniture foam or boon is used. Since bar chairs will be used in places of eating, pay attention to the quality and practicality of upholstery. The skin, leatherette, lamb or other upholstery fabric is well suited.

- A thin layer of glue is applied along the perimeter of the seat and from its back. BF-88 glue or furniture PVA is used. The glue is applied to the edges of the foam gasket and along the edge of the output material.

- Having gone a few minutes to thicken the glue, the gasket is tightly pressed to the seat and tightly tightened with an upholstered fabric. From the inside, first in the corners, and then along the entire perimeter, the upholstery is fixed with a furniture stapler. The seat is attached last after the varnish.

- Semi -rounded supporting details and intermediate balusters for the back can be ordered in a carpentry workshop. For their manufacture, you will need a lathe and milling machines. Details are attached to glue and doughs.