The construction of a bath is the first thing for which almost every owner of a country house is taken when arranging a site. Traditionally, a tree was used for its construction, but the variety of the construction market allows you to choose other materials no less suitable for such a building.

Content

What is aerated concrete?

Aerated concrete is one of the types of cellular concrete. It includes:

- cement;

- quartz sand;

- lime;

- gypsum;

- aluminum powder;

- water.

All these elements are mixed and then entered the autoclave, where certain conditions are created for their foaming and hardening.

It is not without reason that aerated concrete blocks for the bath are popular. They have undeniable virtues:

- large size of products with a fairly small weight;

- affordable price;

- environmental friendliness of the material;

- fire safety;

- easy in processing;

- low thermal conductivity;

- do not require a powerful support - a shallow tape foundation enough;

- ease of installation;

- durability.

When using gas blocks for construction, their disadvantages should be taken into account:

- the ability to absorb moisture - it is necessary to carry out both internal waterproofing and a primer of the external walls of the bath;

- cheap blocks often have poor geometry.

Preparation for work

The choice of aerated concrete blocks

The cheaper the material, the worse its geometry. When choosing aerated concrete blocks, the price of which depends on the quality of the material, you should pay attention to factors such as:

- color - it should be homogeneous;

- shape - products with even edges and geometrically correct lines are selected;

- the same sizes of purchased blocks;

- lack of chips and cracks on products;

- method of storage of material - it should be packed in a plastic film.

Tools and materials

During the construction of a bath from gas blocks, tools will be needed:

- electric drill;

- strobores;

- electrophrez;

- hacksaw;

- rubber or wooden hammer;

- carriages and stuks for glue;

- grater;

- level;

- sensor tools.

Of course, it is necessary to buy aerated concrete blocks in the amount calculated in the project and purchase the following building materials:

- cement;

- sand;

- special glue.

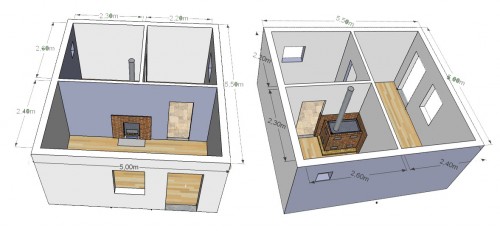

Development of a project of baths

Before starting any construction, they are determined with the layout of the premises. Projects of baths from aerated concrete blocks are ordered from specialists, found on the Internet or make up independently.

In any case, all the nuances should be taken into account:

- the presence of a rest room, vestibule, total number of premises, their location and size;

- communications supply;

- the type of furnace and the method of installation;

- foundation size;

- the presence of a pool;

- the list of building materials and the calculation of their quantity.

The construction of the foundation

A columnar or strip foundation is formed for a bathhouse from gas blocks, but the last option is more reliable and used more often. Squeezed of work:

- Preparation of the base - alignment of the surface.

- Marking according to the project of the bath.

- The formation of a pit 0.6-0.7 m deep and 0.3 m wide.

- Laying to the bottom of the trench of the layers of sand and crushed stone. Their height is 10-15 cm.

- Filling liquid concrete. The thickness of the layer is 10-15 cm.

- Installation of formwork made of wood, plywood, slate or OSB sheets. Checking it for verticality.

- If it is planned to build a reinforced foundation, then along the entire perimeter a frame from the reinforcement of the same diameter is collected. The rods are binded using wire.

- Concrete is poured. For a small bathhouse, there is enough foundation 75 cm high.

- After a few days, after the concrete completely solidified, its waterproofing is carried out. Most often, roofing material sheets are used for this.

When forming the foundation, the presence of a furnace is necessarily taken into account - a rigid base is also required for it.

Masonry of the walls of the bath

- Using the level, the highest angle of the foundation is determined and the construction of the walls begins with it. The first row is laid on the solution. It is with the help of alignment of aerated concrete blocks horizontally. After the solution dries, the surface is treated with a grater and cleaned of dust.

- To ensure horizontal, rails with divisions are installed on the corners and a patching lace is pulled-the next line of the blocks will be equal to it.

- The second and subsequent rows are laid on a special glue, which is divorced according to the instructions presented on the package. For reliable clutch, it is enough to apply the composition with a layer of 0.7 cm.

- Every fourth row of gas blocks must be reinforced. For this, using a cutter, in it, grooves are made around the entire perimeter at a distance of 0.6 cm from the outer edge of the material that are filled with adhesive mixture. The reinforcement is laid in them. It should be completely deepened into the groove and covered with solution.

- Masonry is carried out with a dressing of half the unit. The adhesive mixture is applied to the surface with a carriage or bucket.

- For trimming the unit, electric saw or hacksaw is used.

- U-blocks are used to arrange stiffness and formation of jumpers above the door and window openings. The reinforcement is installed in the product tray and poured with concrete. If the molding is carried out above the opening, then temporary supports are first installed.

- The upper row is strengthened by a monolithic stiffener belt. It is equipped with U-blocks or laying a fixed Mauerlat. On the concrete belt, wire twisting, fixed with anchors - they will keep the rafter system from displacement.

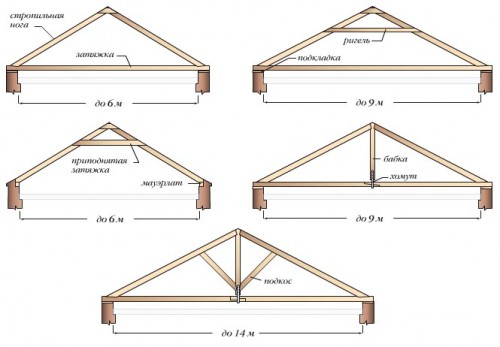

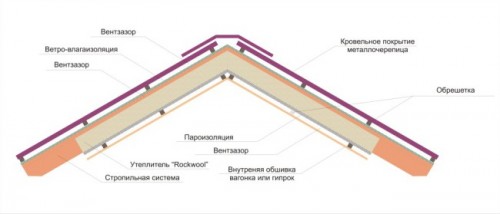

The gable roof of the bath

- A rafter system is installed, consisting of a rafter leg, base and a crossbar. It is made from a trimming board 4x10 cm.

- First of all, triangles of the front -shots of the bathhouse gather.

- The crate is performed. Depending on the roof material, it is made continuous or the bars are placed at a distance of 0.5 to 1 meter.

- The floor of the attic is laid, in which holes for ventilation are made.

- The pediment is sheathed.

- Waterproofing is laid on the crate, and the roof is covered with roofing material.

Bath -finishing of aerated concrete

Bath of aerated concrete blocks, users' reviews of which are quite approving, still requires a special decoration:

- The inner surface of the walls and ceiling is glued with foil. This is done for tightness and the creation of the “thermos effect”. Both self -adhesive and ordinary foil are used. In the first case, it is overlapped, in the second - joints are sealed using aluminum tape.

- A crate is installed to create an air clearance between foil and lining. This will increase the thermal insulation of the structure.

- The walls and ceiling of the bath processed wood are sheathed - most often use aspen and linden. The material of them is not very expensive, but resistant to moisture and has good thermal conductivity. The tree will decorate the bathhouse and create a cozy atmosphere for relaxation.

Outside, a bath of aerated concrete is faced with wooden lining, plastic panels or decorative slabs. Sometimes it is covered with brick, but it is pointless to build the whole building out of it.