Balyasins are not only a supporting element of the railing of the stairs, but also the decoration of the interior. Wooden structures made of expensive wood with a qualified master can become the main object of any room. Handmade balusters made using wood carving technology look especially chic. The ornament or image of the animal applied to the surface of the oak, beech or red tree, look very spectacular and rich. It is no wonder that the stairs in the houses of the European nobility were decorated with carved wood balaisins.

Content

- Why a tree?

- Functions and structure of balusters

- Types of wood bells

- Making wood of wood with your own hands

- Drawings of wood balsin and the creation of a template

- Selection of materials for the production of wood balles

- Flat ballasins made of wood. Production

- Making figurine balusters made of wood

- Balyasins of wood

- Balyasins made of wood: photo

- Balyasins made of wood: video

Why a tree?

Balyasins for stairwells are made from various materials. Marble, concrete, steel - all of them, along with a tree, are quite often found in the production of this construction part. In favor of the tree, its environmental friendliness and excellent appearance speaks. The railing and balusters made of wood can be trimmed with decorative threads. This is a rather soft material that is perfectly processed, which allows you to make real works of art. In concrete balusters or began to apply a decorative pattern, it will be problematic. The tree always organically fits into the interior of any room. Today, balusters from ordinary supports have turned into real works of art.

True, it is worth noting that wooden balusters have their drawbacks. The tree requires great attention. Regular cleaning, the use of antiseptic and antifungal agents - all these works are necessary so that the wood for a longer term pleases you with its beauty. In addition, if the tree is not painted in order to maintain its initial texture, it will be quite difficult to choose a part, in case of its breakdown. Even if you correctly select a tree breed, the shade of the replaced part will be a little different.

Functions and structure of balusters

Balyasins on the staircase march perform three main functions:

- Safety of movement on the stairs.

- Fastening of handrails and railing.

- Decorative decoration of the stairs.

Balyasin itself consists of three main parts:

- Base. This is a usually enhanced part of the balusters, through which the latter is attached to the floor or steps.

- Body. This middle part of the balusters, on which, as a rule, an ornament or curly elements are applied.

- The supporting part. The upper part of the balusters, which is an emphasis for the railing. As a rule, the supporting part in the form resembles a base or in general, is a copy of it. Thus, a symmetrical form is created.

Types of wood bells

Types of balusters are distinguished by the type of trim. They are:

- Flat.

- Carved.

- Milling.

- Crack.

The easiest type of balusters is flat. Such elements are not finished with wood thread or milling. They are a simple beam on which the railing is installed. Carved balusters have the most complex artistic elements. The thread is applied manually, which allows you to decorate the support with a more complex ornament. Milling is carried out on special milling or turning machines. This method helps to create rather beautiful elements with smaller ones than when carving, labor costs.

Making wood of wood with your own hands

The manufacture of balusters is a rather complicated and laborious process. It requires knowledge of the basics of woodworking and practical skills in this matter. The beginner needs several months of preparation to make several identical figured elements that would be one.

Also, special equipment is needed to carry out these works:

- lathe,

- milling mill

- set of chisels,

- electrician,

- drill,

- scurgery.

Drawings of wood balsin and the creation of a template

The size of the balusters and their number will depend on the configuration of the stairwell. The height of the railing, as a rule, is from 80 cm to 1 m, respectively, this should be the length of balusters. Based on the length of the stairwell or balcony, which will be fenced with the railing, the number of elements is calculated. The lumen between the two racks of the fences should not exceed 10-30 cm, while it is necessary to ensure that the balusters are installed at an equal distance from each other and form a single composition. Also, when forming a sketch, it is necessary to take into account the angle of inclination of the stairs. Depending on it, the supporting part of the balusters will be cut into which the railing will be mounted.

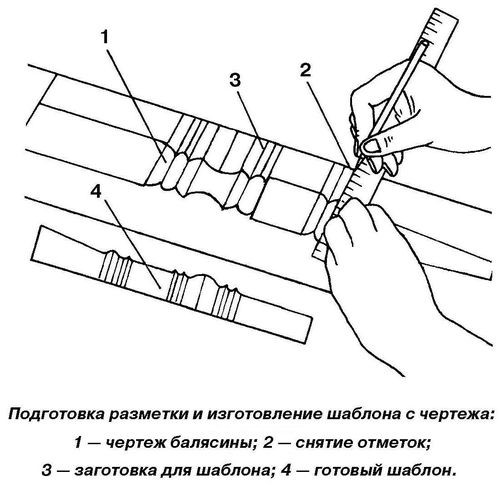

When all the calculations are made, and the dimensions of the balusters are determined, we proceed to the sketch of the sketch. On it, we display those elements that will be applied to a wooden workpiece. In details, you need to depict all parts of the balusters in order to subsequently create a template. It is necessary to achieve the same details throughout the staircase march. As the template is created, suitable incisors for a lathe are selected, with which the workpiece will be sharpened.

If the design of the stairs involves the presence of ballasts of different height and appearance, you will have to make several templates. Recently, asymmetric stairs have become quite popular, in which these structural elements are different in texture and size. In this case, there is no point in making a template.

Selection of materials for the production of wood balles

This is the most important point in the manufacture of stairwells and their structural elements, which include balusters. As a rule, for their production, solid woods are used, such as:

- Oak.

- Ash.

- Larch.

- Birch.

- Beech.

Of course, you can use soft wood, such as pine. However, despite all the amenities in its processing, it has an extremely low margin of strength, respectively, the number of elements should be larger with equal load.

The combination of metal elements made of steel, aluminum and bronze in one product is currently very popular in the production of staircases. It looks great ballyasin from dark cherries in combination with bronze inserts. Also, the metal is used as the base and the supporting part, when the railing or stairs are not made of wood. For example, the floor of dark marble, the base of the balusters and its supporting part of curly bronze, and the body of balusted oak, railing made of forged iron. Often combination and metal is made if the staircase is installed in a busy place or on the street. In this case, the wooden insert will not “pull” moisture from the floor.

Flat ballasins made of wood. Production

For the manufacture of flat structures, the presence of special skills and knowledge, as well as a special tool, is not required. The whole process consists in cutting a certain size using an electrolobian of bars. After that, the workpiece is polished using a manual grinding tool or nozzle for a drill (screwdriver). With the help of a rubbish, you can remove sharp corners, which are later also polished.

If there is the possibility of a suitable tool (hand cutter), you can make a simple milling. After processing, flat balusters with their own hands are opened with stain and varnish.

Making figurine balusters made of wood

As a rule, curly balusters make a round shape with a smooth or sharp transition from large to small diameters and vice versa. For the production of such figures, special equipment is necessary - a current machine, as well as construction cutters.

The principle of operation of the lathe is the processing of the part rotating with a certain speed, which is fixed in the spindle of the machine. A special cutter is fixed on its caliper, which, when serving to the part, removes several layers of wood from the workpiece.

Each cutter “is responsible” for a certain element that will be carved on the beam.

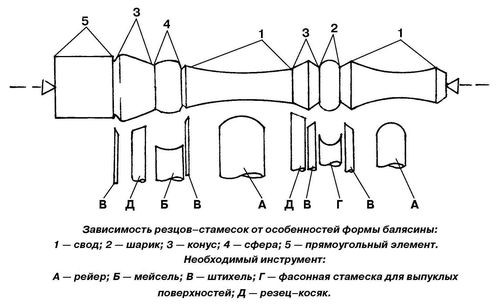

The main types of incisors and their purpose:

- Reyer. This cutter is a wide sharp surface with the end in the form of a convex arc of a circle. Designed for lifting the arches.

- Meysel. The opposite of the Reyer. His arc is concave inside. Need a cutter for pulling the balls.

- Stikhel and a cut-kosyak. They resemble a chisel inverted by the end. Such incisors are used to pull out cones.

- A shaped chisel. There are a large number of them depending on which element must be coated.

For the convenience of manufacturing a large number of identical parts on lathes, copiers are produced. It is a template made of solid material, most often from plywood on which a caliper walks. The template should be the "negative" of the detail that you want to get in the end. For example, concavity on the template will make a bulge on the workpiece and vice versa.

Balyasins of wood

Like most wooden products, balusters require careful attention, and only then will they bring joy and serve for a long time.

Balyasins are regularly cleaned of dust. If the garbage and dust will cover the varnish for a long time, then over time it will fade. To give these elements of shine, they must be treated with special polishes. Over time, balusters can shat. In this case, in order to avoid destruction and deformation, it is necessary to fix it using nails or screws installed at an angle of 45 °. Install the fasteners so that his hat is drowned in a tree. Later, the hole must be putty, and all the balusters are opened again with varnish and stain.

In the case of cracking of the tree, the crack is filled with special glue and pulled together with painting tape. When the glue dries, the tape is removed.